windings,isfedtothevoltageregulatorasa reference

voltageformaintainingthegeneratoroutputvoltage.

TheACreferencevoltageisconvertedtoDCbya

siliconcontrolledrectifierbridgeonthevoltage

regulatorprintedcircuitboardandfedintotheexciter

fieldwindings.Theexciterarmatureproducesthree-

phaseACvoltagethatisconvertedtoDCbythe

rotatingrectifierassembly.TheresultantDCvoltage

excitesthegeneratorrotorwindingtoproducethe

statoroutputvoltagefortheAC

load.

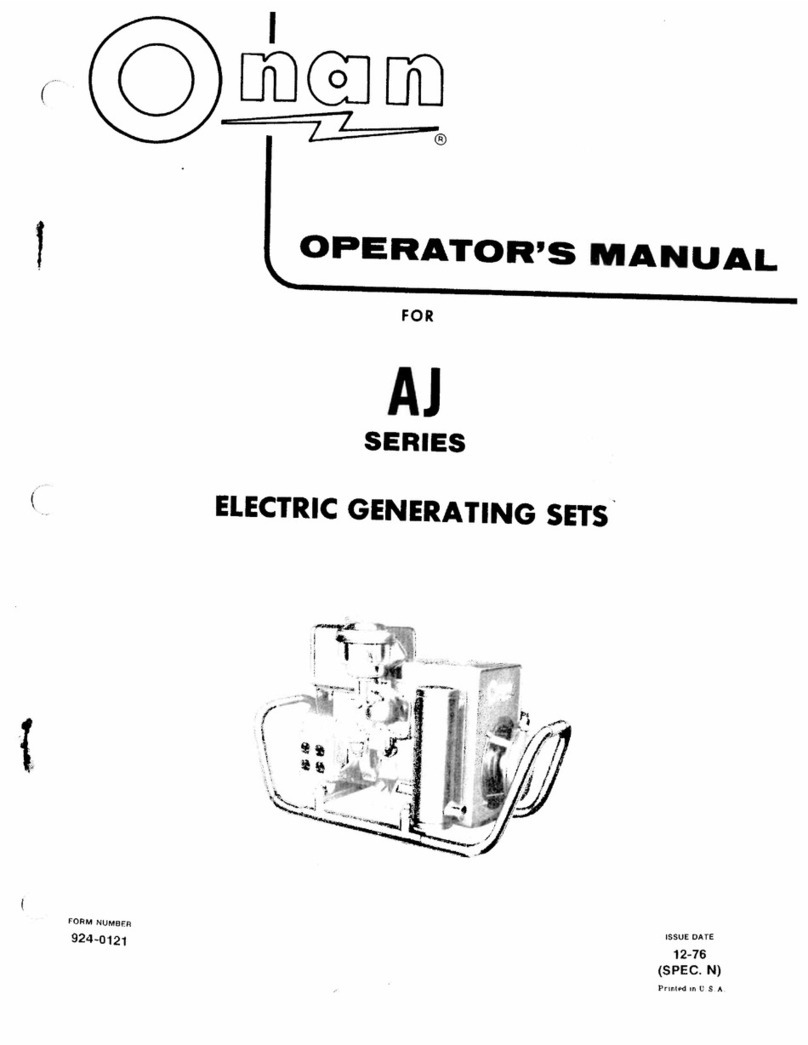

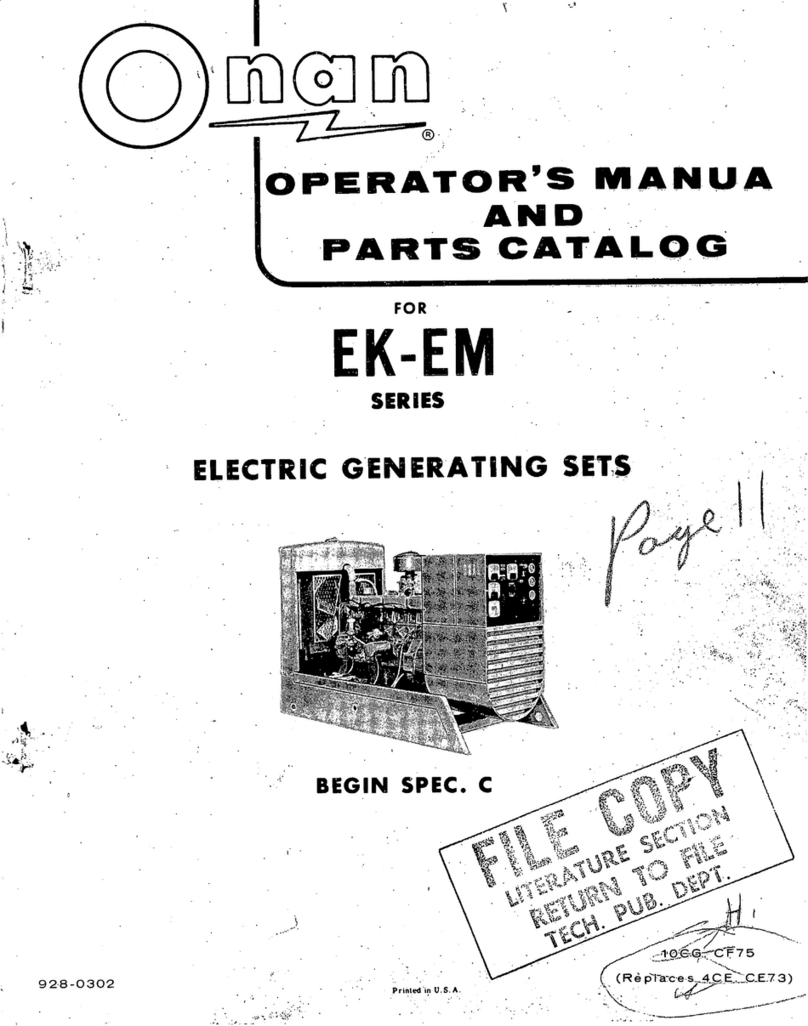

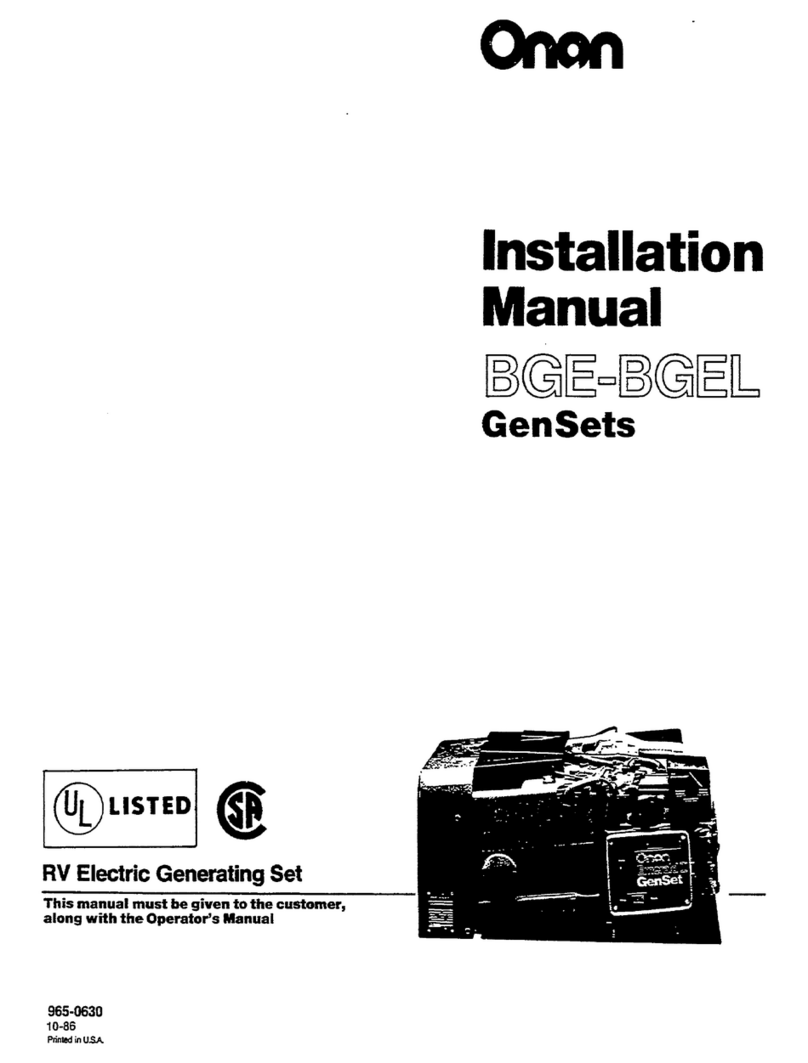

VOLTAGEREGULATOR

LOCATION

WIO

0

VR2I

®

T2I CMR2I

REFERENCE

VOLTAGE

TRANSFORMER COMMUTATING

REACTOR

TB2I9

NOTE:

FIELD

BREAKERIS

MOUNTEDON

PANEL

FIGURE2..VOLTAGEREGULATOR

ThegeneratorrotoralsoproducesACvoltage(19to

21volts)inthechargingwindingofthestatorwhichis

convertedtodirectcurrentforbatterycharging.

VOLTAGE

REGULATOR

(Spec

AA)

Theline-voltageregulatorontheJ-seriesgenerator

setsisanallsolidstatedevice;thatis,norelaysor

tubesareneeded.Basiccomponentsofthevoltage

regulatorare:

•PrintedcircuitboardVR21

•VoltagereferencetransformerT21

•CommutatingreactorCMR21

•FieldcircuitbreakerCBg^

•Voltageadjustrheostat(iEip(Optional)

Figure2 showstheabovecomponentsina typical

controlboxonradiatorcooledelectricgenerating

sets.

CONTROLS

Thestandardradiator-cooled,dieselpowered

generatingsetcontrolboxhasanupperanda lower

instrumentpaneldoor,Figure3.Standardcontrol

componentsincludea batterychargerateDC

ammeter,a RUN-STOP-REMOTEswitch,HEATER

switch,

OILPRESSUREgauge,WATER

TEMPERATUREgauge,anda fieldcircuitbreaker.

Optionalcontrolsthatmaybeaddedontheupper

doorpanelincludethreeACammeters,anAC

voltmeter,a runningtimeHOURmeter,a phase

selectorswitch,a 50or60Hertzfrequencymeter,line

circuitbreakers,anda voltageregulatoradjustknob.

Optionalcontrolsthatmaybeaddedonthelower

paneldoorincludea PLANTFAILEDTOSTARTfault

lamp,

a CRANKINGLIMITER,andthreefaultindica-

tionlampsforLOWOILPRESSURE,HIGHWATER

TEMPERATURE,andOVERSPEEDwiththeir

associatedpushbuttonresetswitches.

CONTROL

PANEL

COMPONENTS

ControlsandinstrumentsontheRDJFseriescontrol

panelsvaryaccordingtothecustomerspurchase

order.Thefollowingisa briefdescriptionoftypical

componentslocatedonthepanels.

Standard:

Run-Stop-RemoteSwitch:Startsandstopstheunit

locallyorfroma remotelocation.

PreheatSwitch:Controlsmanifoldheaterandglow

plugs.

BatteryChargeRateDCAmmeter:Indicatesthe

batterychargingcurrent.