3

Safety Precautions

1. Before using the appliance, read this manual thoroughly and operate under its direction.

2. “WARNING” and “ATTENTION” have the foll owing meanings in these instructions:

WARNNING! :This mark indicates procedures, which if improperly performed, might lead to the death

or serious injury of the users.

ATTENTION! :This mark indicates procedures, which if improperly performed, might possibly result in

personal injury to the user, or damage to property.

WARNNING !

zWhen install the unit, please relegate to the special arrangement maintenance center. If improper performed, it can

cause the water leakage, electric shock and fire etc. accidents.

zPlease install the unit to a steady and stable place. If the intension is inadequate, the unit will drop off and will lead

to the personal injury and death.

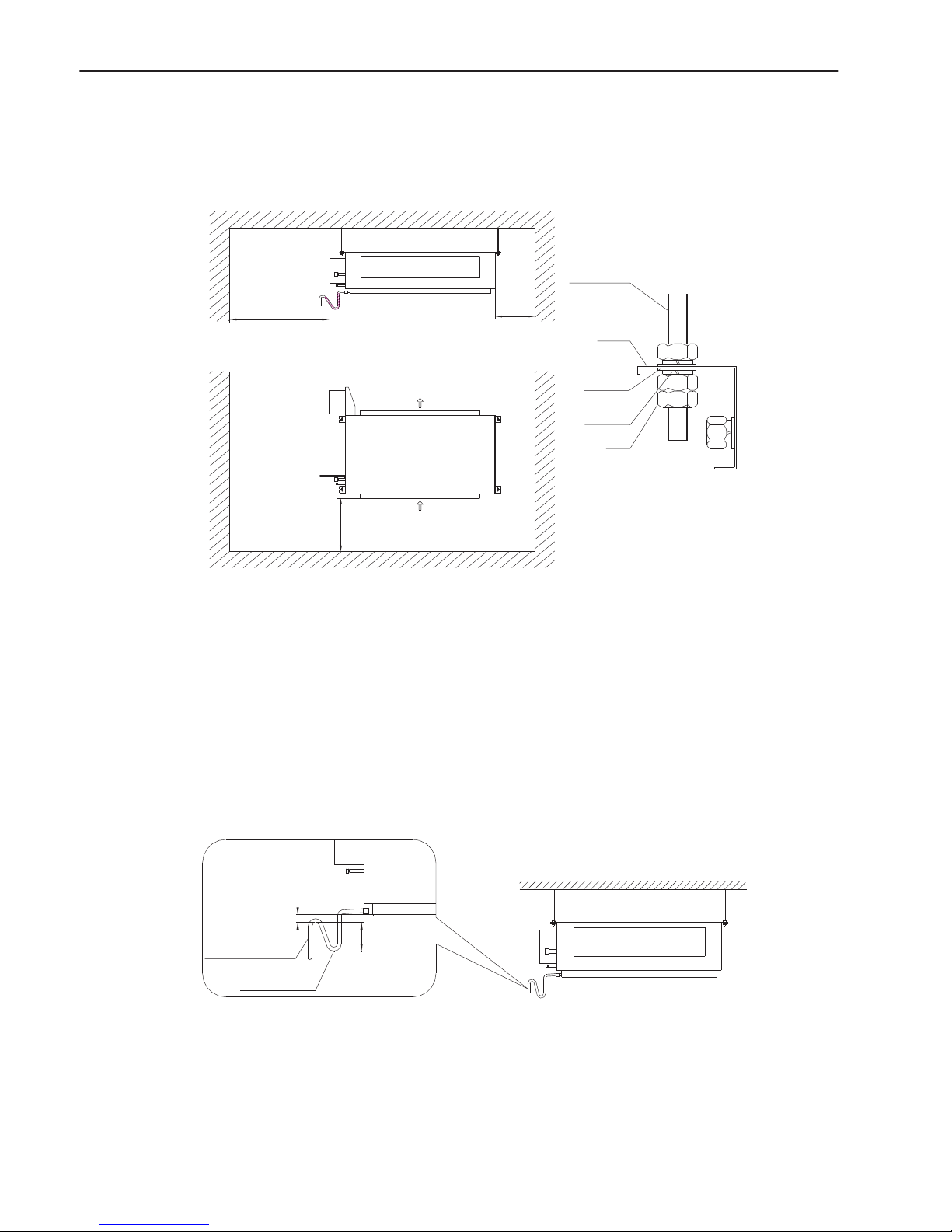

zIn order to make sure the right water drainage, the installation of drainage pipe should be according to the

installation methods of this manual, and also adopt the heat retaining measure to prevent the water condensing. If

installed improperly, it will cause water leakage and might moisten the furniture.

zDo not use or store the combustible and detonatable materials near the air conditioner.

zWhen malfunction happed (there is the burning smell etc.), please power off the general power supply of the units.

zKeep the well ventilation in order to avoid the oxygen lack.

zDo not insert hands or other objects into the inlet or outlet grille.

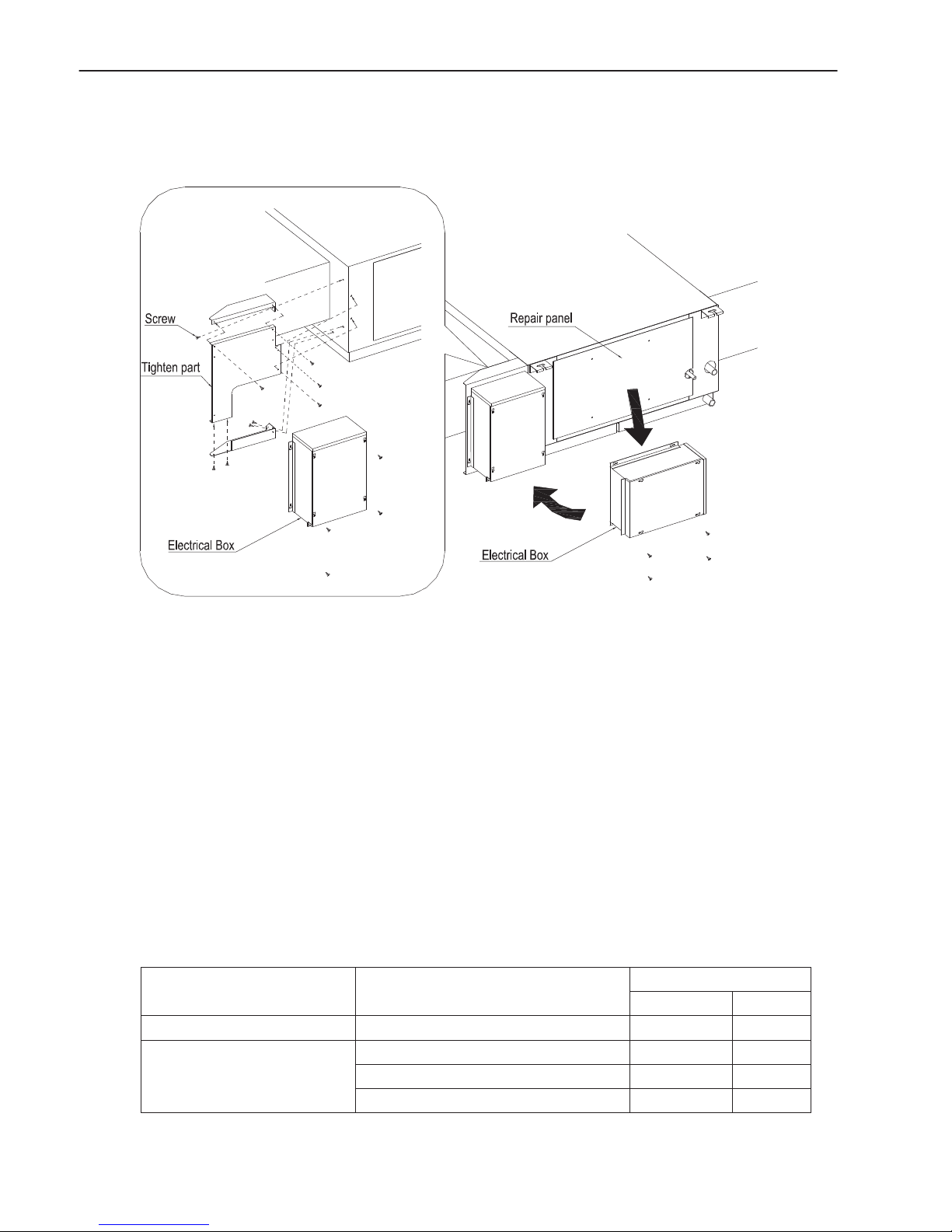

zDue to the long time use, please check the mounting frame if broken or not.

zDo not refit the unit. When need to maintenance or remove the unit, please contact with the local dealer or the

professional.

ATTENTION!:

zEnsure the power supply correspond to the nameplate and check the security of the power source before installation.

zMake sure that the wires, pipes and drain hose are properly connected before operation to avoid a fire or electric

shock.

zThe general power supply must be reliably earthed! To ensure the units are earthed availably, to avoid the electric

shock. The earth wire can’t be connected to the gas pipe, water pipe, wires of the lightning rod and telephone.

zOnce the units start, need at least more than 5 minutes running then it could be turned off.

zDon’t let children operate the units.

zDo not operate the units with wet hands.

zWhen cleaning the air conditioner or changing filters, please turn off the general power supply of the units firstly.

zSwitch off power source when the units will not be operated for a long period.

zDo not expose the units to the water place or the damp place or the corrosion environment.

zAfter installation, when electrified the electric leakage should be tested.