- 7 -

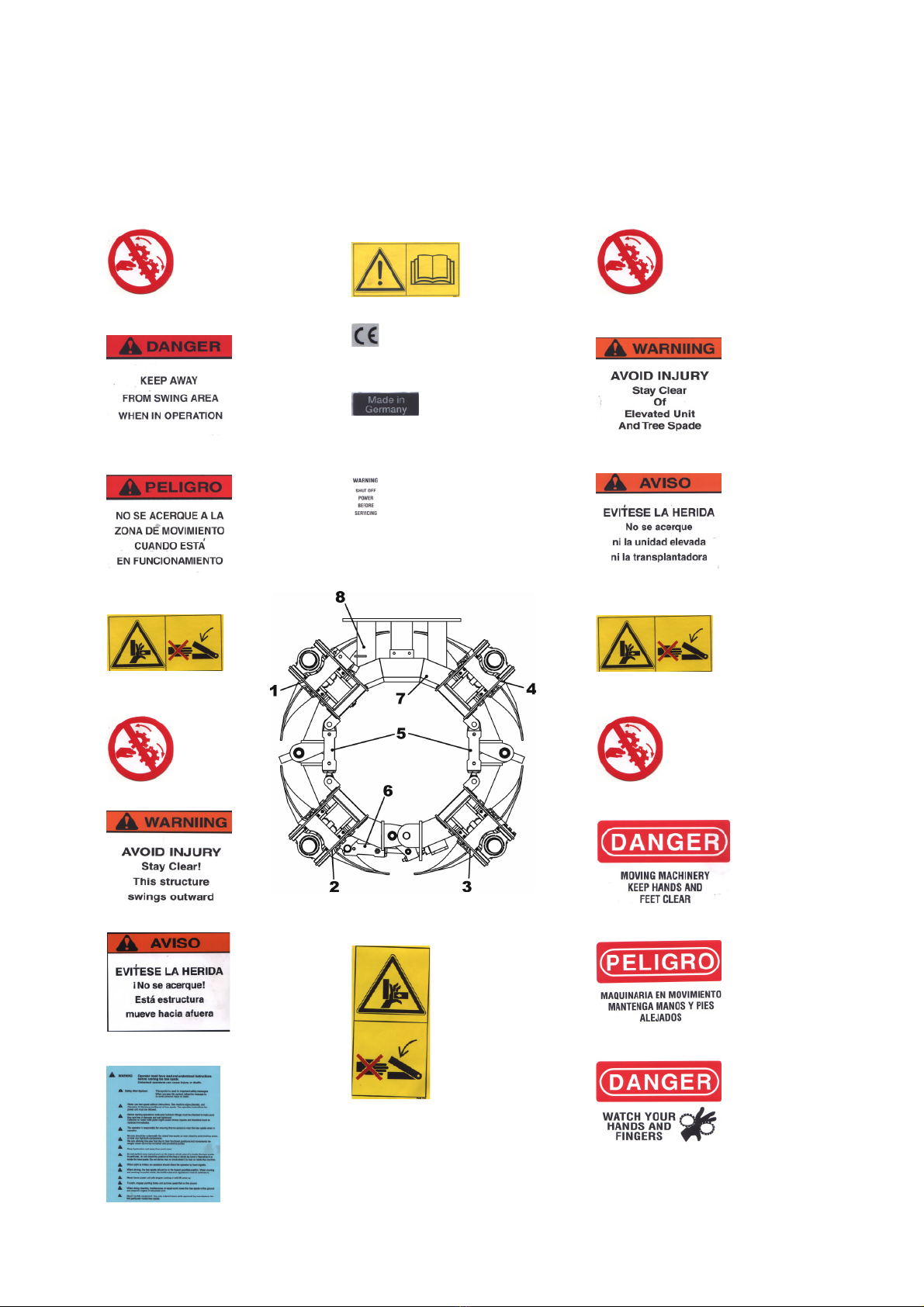

By means of control valve (2) lift arm ▼"down" the digging head is lowered fully until resting on the

ground. With control valve (3), digging head "rotate" ▲"in", ▼"out" the digging head frame is aligned

horizontally. Check again if the tree is in the center of the frame and correct, if necessary.

3.1.5 Now digging can commence:

control valve (1), rotary switch No. 3, alternatively push button S1-S4,

blades ▼"down".

For clean digging and to get the full depth of the root ball, the digging head must be kept

steady. This is achieved by working the blades crosswise, i.e. first two blades opposite to

each other are pressed for about 1/3 into the ground. Then the other two blades are pressed

into the ground. This crosswise digging is repeated until all four blades are completely in the

ground.

However, this digging depth of 1/3 is a rule of thumb only because the successive digging

process depends on the soil.

As soon as the digging head frame begins to lift, digging must be carried on with the other

two opposite blades.

3.1.6 Once all four blades have been fully pressed into the ground, the root ball pads are gently

pressed onto the root ball:

control valve (1), rotary switch No. 4, root ball presses ▼"down"

The root ball presses serve to hold the root ball together and keep it in shape.

3.1.7 Now the root ball together with the tree can be lifted out of the ground. First the rear

stabilizers must be extended. This is done as described under item 3.1.1.

3.1.8 The tree is in a vertical position and it is lifted with control valve

(2

). When the digging head is

above the base frame, it is rotated in until the tree is in a horizontal position:

control valve (3), digging head ▲"rotate in"

Lower lift arm until the digging head rests on the base frame:

control valve (2), lift arm ▼"down"

Now digging head and tree are in transport position.

3.1.9 Before the truck moves, both rear stabilizers must be retracted:

control valve (4) and (5) ▲"up"

IMPORTANT: When moving and working on public roads, the traffic rules

and regulations must be adhered to.!