2Dust Cobra Owner’s Manual O.A.S. 2010

c

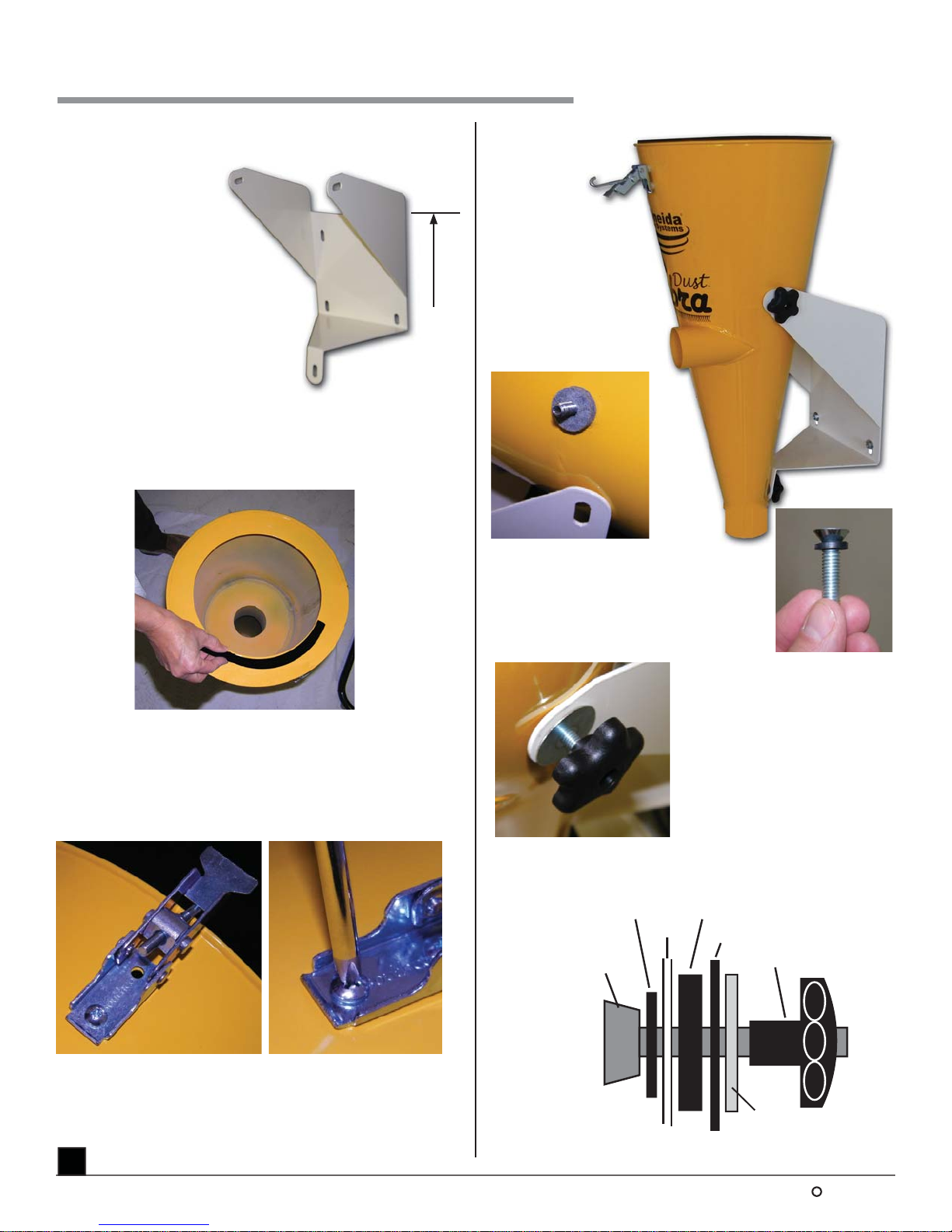

I.SystemStart-UpInformation

Caution

Read the installation and maintenance instructions as well as the recommended safety practices in

this manual before assembling and using the Dust Cobra.

This vacuum is designed for indoor / dry material pick-up applications and should not be

used outside or in wet conditions or to pick up liquids.

SafetyInstructionstobeStrictlyFollowed.

autio

The Dust Cobra is heavy! Handling and assembly should always be performed by experienced and

trained personnel who have experience with assembling equipment. In addition to the following

instructional manual, care should be taken to ensure compliance with specific safety require-

ments mandated by federal, state and local codes.

- Make sure that the voltage nameplate of the device corresponds to the voltage of your network. The plug must

be protected with a minimum of 15 amps. Important! The vacuum is supplied from the factory with a supply

cable with a grounded plug. It must only be connected to an approved grounded receptical.

- Before performing ANY maintenance work, unplug the vacuum from the outlet.

- Warning! Explosion and fire hazard! Never vacuum flammable fluids or gas, oil, alcohol, solvents, etc. Do not

operate near flammable fluids or gas. Never vacuum warm fluids or materials at more than 140 deg. F (60 Deg.

C), such as burning cigarettes, ashes, glowing coals, etc.

- Warning! Do not vacuum hazardous / carcinogenic dust unless HEPAfilter is installed.

- Do not pull the vac by the cable and do not damage the insulation on the cable. If cable is damaged, it must be

replaced immediately.

-Always keep filter cartridge clean so the vacuum operates properly.

- Components used in packaging (i.e. - plastic bags) can be dangerous. Keep away from children and animals.

- The use of this machine for anything not specified in this manual may be dangerous and must be avoided.

- The suction nozzle should be kept away from the body. Especially delicate areas such as the eyes, ears and

mouth.

- The equipment should be correctly assembled before use.

- Ensure that power receptical is correct voltage for the machine.

- Check the voltage indicated on the rating plate is the same as the supply voltage.

- Never leave the equipment switched on.

- Never carry out any maintenance on the machine without first disconnecting from the main supply. If machine

is to be left unattended or can be reached by children or others not aware about their action, the electrical sup-

ply should also be terminated.

- The vac should never be immersed in water or a pressure jet of water used for cleaning.

- Periodically examine the power cable and machine for damage. If any damage is found, contact your service

center for repair.

- Should extension cords be used, ensure that the cord rating is suitable for use with the equipment. Do not use

the extension cord coiled as this could result in a voltage drop or overheating of motor.

- If the vacuum should overturn, it is recommended that the machine should be stood up before switching off.

- Service and repairs should be carried out by qualified personnel only. Replacement parts for the machine must

be manufacturers original parts only.

- The manufacturer can not be held responsible for any damage / injury caused to persons or property because

of the incorrect use of the machine or due to procedures being used that are not specified in this instruction

manual.

- Empty dust drum frequently. Never leave flammable (including wood dust) material in vac.