Printmaster-Digi60 17/04/14

IMPORTANT SAFETY INSTRUCTIONS

THIS EQUIPMENT MUST BE EARTHED TO AVOID RISK OF ELECTRIC SHOCK.

TO AVOID INJURY OR ELECTRIC SHOCK ALL PERSONNEL RESPONSIBLE FOR IN-

STALLING, OPERATING AND SERVICING THIS EQUIPMENT MUST READ AND FOLLOW

THE INSTRUCTIONS IN THIS MANUAL AND THE SAFETY INFORMATION GIVEN BELOW:

1. Read this manual fully. Follow all warnings and instructions.

2. Installation, servicing and training of users must be undertaken by suitably qualified personnel.

3. Disconnect the printer and controller from mains electricity and air supplies before cleaning or

servicing.

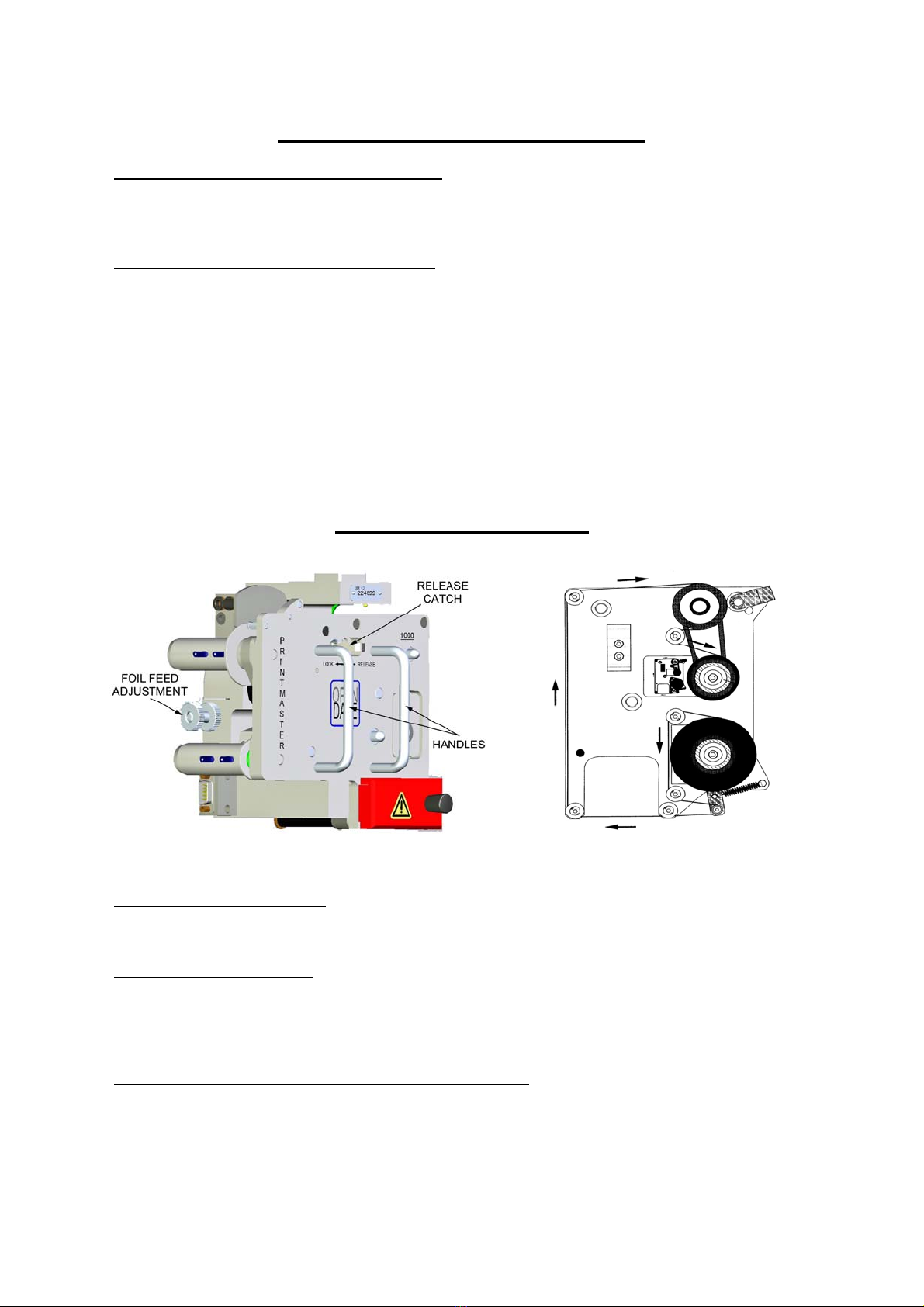

4. Never operate the printer unless it is installed in the mounting frame supplied. When installed

correctly the gap between the printer and print base should not be greater than 4mm (see

page 35).

5. Do not expose any part of the product to liquids or vapours including pressure washing or

steam cleaning.

6. Do not place the product on an unstable stand, table or machine. It may fall causing serious

damage and/or injury.

7. Never insert objects through apertures in the product as they may touch dangerous voltages

or short circuit parts that could result in fire or electric shock.

8. The product must be operated from the type of electrical supply shown on the product identifi-

cation label at the rear of the printer controller (see page 7).

9. The controller to printer cable must only be connected to an Open Date printer. It is not a sig-

nal or data cable. Connecting the cable to anything other than the specified printer may risk

electric shock or damage.

10. To ensure proper earthing the connecting cable from the controller must be fitted securely to

the printer by tightening the two retaining screws on the connector body.

11. The controller has a standard IEC C14 mains connector. A C13 (supplied) or C15 terminated

cable must be used to connect mains power.

12. The mains supply to the controller must be protected by a 5 amp fuse.

13. All cabling must be routed to avoid damage that may cause failure or risk of electric shock.

14. The product is not user serviceable. Opening or removing covers exposes persons to danger-

ous voltages, major burns and other risks. Refer all servicing to qualified personnel.

15. Do not use to use the product in areas where explosive gases or substances are present.

16. In use type-holders become hot enough to cause serious burns (<240°C). Never touch metal

parts of a type holder. Handle type-holders only by their insulated plastic handles. Never as-

sume a type holder is cold.

17. Adjust only those controls and settings covered by these instructions. Improper adjustment

may result in damage needing qualified technicians to resume normal operation.

18. Disconnect the product from the electrical and air supplies and refer to qualified personnel un-

der the following conditions:

If the cabling or connectors are damaged.

If the air pipes are damaged or leaking.

If any part of it has been exposed to liquid.

If the product does not operate normally.

If in doubt contact the manufacturer or authorised agent before proceeding with installa-

tion, operation or servicing.