Onan CCK User manual

Other Onan Engine manuals

Onan

Onan L Series User manual

Onan

Onan B43M User manual

Onan

Onan Elite E125V User manual

Onan

Onan Performer P216 User manual

Onan

Onan DJBA Series Instruction Manual

Onan

Onan NHC Series Instruction Manual

Onan

Onan RDJE User manual

Onan

Onan NHC User manual

Onan

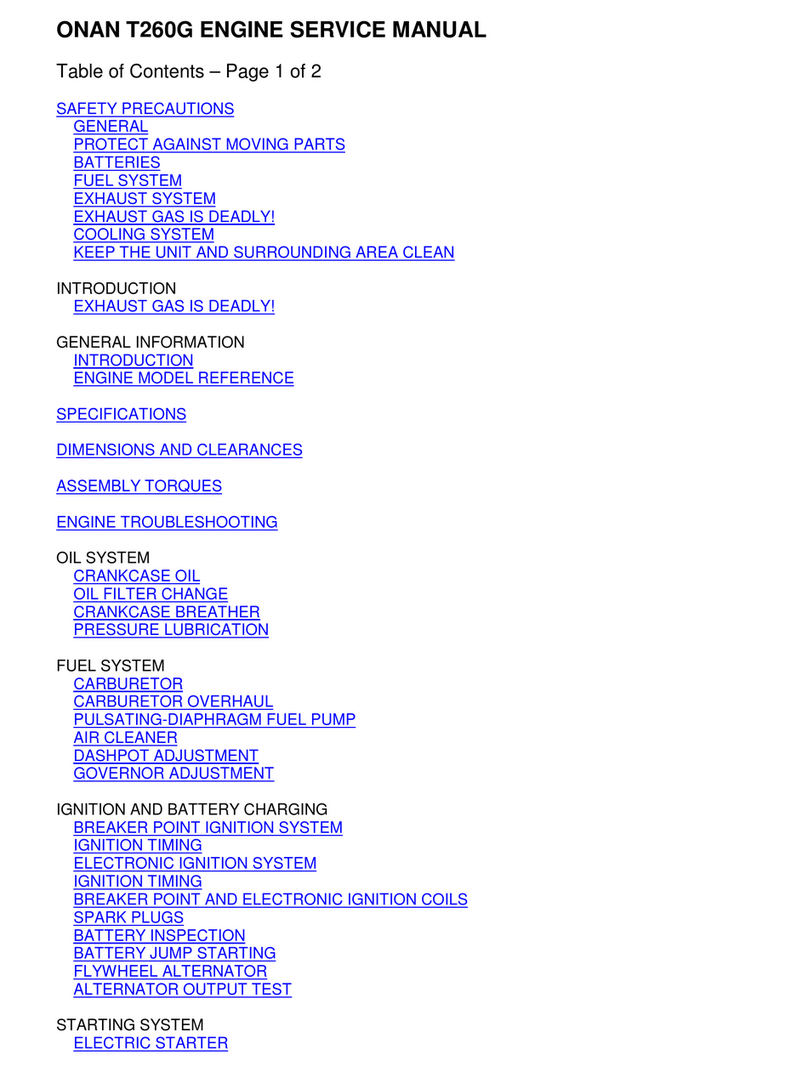

Onan T260G User manual

Onan

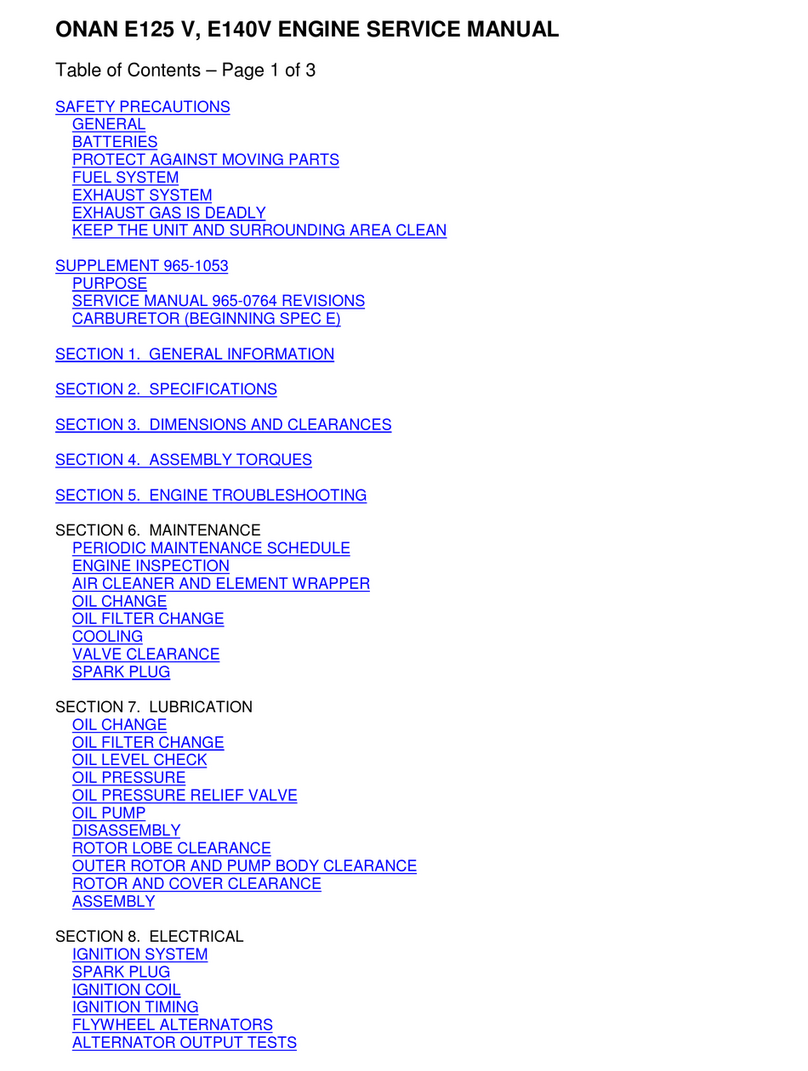

Onan Elite E125V User manual