WELD THE WORLD

Cod. 006.0001.1380

08/09/2021 V.2.8

Multi Power 184

3

ENGLISH

INDEX

1 INTRODUCTION.......................................................................................................................................... 4

1.1 PRESENTATION.......................................................................................................................................... 5

2 INSTALLATION .......................................................................................................................................... 6

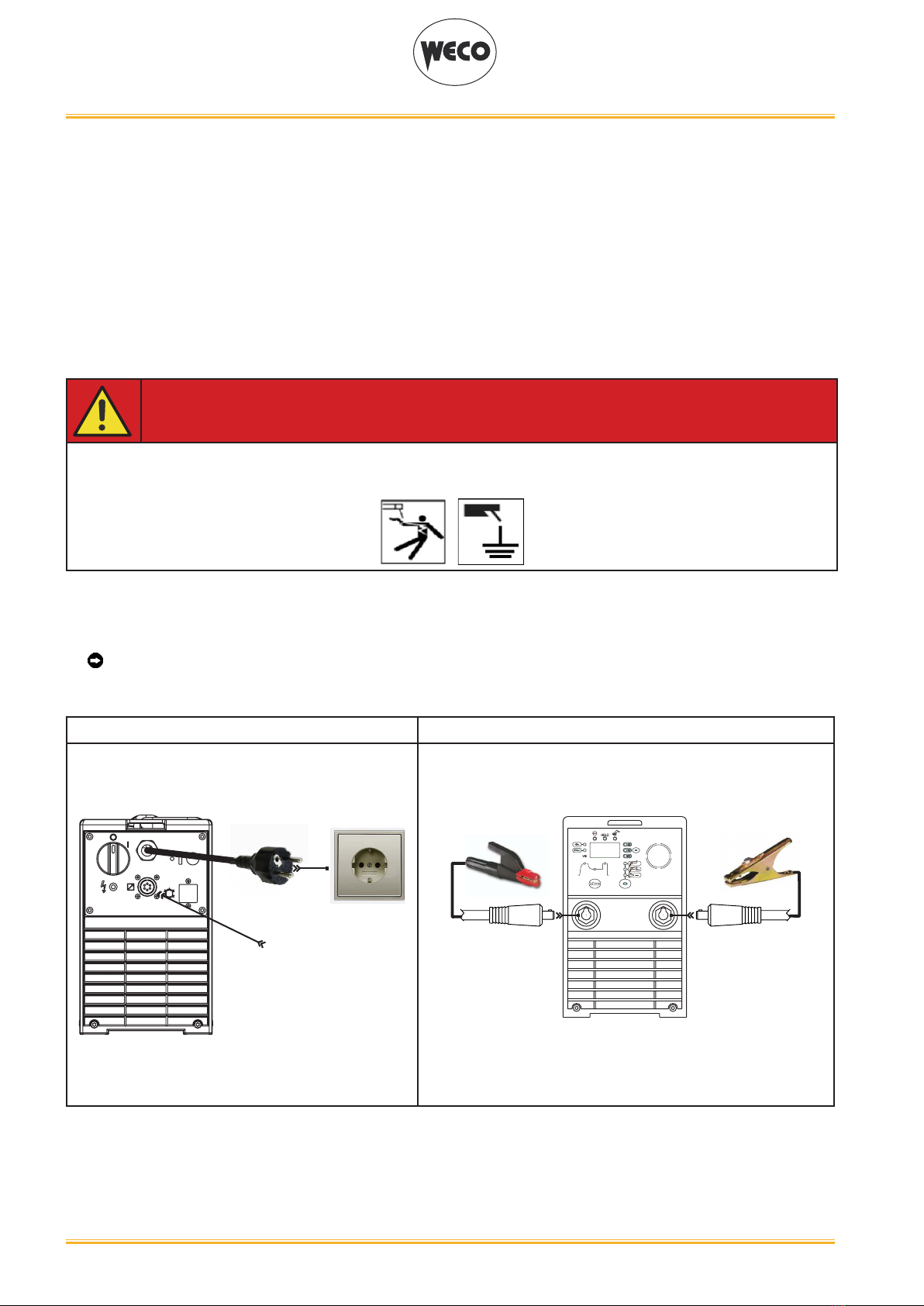

2.1 CONNECTIONS TO THE MAINS POWER SUPPLY .................................................................................. 6

2.2 FRONT PANEL............................................................................................................................................. 6

2.3 REAR PANEL............................................................................................................................................... 7

2.4 PREPARING FOR MMA WELDING............................................................................................................. 8

2.5 PREPARING FOR TIG WELDING ............................................................................................................... 9

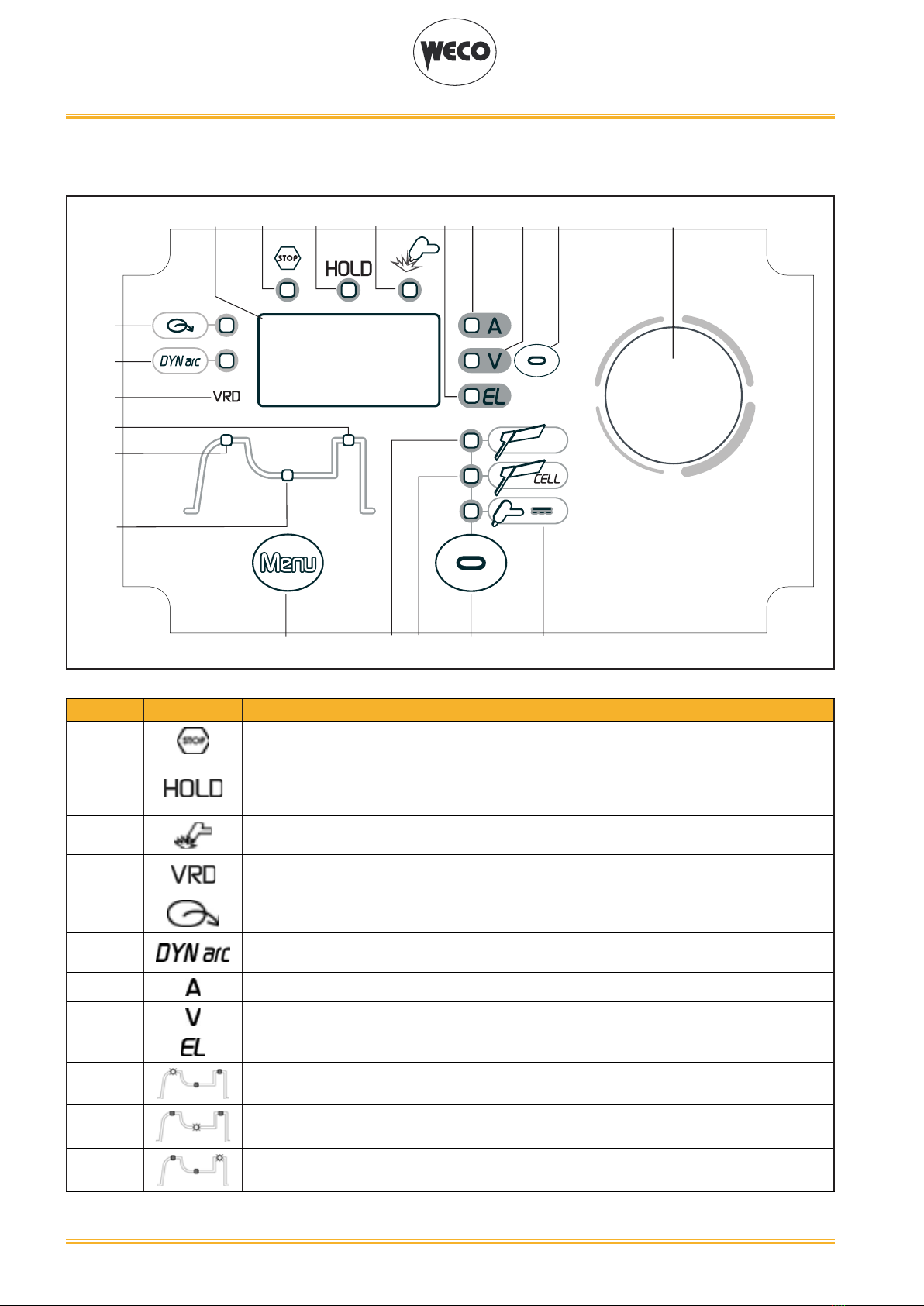

3 USER INTERFACE .................................................................................................................................... 10

4 UNIT POWER-UP ...................................................................................................................................... 11

5 RESET (LOAD FACTORY SETTINGS)..................................................................................................... 13

6 ALARM MANAGEMENT ........................................................................................................................... 14

7 DERATING................................................................................................................................................. 15

8 ELECTRODE WELDING (MMA)

CELLULOSE WELDING (MMA CEL) ....................................................................................................... 16

8.1 MMA / MMA CEL WELDING - FIRST LEVEL MENU ................................................................................ 16

8.2 MMA / MMA CEL WELDING - SECOND LEVEL MENU ........................................................................... 18

9 DC TIG WELDING ..................................................................................................................................... 20

9.1 DC TIG WELDING - FIRST LEVEL MENU ................................................................................................ 20

9.2 TIG DC WELDING - SECOND LEVEL MENU ........................................................................................... 21

10 TORCH TRIGGER PROCEDURE ............................................................................................................. 22

11 TECHNICAL DATA .................................................................................................................................... 23

12 WIRING DIAGRAM.................................................................................................................................... 25

12.1 REMOTE CONTROL CONNECTOR (back panel)..................................................................................... 26

13 SPARES..................................................................................................................................................... 27