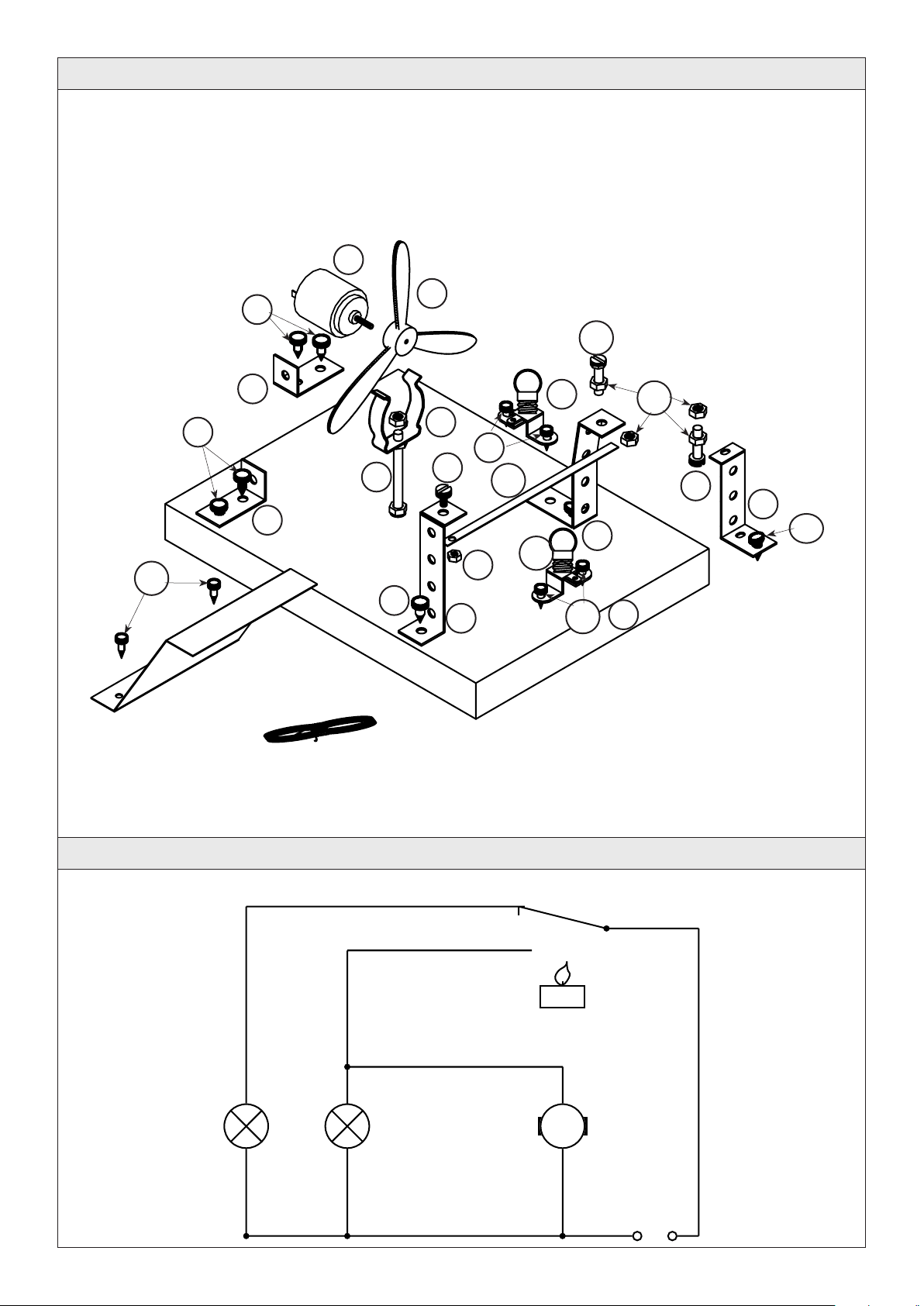

1. Product information:

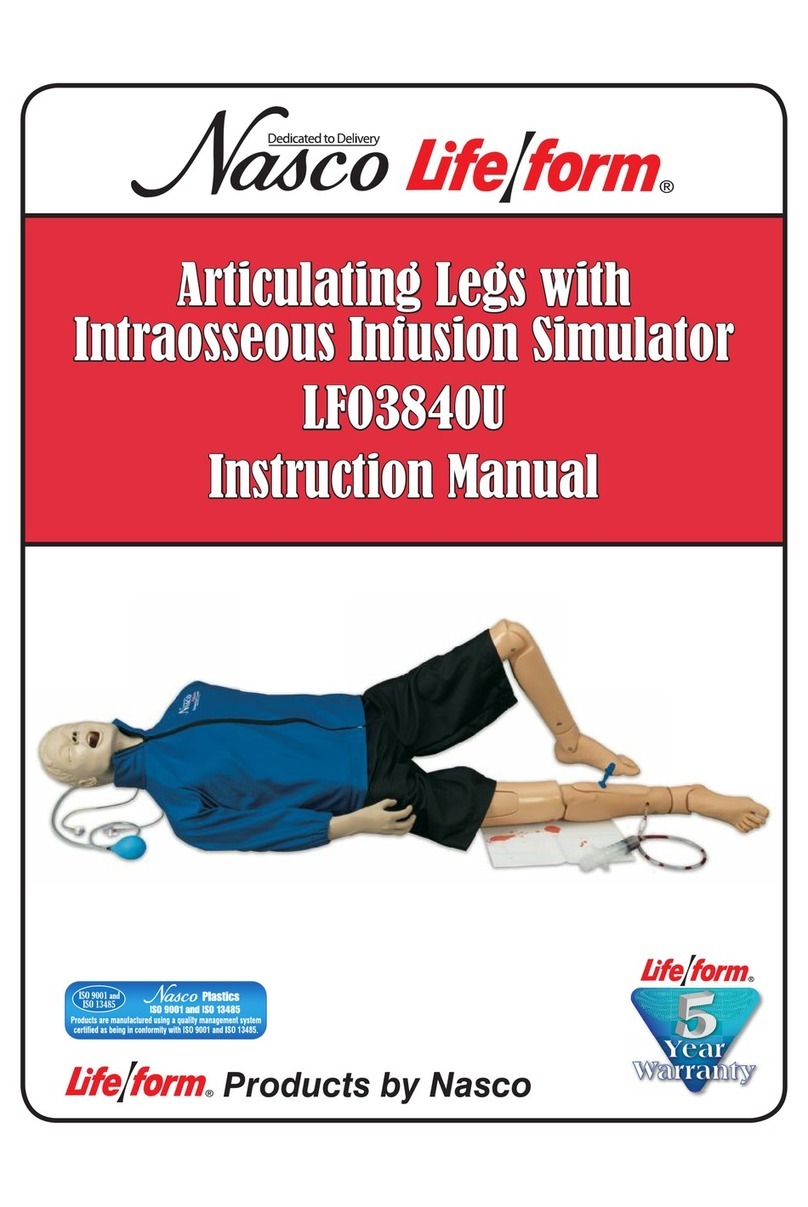

Article: electro-mechaniacal model

Use: in Design Technology Key stage 3

2. Material Information:

2.1. Material: Pine (confirous), soft wood

wood should be relativly dry before working

Working: Pine can be sawn, planed, shaped and drilled

mark out with measurements or use paper patterns

Joining: screws

Finish: wax (liquid or solid)

wood varnish (undercoat/clear)

stain (water soluable then varnish)

2.2. Material: Zinc sheet

Working: cut with metal shears / tin snips

fold using a vice

mark out by measurement or use patterns

drilling;

Joining: screws

Finish: none necessary, could be sprayed with clear varnish

2.3. Material: holed metal strip (zinc plated)

Working: cut with a Hacksaw

Bend using a vice

mark out with a scriber

Joining: use screws

Finish: no special finish necessary

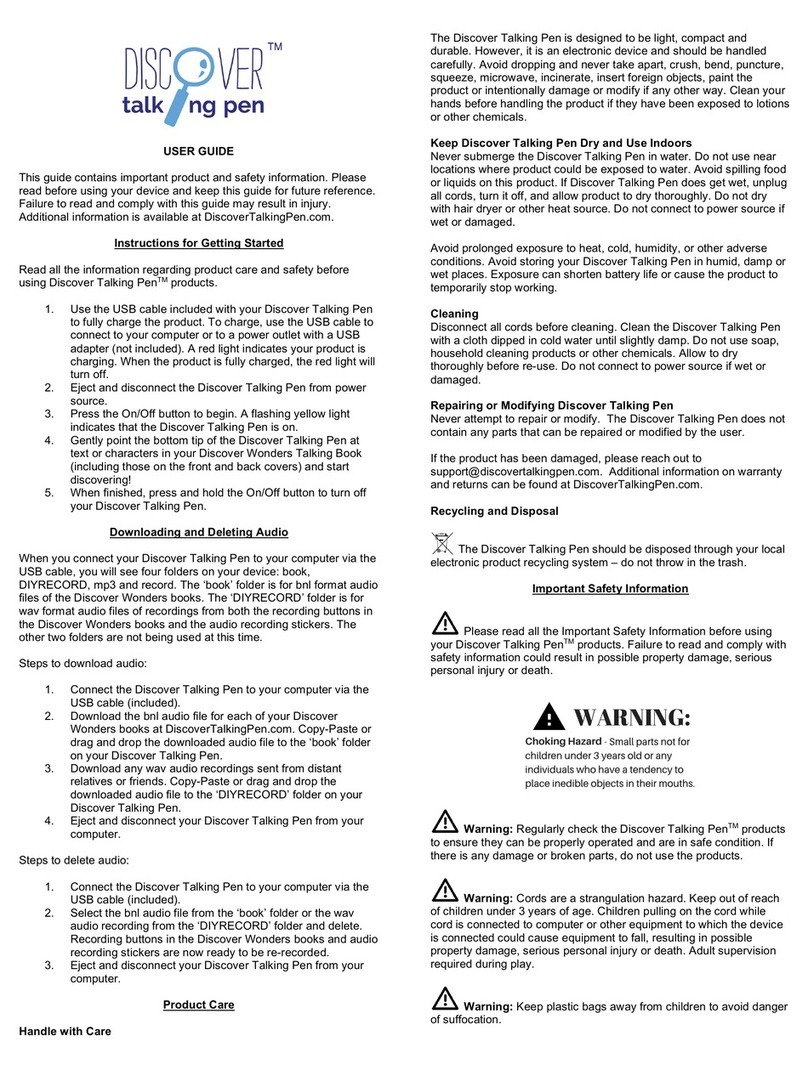

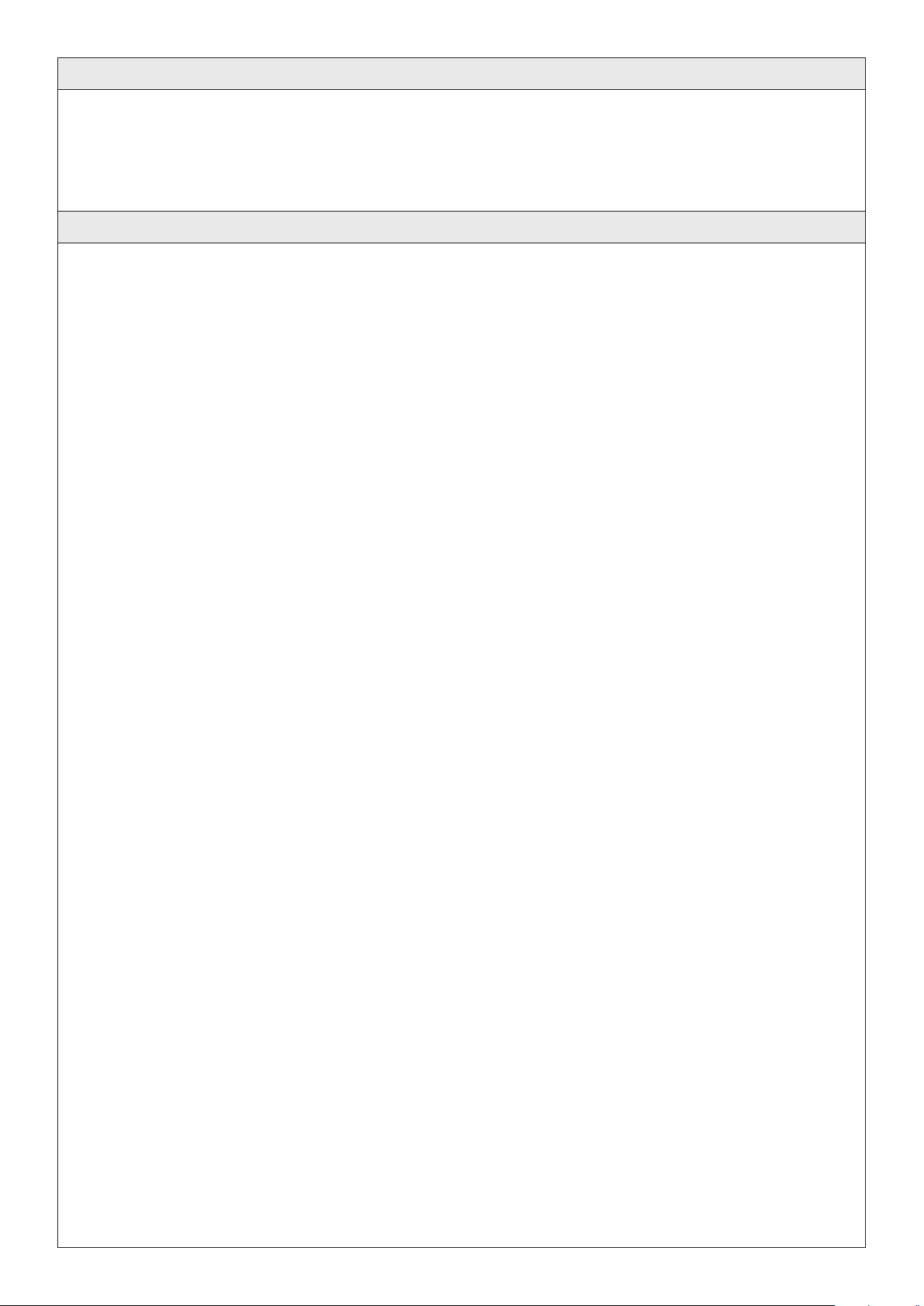

2.3. Electro components:

Bulb holder: with 2 soldering tabs

suitable for E10 bulb

Bulb: 3.5 volts, 0,2A to fit E10 holder

Insulated wire: single strip wire 0.5mm

Bi metal strip: a fusion of two different metals, with different expansions rates

Motor: DC 1.5-4.5 Volt

2E105434#1