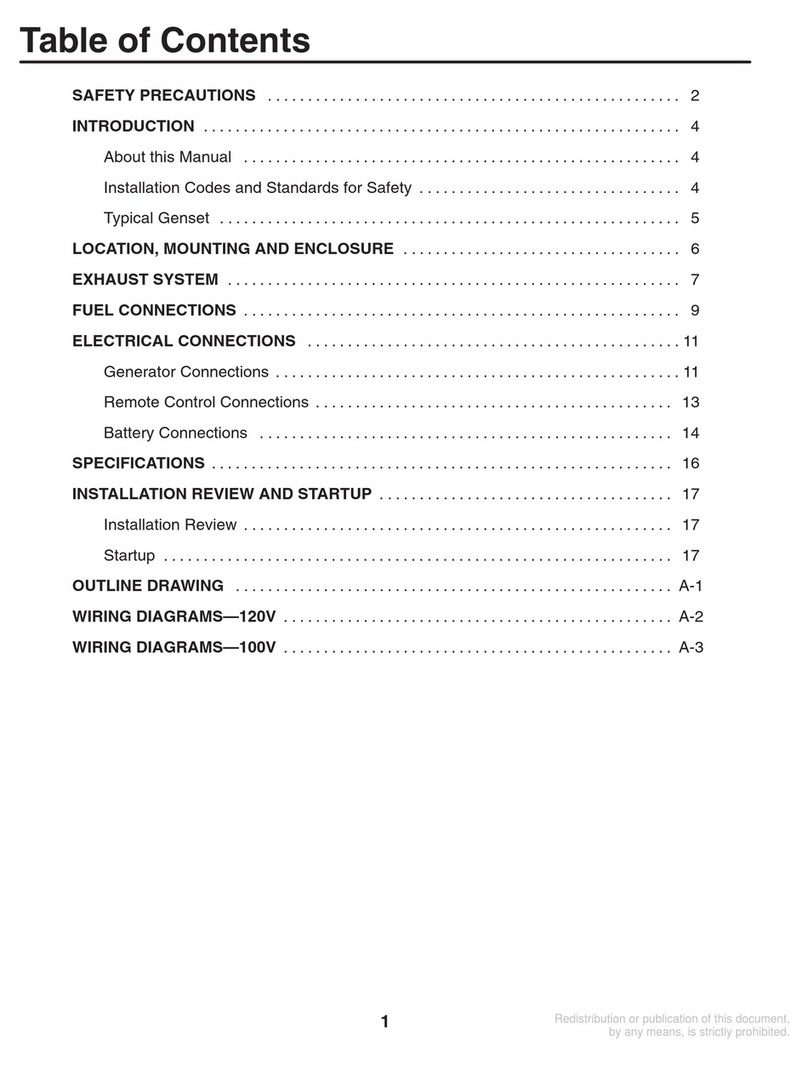

Section

2.

Specifications

GENERATOR

Type

................................................

RevolvingField,4-Pole, Self-Excited

Standby Ratings:

60 Hertz, 6.5 MCE

...........................................

6.5

kW, (6.5 kVA

@

1.0

PF)

60 Hertz, 4.5 MCE

...........................................

4.5 kW, (4.5 kVA

@

1.0

PF)

50

Hertz,

5.0

MCE

...........................................

5.0

kW,

(5.0

kVA

@

1.0 PF)

AC VoltageRegulation

.............................................................

+5%

Frequency Regulation

......................................................

.5%

(3 Hertz)

ENGINE

EngineType

............................................

Onan@MCE, 2-Cylinder Opposed

EngineSpeed (r/min)

.........................................................

I800/1500

Exhaust Outlet HoseSize

...............................................

.2.0 in. (50.8 mm)

Fuel..

..............................................................

Unleaded, 88 octane

FuelInletSize..

............................................................

.1/4-18 NPT

FuelConsumption, Average

@

FullLoad:

60 Hertz, 6.5 MCE

....................................................

1.3 gph

(5.0

Lph)

60 Hertz, 4.5 MCE

....................................................

1.6 gph

(6.1

Lph)

50

Hertz,

5.0

MCE

....................................................

1.1 gph (4.2 Lph)

FuelInletSize..

.........................................................

1/4-18 NPTF

FuelReturnOutletSize

...................................................

.1/8-27 NPT

MinimumColdCrankingAmps

@

0°F (-18°C).

......................................

360

Voltage

...........................................................................

12

Capacity, Heat ExchangerSystem..

....................................

.10 Quarts(9.4 L)

Heat Rejection:

60 Hertz

@

Load, Block

&

Exhaust Manifold..

............................

800 BTU/min

50

Hertz

@

Load, Block

&

ExhaustManifold..

............................

650 BTU/min

HeatExchangerSystem,ThermostatOpen

.........................

.2.2 gpm (8.3 L/min)

Sea Water, HeatExchangerSystem

..............................

.3.0 gpm (11.4 L/min)

SeaWater CoolingSystem

......................................

-3.0

gpm

(1

1.4 L/min)

Heat ExchangerSystem,ThermostatOpen

.........................

.2.2 gpm (8.3 L/min)

SeaWater, HeatExchangerSystem

...............................

.2.5 gpm(9.5 L/min)

SeaWater CoolingSystem

.......................................

.2.5 gpm (9.5 L/min)

SeaWater Pump

Dry

Lift, Maximum

............................................

3

ft

(0.9 m)

TotalAir Required(Generator Coolingand Combustion):

60 Hertz..

....................................................

.146 ft3/min (4.1 m3/min)

50

Hertz

....................................................

120cu. ft./min (3.4 m3/min

EngineOil Capacitywith Filter

............................................

.3Quarts

(2.8

L)

Battery Requirements:

CoolingSystem:

CoolingFlow Rate, 60 Hertz:

CoolingFlow Rate,

50

Hertz:

2-1