4

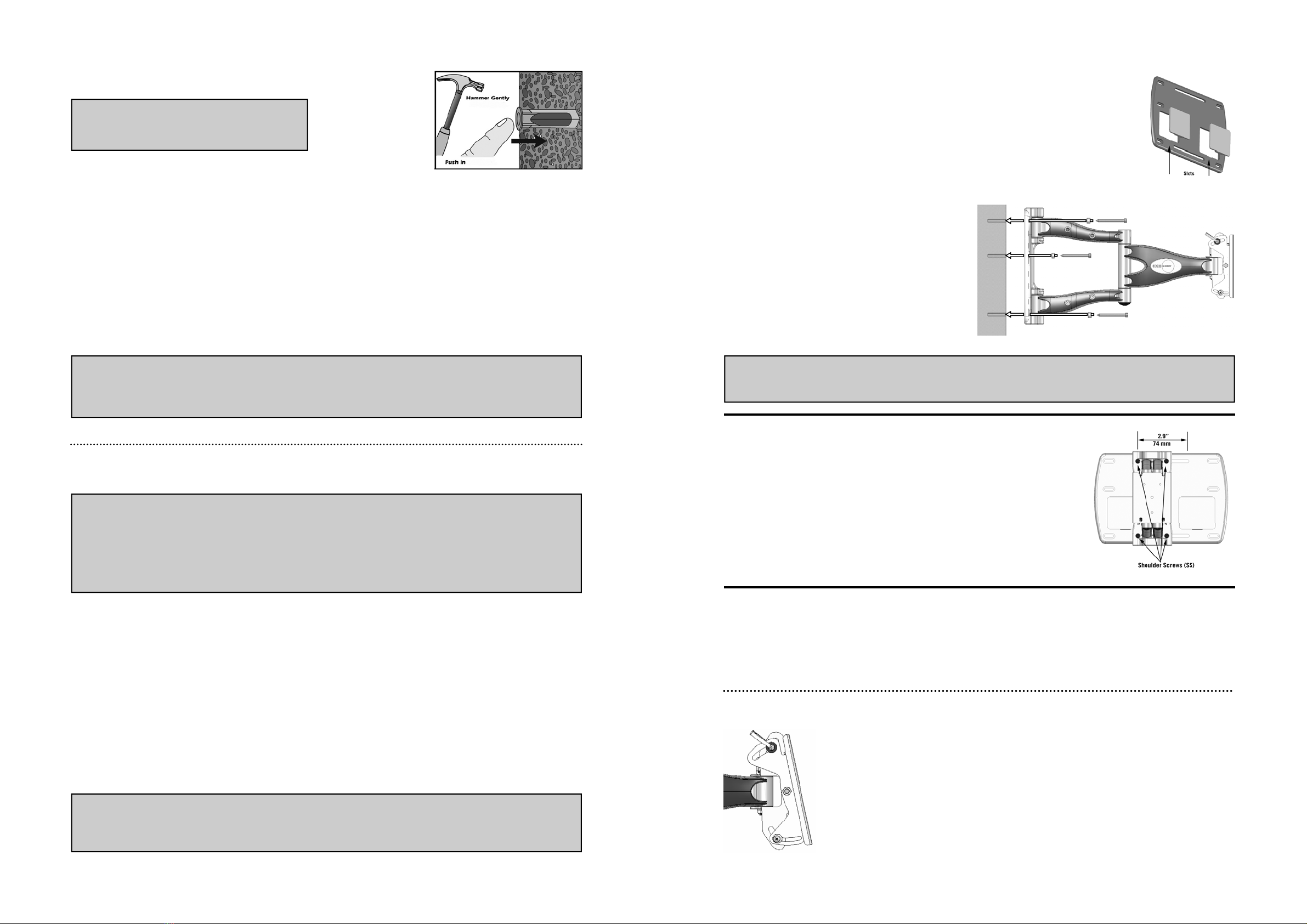

Step 3b — Mounting to Concrete/Masonry

The wall plate can mounted directly to concrete/masonry walls.

Remove the tape strip from the back of the template, and place the template in the

desired location. Using a bubble level, hold the template in a level position and then press the adhesive backing against

the wall to hold the guide in place.

Note: Depending upon the roughness of the surface, you may need to hold the template in place with an additional appli-

cation of tape or blue painter’s tape.

Using a 1/2” (13 mm) masonry drill bit, drill 6 mounting holes 3 1/8” (80 mm) deep into the concrete/masonry surface.

Drill through the mounting hole cut-out sections of the template.

Note: For best results from the dust channel, press and hold the template against the wall about 2” (50 mm) from where

you are drilling.

Carefully remove the guide from the wall, and discard. Note: Be sure to hold the guide in an upright position so as not to

spill the collected dust.

Insert wall anchors into the mounting holes, and lightly tap them flush to the wall with a hammer. (Fig. 3)

WARNING

• NEVER drill into mortar joints!

• Concrete must be 2000 PSI density minimum.

IMPORTANT

Masonry anchors MUST be seated firmly against the concrete or masonry. If mounting to a masonry wall covered with drywall/

plaster, counter bore a hole through the drywall/plaster around the mounting hole location, so that the anchor can be seated di-

rectly against the concrete or masonry.

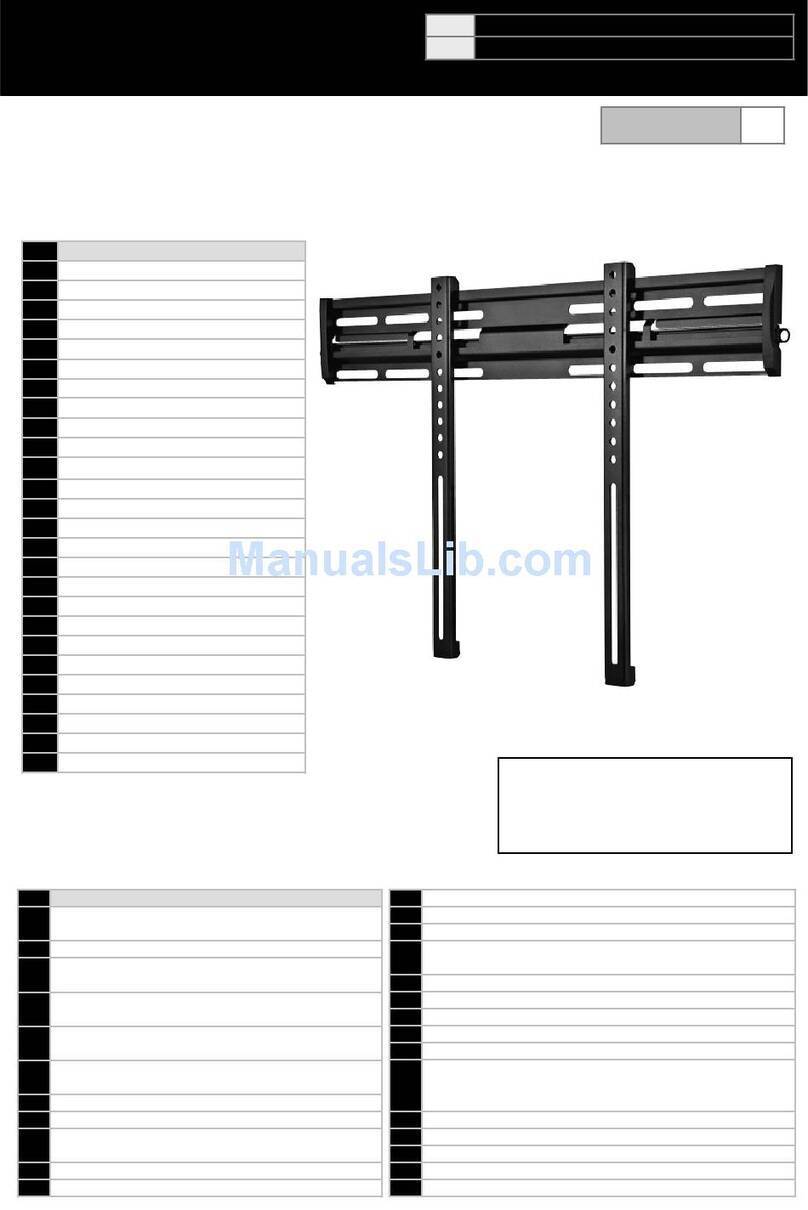

Fig. 3

Step 3c — Mounting to Cinder Block

The wall plate can mounted directly to cinder block walls.

Remove the tape strip from the back of the template. Using a bubble level, hold the template in a level position and then

press the adhesive backing against the wall to hold the guide in place.

Note: Depending upon the roughness of the surface, you may need to hold the template in place with an additional appli-

cation of tape or blue painter’s tape.

Using a 1/2” (13 mm) drill bit, drill 6 mounting holes 3 1/8” (80 mm) deep into the cinder block surface. Drill through the

mounting hole cut-out sections of the template.

Note: For best results from the dust channel, press and hold the template against the wall about 2” (50 mm) from where

you are drilling.

Carefully remove the guide from the wall, and discard. Note: Be sure to hold the guide in an upright position so as not to

spill the collected dust.

Insert wall anchors into the mounting holes, and lightly tap them flush to the wall with a hammer. (Fig 3)

WARNING

• Cinder Block must meet ASTM C-90 specifications.

• Mount to solid portion of block, generally 1” from the sides.

• NEVER drill into mortar joints!

• Use standard drill set on slow speed/ high torque setting. DO NOT use hammer drill on cinder block.

• Verify that you have a minimum of 1 3/8” of actual concrete thickness in the mounting hole, before inserting the wall anchor.

IMPORTANT

Masonry anchors MUST be seated firmly against the concrete or masonry. If mounting to a wall covered with drywall/plaster, counter bore a

hole through the drywall/plaster around the mounting hole location, so that the anchor can be seated directly against the concrete or masonry.

5

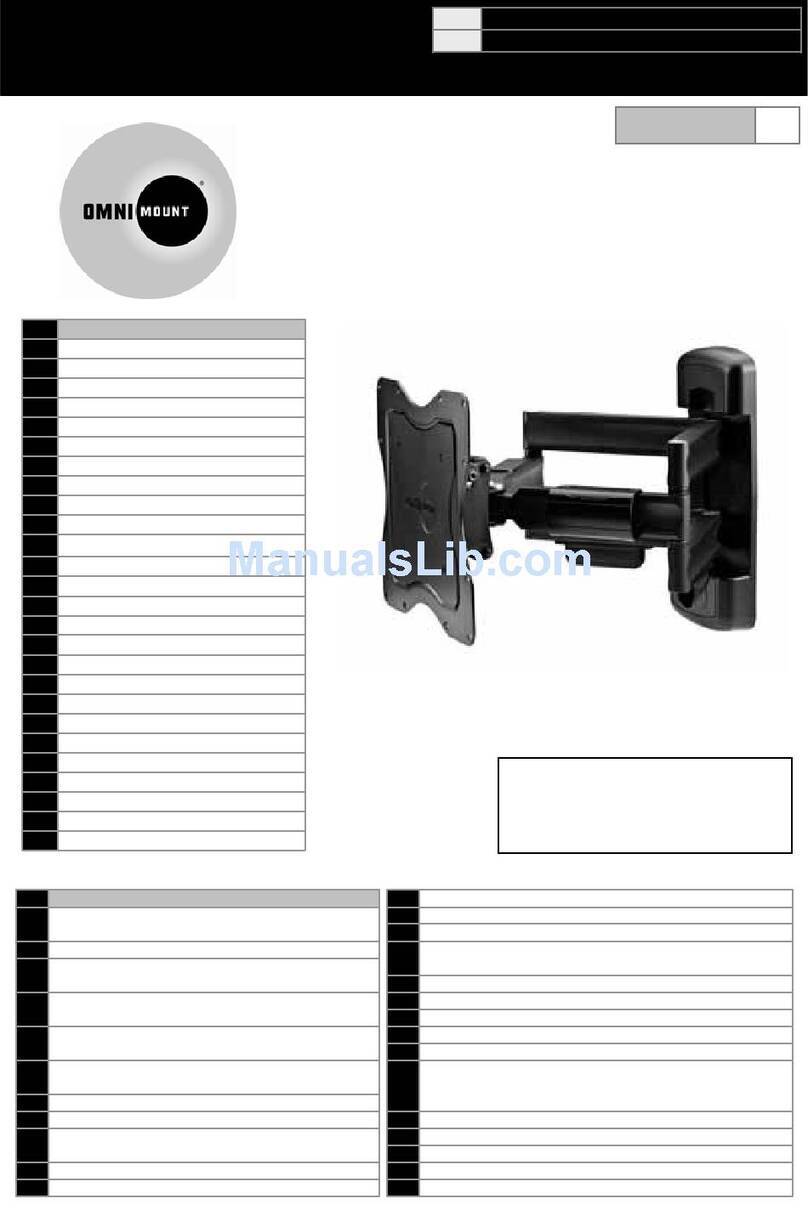

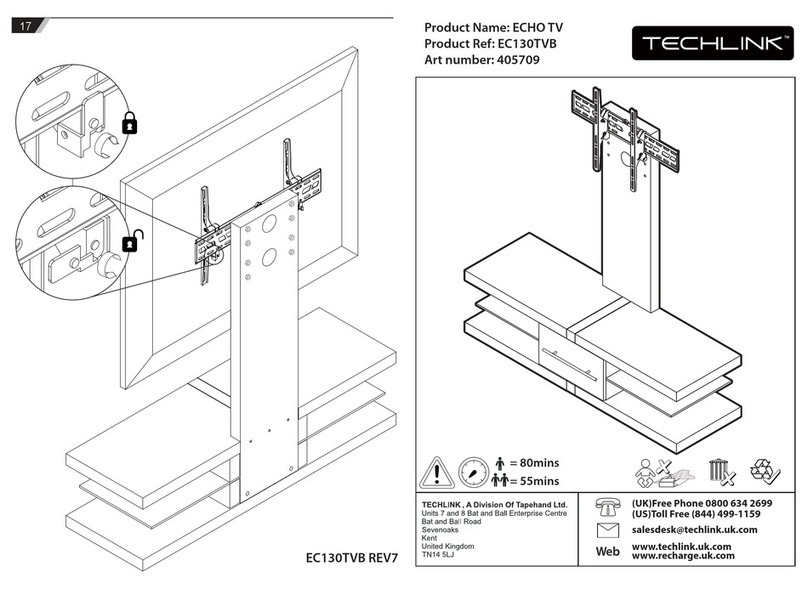

Fig. 4

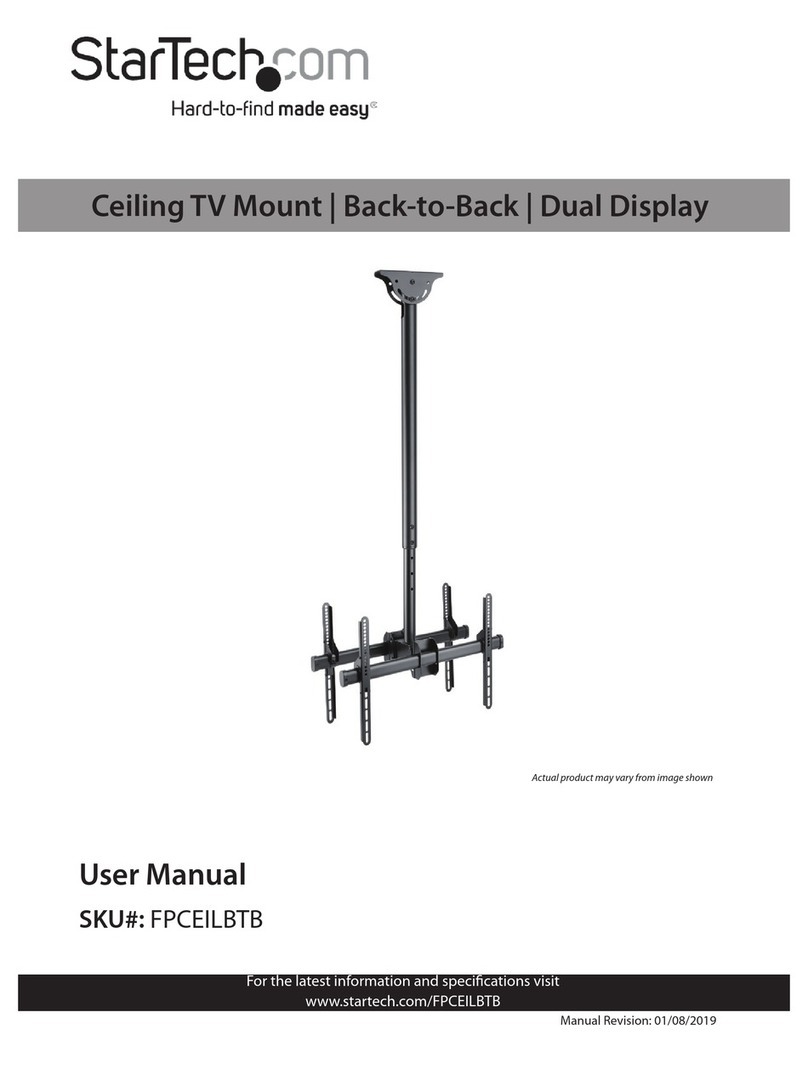

Step 4 — Mounting to the Wall

Remove the cantilever assembly from the box.

If you have installed electrical boxes into the wall, you will need to remove the Cover Panels from

the wall plate before proceeding. Insert a flat bladed screwdriver into the slots on the bottom of the

plastic cover panels, and carefully pry them from the wall plate. See Fig. 4.

Note: The arm assembly has been removed from Fig. 4 for

clarity. DO NOT remove the arm assembly from the wall

plate prior to mounting the wall plate to the wall.

With the help of an assistant, carefully hold the mount in

position over the mounting holes, and then securely bolt the

wall plate to the wall with supplied spacers (1) and 3/8” lag

bolts (2). See Fig 5.

IMPORTANT

Tighten lag bolts so that wall plate is firmly attached to wall, but DO NOT over tighten. The Lag bolts can be damaged by over tightening,

which greatly reduces their holding power. Final tightening of lag should always be done by hand, with a ratchet wrench and socket.

Fig. 6

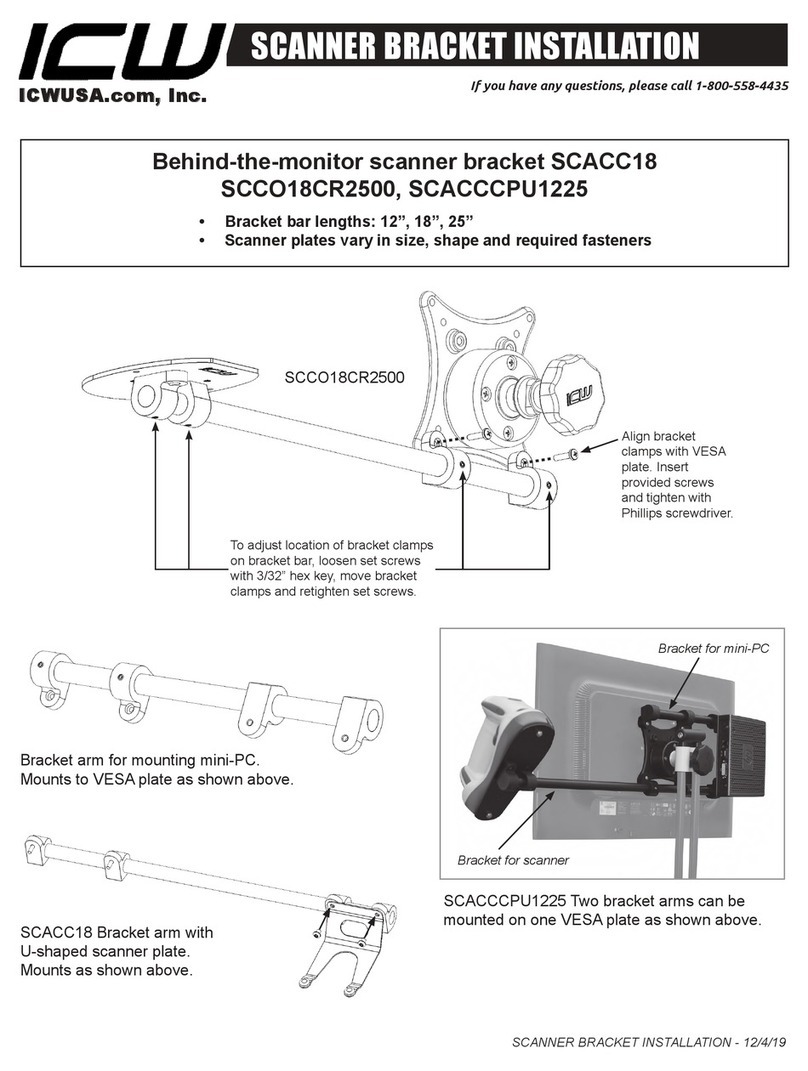

Step 5 — Adjusting Lateral Arm Position

Once mounted, the lateral position of the arm assembly can be adjusted left or right by

sliding it across the wall plate. The total range of adjustment is 2.9” (74 mm), as

shown in Fig. 6.

To move the arm assembly, loosen the four shoulder screws (SS) with the Large sup-

plied hex wrench. Carefully slide the arm assembly into the desired position, and then

securely tighten the shoulder screws.

To attach a flat panel display to the mount, you will need an optional adaptor plate. Follow the instructions included with

the adaptor plate to attach the display.

Step 6 — Attaching the Display

Fig. 5

Fig. 6

CAUTION: WHEN REMOVING THE DISPLAY MAKE SURE THE HEAD IS

LOCKED IN THE NEGATIVE TILT POSITION, OTHERWISE INJURY COULD

OCCUR.

Negative Tilt