Cleaver Scientific runVIEW Real-Time User manual

runVIEW RealTime

Horizontal System

15/11/2018 Page 1

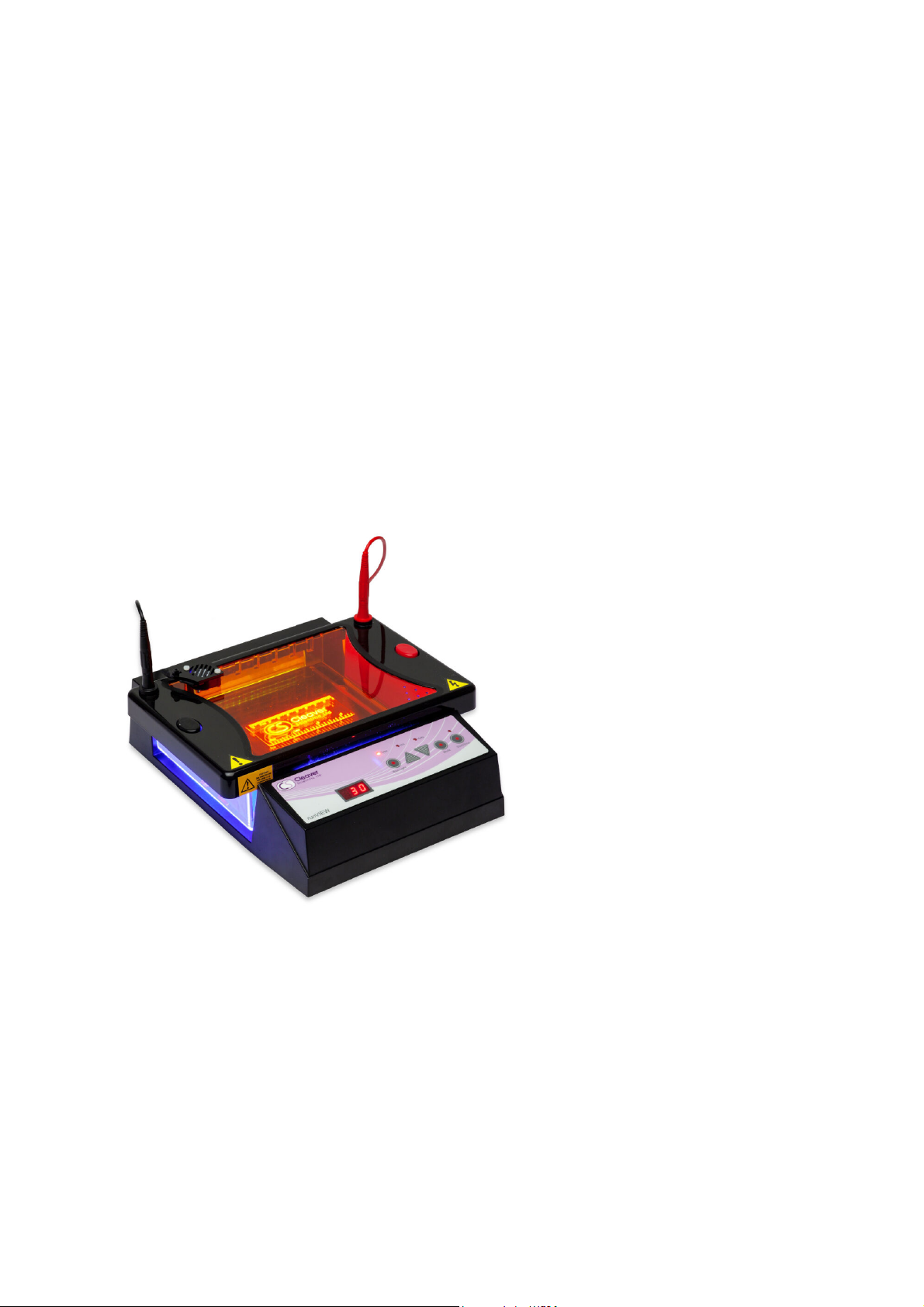

runVIEW Real-Time

Horizontal

Electrophoresis Units

Instruction Manual

Catalogue Numbers

CSL-RVMSCHOICE7

CSL-RVMSCHOICE10

CSL-RVMSCHOICE15

CSL-RVMSCHOCIETRIO

Record the following for your records:

Model _____________________

Catalogue No. _____________________

Date of Delivery _____________________

Warranty Period _____________________

Serial No. _____________________

Invoice No. _____________________

Purchase Order No. _____________________

15/11/2018 Page 2

Contents

Instruction Manual 1

Catalogue Numbers 1

Contents 2

Safety Information 3

Environmental Conditions 4

Symbols 4

Packing List 5

Specifications 6

Operating Instructions 7

Overview 7

Installation 7

Setting up the Horizontal Gel Tank 7

Fitting Electrodes 7

Fitting Loading Guides 7

Control Interface 8

Gel Preparation 9

Gel Pouring 10

Casting Dams 10

Flexicaster 10

Tape 11

Running the Gel 12

Stain Compatibility 13

Solutions 14

References 14

Troubleshooting 15

Gel Issues 15

runVIEW Issues 16

Care and Maintenance 17

Cleaning Horizontal Units 17

RNAse Decontamination 17

Ordering information 18

Comb options 18

Related Products 20

Warranty 21

15/11/2018 Page 3

Safety Information

The runVIEW real-time horizontal DNA electrophoresis system has been

thoroughly tested and found to comply within the limits of CE regulation. It

has been manufactured using the latest technology and does not require

maintenance. When used correctly this unit poses no particular health risk,

although it can deliver dangerous voltage levels if used incorrectly.

Accordingly, this power supply must only be operated by fully qualified

personnel adhering to the guidelines laid out within this instruction manual.

Although this power supply is equipped with all necessary safety features

against abuse and accidental failure, caution should always be exercised

when working with high voltage equipment. Any individual intending to use

this instrument should read the entire manual thoroughly before operation.

1. Read the instruction manual thoroughly before use.

2. Never touch the power outlets with any conductive object (e.g. naked

metal wire) other than properly insulated power supply cables.

3. Do not spill liquid or insert metal objects inside the power supply.

4. Never block the ventilation holes or place the unit in any enclosure

unless there is adequate ventilation; never expose the power supply to

a direct heat source.

5. Never touch any part of the power supply assembly (i.e. power supply,

cables or electrophoresis tank) before switching OFF the power supply.

6. Never manipulate with wet hands.

7. Do not connect to ground any of the power outputs or the buffer within

the electrophoresis tank; the power outputs should be only connected

to an insulated electrophoresis tank equipped with a safety cover.

8. Do not connect any power supplies in series or in parallel.

9. Never open the back plate nor remove the cover, otherwise an

electric shock may result. Repairs should only be made by the

manufacturer or a service technician authorised by the manufacturer.

10. Never use this power supply if the safety cover is not in position

correctly.

11. Do not use the unit if there is any sign of damage to the external tank or

cover. Contact the manufacturer or supplier immediately to replace or

repair any damaged parts.

15/11/2018 Page 4

12. Never use the power supply in the presence of flammable or

combustible material as fire or explosion may result.

13. Ensure that the power supply is only connected to an earthed power

line. Do not cut and splice the power line. When removing the power

cord from the wall, unplug it by holding the plug attachment and not

by pulling the cord. Do not hold the plug with wet hands or gloves.

Environmental Conditions

This unit may only be installed and operated only under the following

environmental conditions:

1. For indoor use only

2. Relative humidity: ≤95%

3. Atmospheric pressure: 75 kPa – 106 kPa

4. Altitude: ≤2000 metres

5. Operating temperature: ambient to 40°C

6. Pollution degree: 2

7. Mains supply voltage fluctuations up to ±10% of the normal voltage

This apparatus is rated POLLUTION DEGREE 2 in accordance with IEC 664.

POLLUTION DEGREE 2, states that: “Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused by

condensation must be expected”.

Symbols

The symbols used on this unit are explained below. Indicates the

potential for electric shock. Consult the manual to avoid possible

personal injury or instrument damage.

Indicates disposal instruction.

DO NOT throw this unit into a municipal trash bin when this unit has

reached the end of its lifetime. To ensure utmost protection of the

global environment and to minimise pollution, please recycle this unit.

15/11/2018 Page 5

Packing List

All Models Include:

Base Station & Lid CSL-RVBSBVLID

Tank MS15TANK

Cable CSL-CAB

Combs 1 x MS15-4/16MC-3

1 x MS15-20/28MC-3

2 x MS15-4/16MC-1

4 x MS15-20/28MC-1

Specific models include:

CSL-RVMSCHOICE7 CSL-RVMSCHOICE10 CSL-RVMSCHOICE15 CSL-

RVMSCHOICETRIO

Tray MS15-UV7 MS15-UV10 MS15-UV15 MS15-UV7, MS15-

UV10, MS15-UV15

Casting

Dams

MS15-UVDAM MS15-UVDAM MS15-UVDAM 3 x MS15-UVDAM

Packing List Checked by: ________________________

Date: ________________________

The packing lists should be referred to as soon as the units are received to

ensure that all components have been included. The unit should be checked

for damage when received.

Cleaver Scientific is liable for all missing or damaged parts / accessories within

7 days after customers have received this instrument package. Please contact

Cleaver Scientific immediately regarding this issue. If no response within such

period is received from the customer, Cleaver Scientific will no longer be liable

for replacement/damaged parts.

Please contact your supplier if there are any problems or missing items.

15/11/2018 Page 6

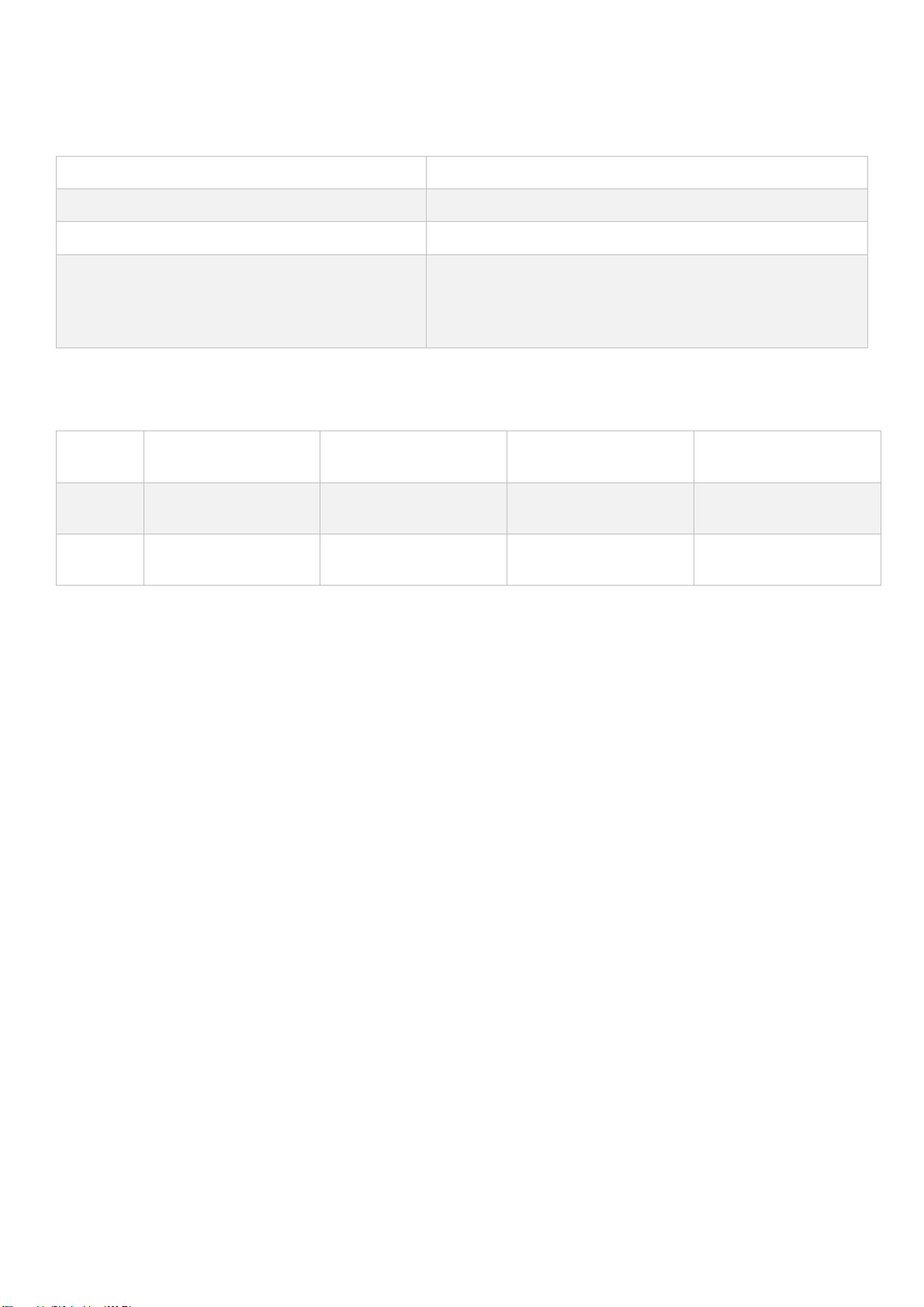

Specifications

runVIEW Viewing Dock

Blue Light

Wavelength

470nm Timer 1-999 minutes with alarm

Voltage/

Resolution

25-150V / 1V Safety Device No load detection

Current/ Resolution 300mA / 1mA Operating

Temperature

Ambient to 40C

Power 30 W Dimensions 293 x 220 x 80 mm

Operating Mode Constant Voltage or

Current

Rated Voltage 100-240V, 50/60Hz

runVIEW Gel System

Gel Dimensions

(W X L)

15 X 7, 15 x 10 &

15 X 15cm

bluVIEW

Lid Design

Orange spectral emission filter

with condensation-free

viewing pane (Safe dyes –

e.g. runSAFE); Red version for

EtBr

Unit dimensions

(W X D X H)

26.5 X 17.5 X 9cm Combs - 1 x MS15-4/16MC-3

- 1x MS15-20/28MC-3

- 2x MS15-4/16MC-1

- 4x MS15-20/28MC-1

Buffer Volume 500ml Comb Thickness 1 & 3mm

15/11/2018 Page 7

Operating Instructions

Overview

runVIEW is an innovative system designed for real-time size fractionation and

recovery of nucleic acids. runVIEW can maximise the efficiency of DNA

recovery from EtBr and SYBR stained gels by minimising the number of steps

involved in post-electrophoretic purification. runVIEW consists of a multiSUB™

MSCHOICE system with bluVIEW lid, containing a spectral emission filter and

extractor fan within its viewing pane, and a base unit with integrated power

supply and blue LED gel illuminator.

Installation

Place the runVIEW on a sturdy and level, dry surface. Plug the power cord

into the back of the unit and mains power. The system is now ready for use.

Setting up the Horizontal Gel Tank

Fitting Electrodes

Note the position of the lid on the unit. This shows the correct polarity

and the correct orientation of the cables, black is negative and red

positive.

Remove the lid from the unit. Note if the lid is not removed, fitting the

cables may result in un-tightening of the gold plug and damage to the

electrode.

Screw the cables into the tapped holes as fully as possible so that there

is no gap between the lid and the leading edge of the cable fitting.

Refit the lid.

Fitting Loading Guides

These can be fitted to enhance visibility of the wells if desired. They can be

fitted to the white vinyl platform sheet or to the unit itself.

1. Seat the tray in the unit and note the position of the comb grooves. The

samples run black to red, but the trays can be used frontward or

backwards so ensure that the comb grooves closest to the black

electrode are marked.

2. Remove the tray.

15/11/2018 Page 8

3. Peel the back off the loading guide and carefully apply the loading

guide directly to the gel platform.

The unit is now ready to be used.

Control Interface

There are five buttons and four LED indicators on the faceplate.

Each LED indicates the activation status or mode of operation of the unit.

1. To select Voltage, Current or Time

2. To switch blue light ON or OFF

3. Increase selected parameter

4. Decrease selected parameter

5. Start / stop the program

To set the required voltage, current and time, use the mode button to

navigate between these parameters. The active parameter will be indicated

by a lit LED.

Use the up and down arrows to set the desired parameters.

Press the Start / stop button to start the electrophoresis run.

To activate the blue light for 10 seconds, press the blue light button once. To

permanently activate the blue light, hold the Blue light button for 3 seconds.

15/11/2018 Page 9

Gel Preparation

The Table below shows the volume of agarose solution required to make the

desired agarose gel for each unit tray size. For a standard 0.7% agarose gel,

add 0.7 grams of agarose to 100 ml of 1x TAE or TBE solution. The same 1X

solution should be used in the tank buffer solution.

Tray 15 x 7 cm 15 x 10 cm 15 x 15 cm

Gel volume for a 5mm thick gel 52.5 mL 75 mL 112.5 mL

1. Add the agarose powder to a conical flask.

2. Add the appropriate amount of 1x TAE or TBE solution from the table

above. To prevent evaporation during the dissolving steps below, the

conical flask should be covered with parafilm.

3. Dissolve the agarose powder by heating the agarose either on a

magnetic hot plate with stirring bar or in a microwave oven. If using the

microwave method, the microwave should be set at around a 400 watt

or medium setting and the flask swirled every minute. The solution

should be heated until all crystals are dissolved. This is best viewed

against a light background. Crystals appear as translucent crystals.

These will interfere with sample migration if not completely dissolved.

The gel must be cooled to between 50°C and 60°C degrees before pouring.

For Real-Time visualisation, mix a compatible DNA stain such as Ethidium

Bromide with your agarose gel in the required proportion. This allows DNA to

be visualised during the run.

Alternatively, runSAFE DNA stain can be used as the sample loading buffer to

enable real-time visualisation.

15/11/2018 Page 10

Gel Pouring

The multiSUB®range of units allows three different methods of gel casting:

1. Casting Dams

2. Flexicaster

3. Traditional Tape

Casting Dams

1. To fit the casting dams, place one casting dam on the bench with the

groove facing upwards (1). Push the edge of the tray down firmly into

the groove (2). Repeat this for the other side (3). The dams should be

fitted so that there is no gap between the sides of the tray and the

groove in the dams. This will ensure that there is no possibility of gel

leakage.

2. Place the comb(s) in the grooves. Each tray has more than one comb

grove so that multiple combs can be used. Using multiple combs

increases sample number available per gel but decreases run length

and care must be taken to ensure that samples from the first wells do

not migrate into the lanes of the second comb wells.

3. Pour in the agarose carefully so as not to generate bubbles. Any

bubbles that do occur can be smoothed to the edge of the gel and

dispersed using a pipette tip.

4. Allow the agarose to set, ensuring that the gel remains undisturbed.

5. Carefully remove the gel casting gates and comb and transfer the gel

including tray to the main tank.

Flexicaster

1. Level the Flexicaster base by adjusting the feet so that the bubble is

exactly central.

(1) (2) (3)

15/11/2018 Page 11

2. Insert the desired length tray into the Flexicaster such that one end of

the tray is pushed up and seals against the silicone mat of the

permanent end of the Flexicaster.

3. Position the movable end of the Flexicaster so that the silicone mat is

pushed against the other end of the tray.

4. Turn the cam so that the silicone mat tightly seals against the side of the

tray. Pour in the agarose carefully so as not to generate bubbles. Any

bubbles that do occur can be smoothed to the edge of the gel and

dispersed using a pipette tip.

5. Allow the agarose to set, ensuring that the gel remains undisturbed.

6. Carefully remove the gel casting gates and comb and transfer the gel

including tray to the main tank.

Tape

1. Autoclave or plastic backed general tape should be used. A length

5cm longer than the width of each end of the tray should be cut. One

length should be placed over one end of the tray and stuck m1cm in

from the tray edge. This should then be folded, and the edges sealed

securely. Repeat for the other end and place onto a level surface for

gel pouring.

2. Place the comb(s) in the grooves. Each tray has more than one comb

grove so that multiple combs can be used. Using multiple combs

increases sample number available per gel but decreases run length

MS7-FC and MS20-FC Flexicasters

15/11/2018 Page 12

and care must be taken to ensure that samples from the first wells do

not migrate into the lanes of the second comb wells.

3. Pour in the agarose carefully so as not to generate bubbles. Any

bubbles that do occur can be smoothed to the edge of the gel and

dispersed using a pipette tip.

4. Allow the agarose to set, ensuring that the gel remains undisturbed.

5. Carefully remove the gel casting gates and comb and transfer the gel

including tray to the main tank.

Running the Gel

1. Mix the sample to be loaded with sample buffer or runSAFE 6X DNA

stain for real-time visualisation.

2. Fill the unit with buffer until the gel is just flooded with buffer. This will give

the fastest resolution times. For enhanced quality of resolution of

sample, fill the unit to 5mm above the gel.

3. Load the samples into the wells using pipettes. Multi-channel pipettes

can be used for loading samples with MC compatible combs, see

listing in accessories for identification of these.

4. Carefully place the lid on the tank and connect to the Base Station.

Connect the Lid Fan to the runVIEW Base Station.

5. Typically, gels are run at between 90 and 150 volts. However, maximum

voltages are indicated on the serial badge of each unit. It should be

noted that higher voltages generally give faster but poorer quality

sample resolution.

To operate under constant voltage or constant current modes, adjust the

other parameter to the maximum value. For example, to operate under

constant voltage, adjust the current to the maximum output of 300mA

before running the power supply with the voltage set at the desired output

setting.

15/11/2018 Page 13

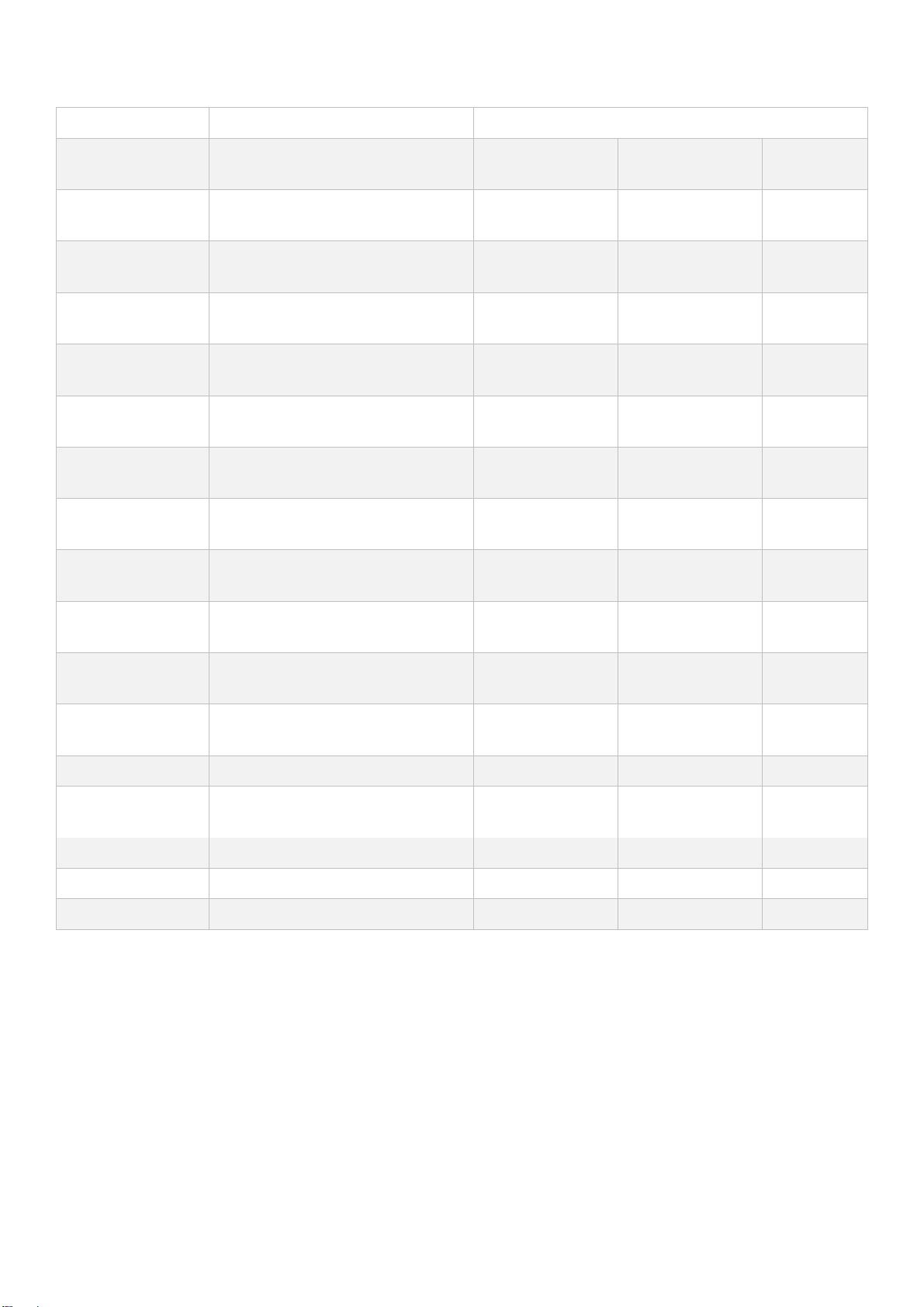

Stain Compatibility

Staining Method

Nucleic Acid

Stain

Relative Performance

Between Stains

Gel Pre-

Staining

Gel Post-

Staining

Sample

Staining

SYBR® Green I

(DNA)

Higher Intensity Bands

Observed

SYBR® Green II

(RNA)

Higher Intensity Bands

Observed

SYBR® Gold Higher Intensity Bands

Observed

Midori Green

Direct

Higher Intensity Bands

Observed

Hydra Green™

Safe DNA Dye

Higher Intensity Bands

Observed

HD Green™

DNA Stain

Higher Intensity Bands

Observed

runSAFE Higher Intensity Bands

Observed

SafeView DNA

Stain

Compatible -Visible Bands

Observed

SYBR® Safe Compatible -Visible Bands

Observed

Midori Green Compatible -Visible Bands

Observed

Midori Green

Advanced

Compatible -Visible Bands

Observed

EtBr Faint Bands Observed*

SERVA DNA

Stain Clear G

Faint Bands Observed*

HealthView™Faint Bands Observed*

GelGreen™Faint Bands Observed*

GelRed™Faint Bands Observed*

*Compared to the same gel on a UV Transilluminator

15/11/2018 Page 14

Solutions

0.5M EDTA stock (500mL) dissolve in 400 ml distilled water:

93.05g EDTA disodium salt

Fill to 500 ml litre final volume with distilled water

50X TAE stock (1L) dissolve in 750 ml distilled water:

242 g tris base (FW = 121)

57.1 ml glacial acetic acid

100 ml 0.5 M EDTA (pH 8.0).

Fill to 1 litre final volume with distilled water

10X TBE stock (1L) dissolve in 750 ml distilled water:

108 g tris base (FW = 121)

55 g boric acid (FW = 61.8)

40 ml 0.5 M EDTA (pH 8.0)

Fill to 1 litre final volume with distilled water

Loading Dye

10x sample buffer stock consists of 50% glycerol, 0.25% bromophenol blue,

and 0.25% xylene cyanole FF in 1x TAE buffer. Only 1–10 ml of the 10x loading

dye should be prepared.

Ethidium Bromide Solution

Add 10 mg of Ethidium Bromide to 1 ml distilled water.

References

1. Sambrook, Fritsch, and Maniatis, Molecular Cloning A Laboratory

Manual, Second Edition, Cold Spring Harbor Laboratory Press, 1989.

2. Current Protocols in Molecular Biology, Greene Publishing Associates

and Wiley-Interscience, 1989.

15/11/2018 Page 15

Troubleshooting

Many operating problems may be solved by reading and following the

instructions in this manual accordingly. Some suggestions for troubleshooting

are given below. If these suggestions fail to resolve the problem, contact

support@cleaverscientific.com or the Cleaver Scientific distributor in your

region for assistance. If troubleshooting is required, please include a full

description of the problem.

Gel Issues

Problem Cause Solution

Bands sharp but not enough

bands seen

Gel agarose percentage too

high

Incomplete digestion

Decrease agarose percentage.

Review enzyme activity, digest

further.

Band smearing and streaking

Agarose has improper

endosmosis

Salt concentration in sample too

high

Excessive power and heating

Sample spilled out of well

Incomplete digestion, nuclease

contamination, bad enzyme

Sample wells cast through the

gel. Sample leaks along bottom

of running surface

Consult Cleaver Scientific about

agarose.

Reduce salt concentration to

≤0.1M.

Reduce voltage. See

electrophoresis instructions.

Apply sample carefully. Increase

gel thickness for large sample

volumes. Adjust comb height.

Heat sample. Review enzyme

activity. Digest sample further.

Comb should be placed to 1 to 2

mm above the base of the

running surface.

Curved line or distortion of bands Bubbles in sample wells Remove bubbles prior to

electrophoresis.

Curved bands, smiles Sample overload Reduce load.

Differential relative mobilities

Sample spilled out of wells

Unit not levelled

Samples should have proper

density. Apply carefully.

Level unit. Use a steady work

bench.

Gels crack

Too high voltage gradient,

especially with low melting

temperature agarose or low gel

strength gels

Reduce voltage. Run gel at lower

temperature.

High MW bands sharp; low MW

bands smeared Gel agarose percentage too low Increase agarose percentage.

Switch to polyacrylamide.

Ragged bands

Sample density incorrect

Sample well deformed

See sample application

instructions.

Carefully remove comb,

especially from soft gels. Make

sure gel has solidified.

15/11/2018 Page 16

Excessive power or heating

Cooling soft gels aids in comb

removal.

Reduce voltage. See

electrophoresis instructions.

Slanted lanes (bands) Gel not fully solidified

Comb warped or at an angle

Gel to solidify for at least 30-

45min.

Check alignment of comb.

runVIEW Issues

Problem Cause Solution

No Display / lights No AC power. Check if the power supply is unplugged, or if

the AC power source is a problem.

AC power cord is not

connected.

Check AC power cord connections at both

ends. Use the correct cords.

The fuse has blown. Replace the fuse

Operation stops Electrophoresis leads are

not connected to the

power supply or the

electrophoresis unit; or

the circuit is broken in

the electrophoresis

system.

Check the connections to the power supply

and within electrophoresis system to make

sure the connection is intact; check the

electrodes to make sure they are intact.

Close the circuit by reconnecting the cables.

Press START/STOP to restart the run.

High resistance due to

tape left on a pre-cast

gel, incorrect buffer

concentration, or

insufficient buffer

volumes in the

electrophoresis system.

Make sure that the tape is removed from the

pre-cast gel, that the buffers are prepared

correctly, and the recommended volume of

buffer is added to the electrophoresis unit

and is covering the gel.

Error message

Over voltage (170V

safety limit reached or

exceeded).

Press START/STOP button to clear the error

message. Contact Cleaver Scientific’s service

department if the problem persists.

Message

No load is detected. (1) Check the connections.

(2) Check the buffer condition / buffer

Level.

Alarm message

Maximum power output

reached (30 W).

Warning message for reference.

15/11/2018 Page 17

Care and Maintenance

Each runVIEW system uses all solid-state components and should require no

maintenance or recalibration under normal use. If the unit is to be returned

Cleaver Scientific distributor.

Cleaning Horizontal Units

Units are best cleaned using warm water and a mild detergent. Water at

temperatures above 60°C can cause damage to the unit and components.

The tank should be thoroughly rinsed with warm water or distilled water to

prevent build-up of salts, but care should be taken not to damage the

enclosed electrode and vigorous cleaning is not necessary or advised.

Air drying is preferably before use.

The units should only be cleaned with the following:

Warm water with a mild concentration of soap or other mild detergent.

Compatible detergents include dishwashing liquid, Hexane and Aliphatic

hydrocarbons

The units should not be left to in detergents for more than 30 minutes.

The units should never come into contact with the following cleaning agents,

these will cause irreversible and accumulative damage:

Acetone, Phenol, Chloroform, Carbon tetrachloride, Methanol, Ethanol,

Isopropyl alcohol, Alkalis.

RNAse Decontamination

This can be performed using the following protocol:

Clean the units with a mild detergent as described above.

Wash with 3% hydrogen peroxide (H2O2) for 10 minutes.

Rinsed with 0.1% DEPC-(diethyl pyro carbonate) treated distilled water,

Caution: DEPC is a suspected carcinogen. Always take the necessary

precautions when using.

RNaseZAP™(Ambion) can also be used. Please consult the instructions for

use with acrylic gel tanks.

15/11/2018 Page 18

Ordering information

Ordering Information

CSL-RVMSCHOICE7 runVIEW system complete with 15 x 7cm gel tray.

CSL-RVMSCHOICE10 runVIEW system complete with 15 x 10cm gel tray.

CSL-RVMSCHOICE15 runVIEW system complete with 15 x 15cm gel tray.

CSL-RVMSCHOICETRIO runVIEW system complete with 15 x 7, 15 x 10 and 15 x 15cm gel trays.

CSL-RVBSBVLID runVIEW base station & bluVIEW lid.

Comb options

Catalogue No. Tank Thickness Sample Number Tooth Width (mm) Volume (ul)

MS15-1-0.75 Choice 0.75 1 110 371

MS15-2-0.75 Choice 0.75 2 50 169

MS15-4-0.75 Choice 0.75 4 27 91

MS15-10-0.75 Choice 0.75 10 10 34

MS15-10MC-0.75 Choice 0.75 10 6.5 22

MS15-12-0.75 Choice 0.75 12 9 30

MS15-14MC-0.75 Choice 0.75 14 6.5 22

MS15-16-0.75 Choice 0.75 16 6 20

MS15-20-0.75 Choice 0.75 20 4.75 16

MS15-28MC-0.75 Choice 0.75 28 2.5 8

MS15-35-0.75 Choice 0.75 35 2.2 7

MS15-1-1 Choice 1 1 110 495

MS15-2-1 Choice 1 2 50 225

MS15-4-1 Choice 1 4 27 122

MS15-10-1 Choice 1 10 10 45

MS15-10MC-1 Choice 1 10 6.5 29

MS15-12-1 Choice 1 12 9 41

MS15-14MC-1 Choice 1 14 6.5 29

MS15-16-1 Choice 1 16 6 27

MS15-20-1 Choice 1 20 4.75 21

MS15-28MC-1 Choice 1 28 2.5 11

MS15-35-1 Choice 1 35 2.2 10

MS15-1-1.5 Choice 1.5 1 110 743

MS15-2-1.5 Choice 1.5 2 50 338

MS15-4-1.5 Choice 1.5 4 27 182

MS15-10-1.5 Choice 1.5 10 10 68

MS15-10MC-1.5 Choice 1.5 10 6.5 44

MS15-12-1.5 Choice 1.5 12 9 61

MS15-14MC-1.5 Choice 1.5 14 6.5 44

MS15-16-1.5 Choice 1.5 16 6 41

MS15-20-1.5 Choice 1.5 20 4.75 32

This manual suits for next models

4

Table of contents

Popular Educational Equipment manuals by other brands

MOKIDA

MOKIDA ZM2605201LOK-000-000 user manual

Hope Education

Hope Education 5MP USB visualiser manual

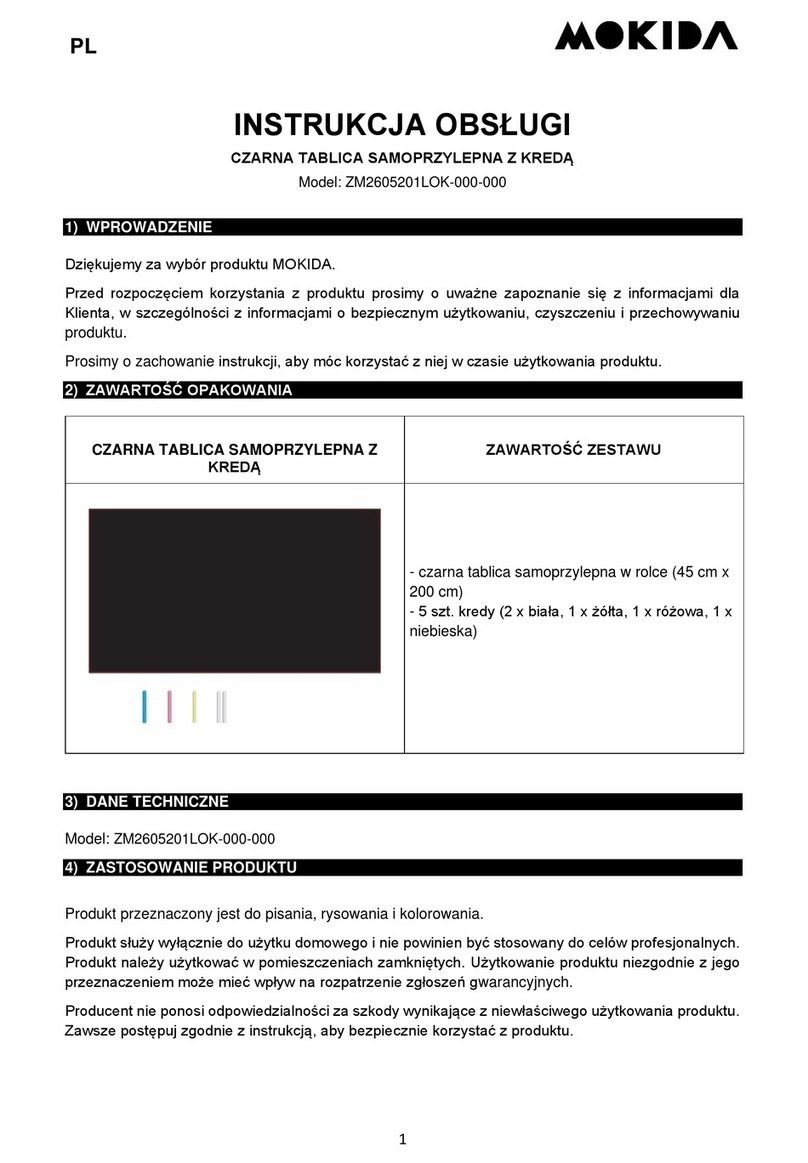

OPEN DOOR DESIGN

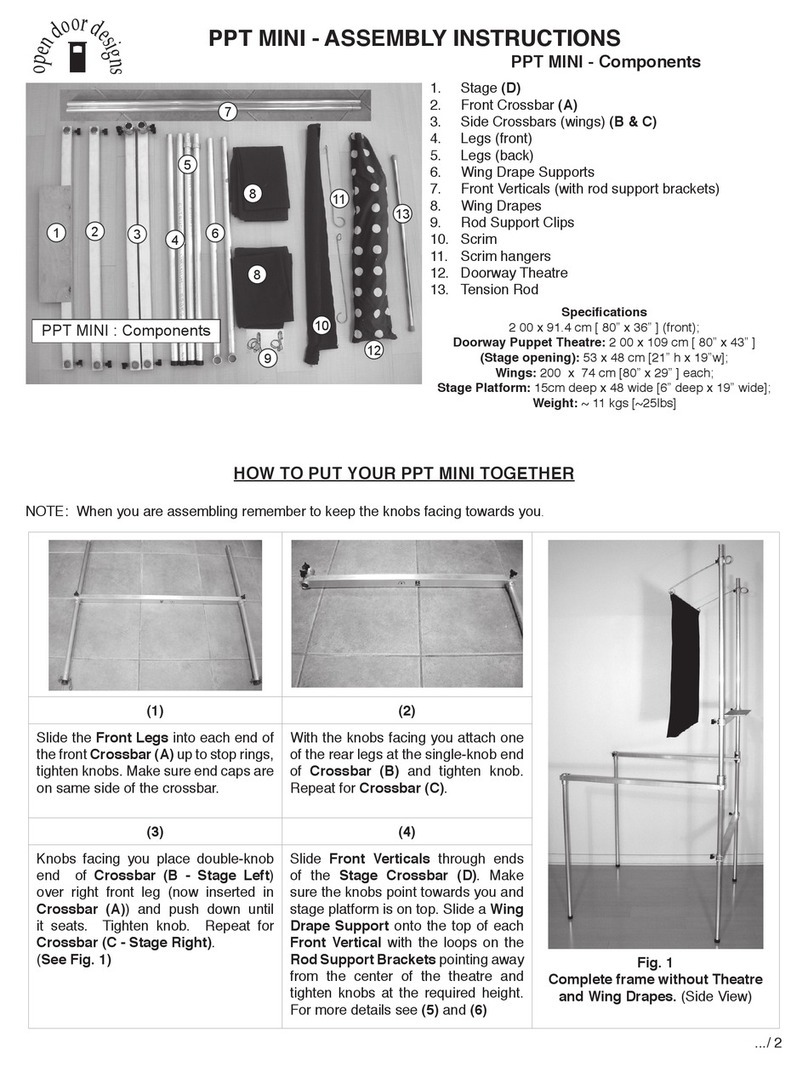

OPEN DOOR DESIGN PPT MINI Assembly instructions

Touchboards

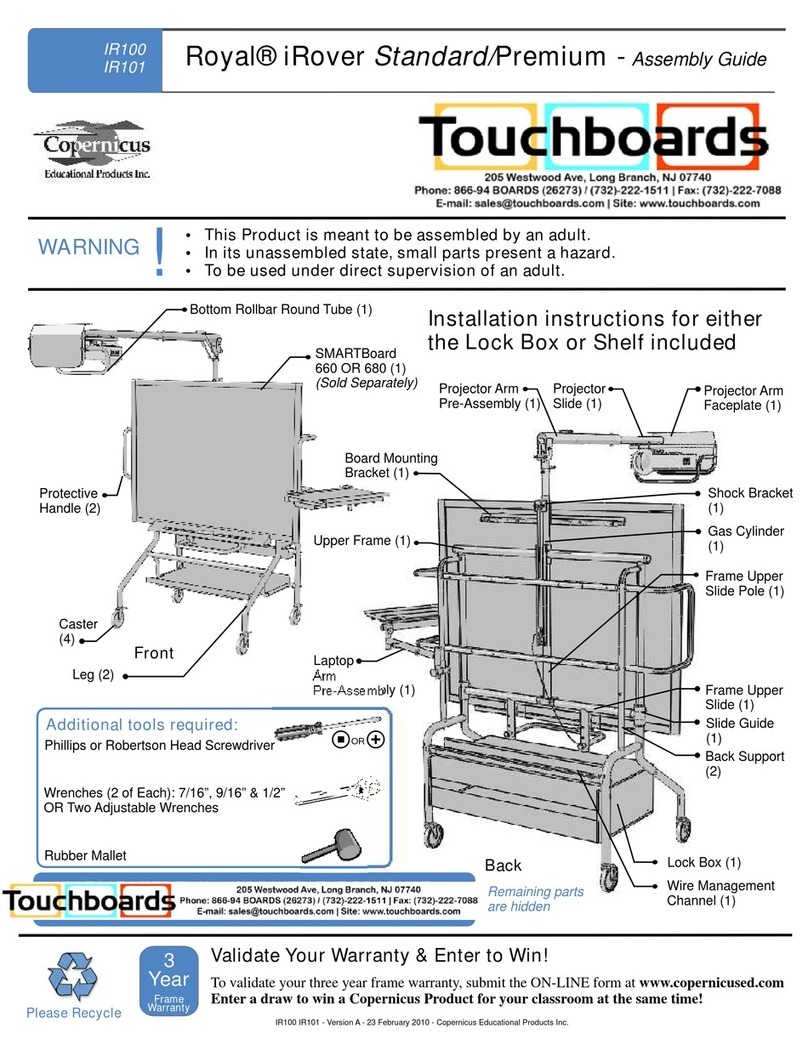

Touchboards Royal iRover Standard Assembly guide

Nasco

Nasco CRiSis LF03957 instruction manual

Horizon Educational

Horizon Educational FCJJ-44 Assembly guide