Simulaids RANDY 9000 User manual

RANDY 9000

Instruction and Care Manual

Product Instructions

Thank you for purchasing this Simulaids Training Device. The purpose of this document is to familiarize you with

the assembly process and to explain the use and care of the product. This product, Randy 9000, is intended to be

used in water, land or air rescue evolutions, particularly in exercises that are too dangerous to be dependent upon

volunteers. The product is warranted against defects in materials or workmanship for a period of three years.

However, this warranty coverage does not include damage due to abuse, misuse, or alteration of the product.

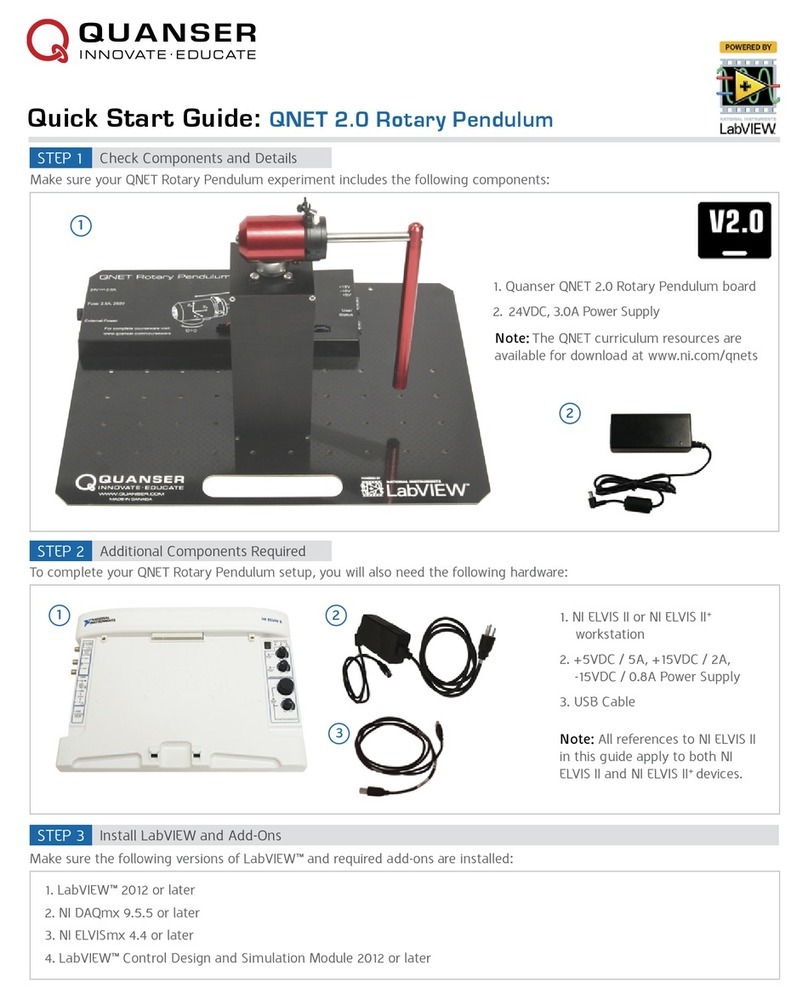

You will receive this product in various pieces, the majority of which are “halves.” These halves are the front and

back portion of each body part. For instance, the lower leg is made up of the front half with the foot and the back

half with the heel. Within each of the ball joints reside a ball joint stop to limit the range of motion, making three

plastic parts to each joint and the associated nut/bolt/washer combination. Put the ball joint assemblies together

first. Then begin your assembly process, lay out each of the parts in their relative position so that you can visualize

the various parts. There are four 4” ball joints for the knees and elbows, two 5” ball joints for the shoulders, two 6”

ball joints for the hips plus the one 8” ball joint in the mid torso. The 8” ball joint utilizes the single joint stop that

has a larger bolt hole diameter than the rest.

The above photo shows one leg assembly front and back halves with hardware.

You will also find a package of hardware. The stainless steel nuts and bolts hold together the halves of the lower

leg, upper leg, pelvis, torso, lower arm, upper arm, etc. The 6 Acorn Nuts are for use in the hand area where the

threads for the common bolts may need a smooth covering. There are also longer bolts for installation in the ball

joints. The sized and shouldered bolts furnished with this product prevent you from over tightening the bolts,

thereby cracking the plastic. If you lose any of these bolts, we strongly recommended that you contact Simulaids to

obtain replacement parts shown in the chart below. Also within the packaged contents are the tapered, hole-

stoppers: 2 small, green ones for the waist ball joint seals and 25 larger, black ones for the rest of the body parts.

Each body part half has a hole in which you may place weight material for custom weighting your Randy 9000. It is

important that you insert all of the stoppers in their perspective holes in each half, even if you are not filling both

halves. This not only preserves the stoppers for later use, but also allows the stopper on one side to hold and seal

the stopper on the other as the parts are bolted together.

Hardware found in the carton of the Randy 9000

If all of the parts are filled with water, the manikin will weigh 170 pounds. If all of the body parts are filled with dry

sand, the manikin will weigh 250 pounds. It is recommended that if you want to make a lighter manikin that you do

so by completely filling one half of an extremity so that the weight doesn’t shift during the movement of the

manikin and disrupt any balance achieved by the rescuers. Another way to make a lighter manikin is to only fill one

half of any extremity. For instance, if you fill one half of the right thigh and no other parts of the right leg, the

manikin will be lighter than if you also fill one half of the lower leg.

Once you have determined the appropriate parts to fill, the substance you want to use to fill them, and the

number of parts to fill, and have accomplished the filling process, start the assembly of the manikin by laying the

back pieces of the manikin in their relative position. Then place the ball joints in their respective locations

throughout the body. Take note that the knee joints and the elbow joints have limited range of motion in one

direction. It is possible to put these joints in backward, or 180 degrees out of alignment. It will be easy to see in the

lower leg since the foot will be backward. If that’s the case, simply turn the ball joint over in the lower leg so that

the stop points the toes the other way. The same holds true with the elbow joints and the lower arm positioning.

Or, in other words, you may end up with an arm that only bends backwards. Simply change its position to the

other side of the manikin so that the forearm bends forward, or reverse the positioning of the ball joint.

You’ll note that the ball joint ends are held firmly in place by the addition of the front half of the body parts. During

the placement of the front halves, you may choose to insert the hardware and start securing the bolts. Do not

tighten all of the bolts until the manikin is fully assembled in case you have not anticipated the need to either fill or

drain one of the parts. Once you are satisfied that the manikin is weighted and constructed appropriately, secure

the bolts down to their tightest torque. Mentioned earlier in these instructions is the fact that these shoulder bolts

Component

Description

Qty

per

PP0011

Bolt 18-8 Stainless Oal 6"

2

PP0012

Bolt 18-8 Stainless Oal 8"

1

PP0024

Plug Round Tapered 1" Height

1

PP0029

Stop 2" Diameter X 1.90" Long

8

PP0036

Acorn Nut High Crown 10-24 Ss

1

PP0054

Nutdriver 1/2" Hex Dia 3/8"

1

PP0055

Nutdriver 7/16 Hex Dia 3/8"

1

PP0056

Nutdriver 3/8" Hex Dia 3/8"

2

PP0085

Locknut 1/4-20 18-8ss Serrated

1

PP0096

Carton Paperboard 3x2x 5 1/4

2

PP0114

Plug 5/8" Large End Id Push-in

2

PP0116

Stop 2" With 3/8" Hole

1

PP0156

Bolt 3/8 Hex Hd Indented 70pk

1

PP0160

Washer Flat 18-8 Ss 1/4 Screw

1

PP0162

Nut Flange Serrated Hex 18-8ss

1

PP0163

Bolt 18-8 Ss Oal 4" Pkg Of 4

1

PP1133

Carton 8 X 6 X 6 Ect #32

1

PP5541

Bolt 18-8 Stainless Oal 5"

1

are sized to hold the parts together without stressing the plastic, so the only damage you can do if you over tighten

the bolts is destroying the nut or bolt.

If, in the future, you want to transport the product but wish to lighten your load, you may simply remove the pelvis

section and have the upper and lower pieces of the manikin to move. This will save time and effort and prevent

having to unload each of the pieces every time you move it.

CLEANING AND STORAGE

When water is used for weighting the manikin, add two drops of commercial laundry bleach to each part that

contains water (increase this to 5 drops in the larger parts like the chest). This will kill all bacteria in the water and

effectively prevent having to empty the water under normal conditions.

Do not leave the water in the manikin if there is any possibility that the water will freeze. Some freezing prevention

can be ensured if you include the proper amount of recreational vehicle non-potable water antifreeze in the parts.

The Randy 9000 is made from polyethylene, so none of these chemicals will damage the product. If you empty the

anti-freeze liquid out of the manikin, be sure to dispose of the fluid properly.

Normal surface cleaning of the manikin can be done with any household cleanser.

Use of this product in very warm climates is approved, but it is not fire proof; the warmer the weather, the more

pliable the plastic. Extremely cold temperatures puts plastic at risk of cracking, so handle the manikin gently, as

you would a patient, in near freezing conditions. However, under most human tolerance temperatures, the

product will remain useable.

Shipping Size:

Carton size: 54 x 25 x 11 inches

Shipping weight: 90 lbs

Randy 9000 Fully Assembled

Randy 9000 Replacement Hardware

Plastic part

#

Description

Bolt Item

Package

9023

Shoulder joint

PP5541

9018

Hip Joint

PP0011

9015

Waist Joint

PP0012

9012

Knee and Elbow

joint

PP5540

All other body parts

PP5495

Table of contents

Other Simulaids Educational Equipment manuals

Popular Educational Equipment manuals by other brands

Quanser

Quanser 6 DOF Hexapod Laboratory guide

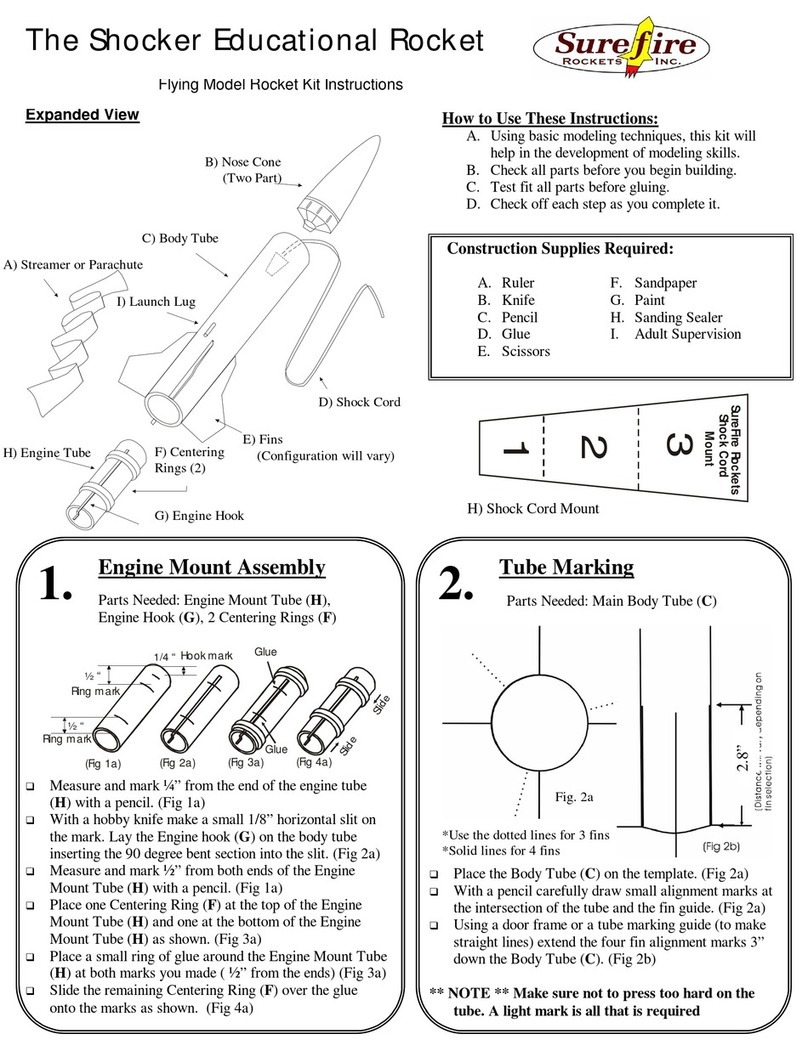

Surefire

Surefire Flying Model Rocket Kit How to use

ACROME

ACROME myCONTROL STEWART PRO user manual

SmartMan

SmartMan Baby Manikin manual

Nasco

Nasco Life/form LF03840U instruction manual

Pitsco Education

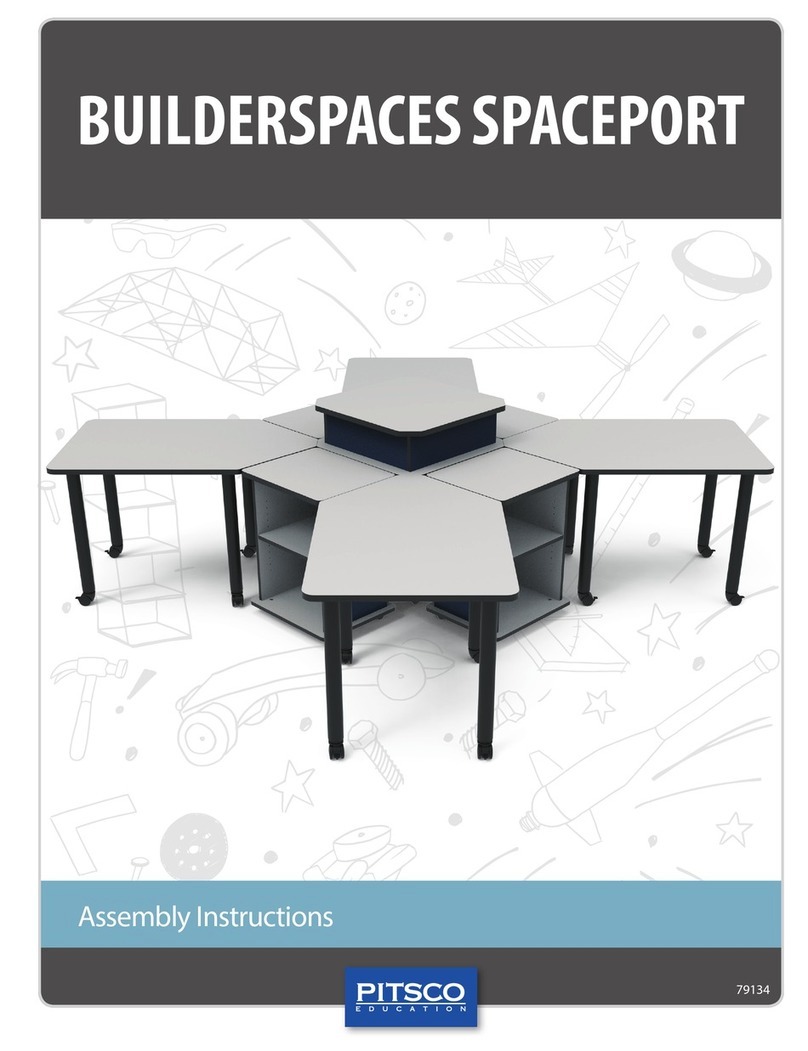

Pitsco Education BUILDERSPACES SPACEPORT Assembly instructions