LV8702VSLDGEVK

www.onsemi.com

10

xample 3: Rotating the motor 180 degrees

Transfer Unit = Degree

Transfer Angle = 180 [degree]

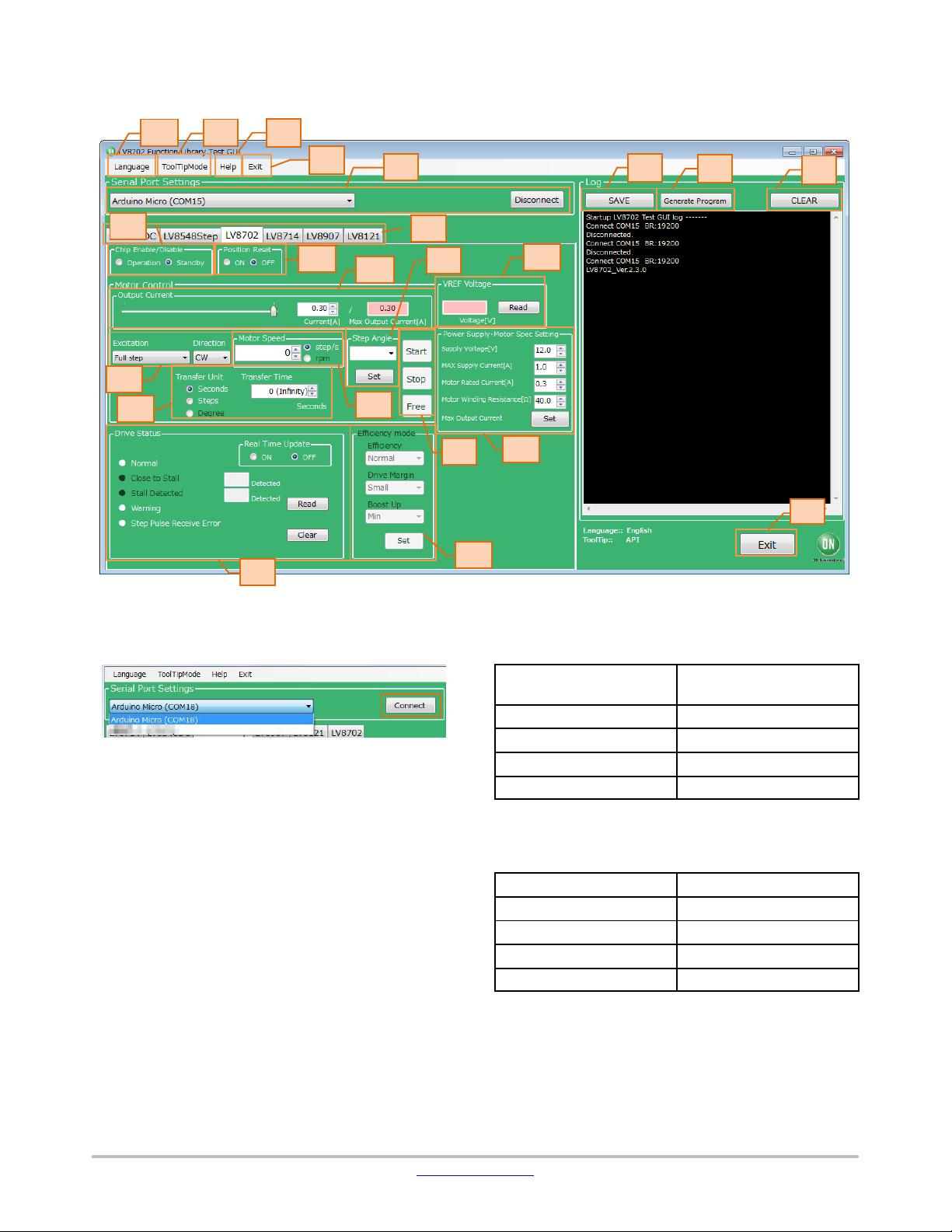

9. When the Start button is pressed, the motor will

rotate. If changes to the Output Current, Excitation

or Motor Speed are made, the changes will take

effect upon pressing the Start button.

To change the direction of rotation, it is

recommended to stop the motor first with the Stop

button, change the value, and then press the Start

button to begin the motor rotation.

Pressing the Stop button causes the motor to stop,

and hold the torque.

When the Free button is pressed, the motor will

stop and lose the torque.

To maintain the position while the motor rotates,

or to pause the motor and restart from the same

position, select the Stop button.

At this time, because of the current still flowing

to the motor, attention must again be paid to

heat generation.

10. Set the specifications of the power supply and

motor to be used.

Supply Voltage... Power supply voltage

MAX Supply Current... Maximum power supply

current

Motor Rated Current... Motor Rated Current

Motor Winding Resistance... Motor coil resistance

Max Output Current Set buttons ... Calculate the

maximum output current from the above four

setting values, and 5 limit the set range of the

output motor current to enable safer motor driving.

11. Set the high−efficiency drive function.

(This function does not work in slow speed and

fast speed range where the feedback signal can’t

be stably detected. This function cannot be

selected when Full Step is set.)

The high−efficiency drive function automatically

optimizes the motor current according to the motor

load and rotational speed. By turning on this

function, power consumption, heat, vibration, and

noise can be reduced. The high−efficiency drive

function consists of the following three

parameters.

Efficiency... ON/OFF of high−efficiency drive

function

When the high−efficiency drive function is turned

on, the motor current is automatically adjusted

within the range of the limit set in 5.

Drive Margin... Margin adjuster Function

Adjust the margin from the minimum current that

can rotate the motor.

When the margins are set to Small, the current

consumption is the smallest, but the number of

boost−ups may be increased for small

load−changes.

For this reason, set the margin to be larger for

applications with excessive load variation.

Drive Margin

Current

Consumption Robustness

Small Low

Normal

Weak

Strong

Middle

Large

Boost Up... boost−up adjuster function

This process increases the motor current rapidly

and temporarily in order to maintain the motor

rotation in response to load variation.

Increasing the boost increases the rush load

resistance, but increasing the boost increases the

rotational stability.

The worsened of rotational stability can be

suppressed by increasing the Drive Margin.

Boost Up Robustness

Rotational

Stability

Min Weak

Strong

Stable

Unstable

Low

High

Max

12. Set the reset function.

The reset function resets the excitation position

and locks the motor.

[ON] ... Reset ON

[OFF] ... Reset OFF

Neither is turned off the power.

13. Voltage reading function

14. Status check function

15. GUI Language Settings

16. GUI Tool Tip Display

17. Help function

(See Appendix for more information)