®

OPTIMUM QUALITY MAXIMUM RELIABILITYTM

76

CP316S2-I OPERATING INSTRUCTIONS

Importa t Operati g I structio s

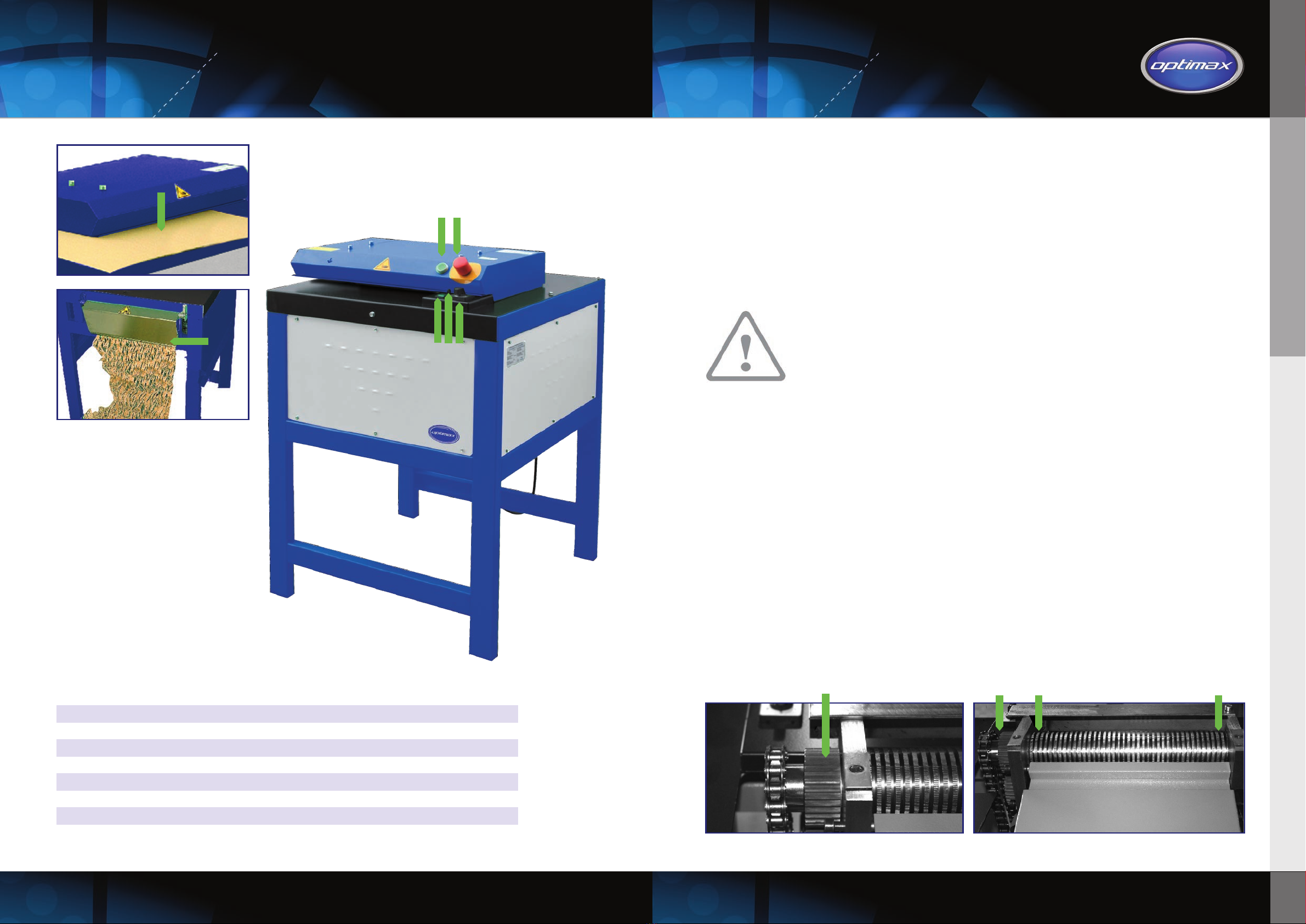

> This machine is suitable for processing paper materials exceeding

60gsm and corrugated cardboard up to 10mm thick.

> Use of unsuitable materials may result in operator in ury, damage to

the machine and accelerated wear or damage of the cutting blades.

> If processing waste packaging material, always ensure that no hard

ob ects are concealed in folds or carton flaps.

> If processing cartons containing staples, where possible feed the

cartons through the machine so that the stapled areas fall outside

the feed path and discard these sections.

> Individual staples cannot cause damage to the cutting mechanism,

but risk damage to packaged contents or in ury if left in packaging

material

Safety

Operating Instructions should be readily available and must be complied with at all times.

Care must be taken to prevent long hair, loose clothing and ewellery from becoming

caught in the mechanism.

Defects and malfunctions which endanger the safety of the employees must be repaired

repaired and the machine must be put out of operation until these hazards have been

eliminated.

Mai te a ce a d service

The machine must be thoroughly checked at least once a year by an authorised person.

All safety features must be checked every 2-3 months to confirm they have not been

removed or disabled and to identify signs of wear or malfunction.

The cutting mechanism must be regularly checked and kept clean (see instructions on

page 3 of this manual).

The cutting rollers must be lubricated periodically, by spraying light oil such as WD40 onto

them through the feed inlet whilst the machine is running.

Operatio

Connect to mains. Turn rotary knob at the front (5) to the right; when the green light shows (3)

the machine is operational.

Feed cardboard material into the feed aperture (1) until the mechanism grips it. Large pieces of

cardboard may require additional support, but hands must be kept well clear of the feed aperture

at all times.

To turn the machine off under normal operating conditions, switch the rotary knob (5) to

the middle position. In an emergency, press the emergency stop button (7). To resume

operation, the emergency stop button must be rotated anti-clockwise to release it.

If the thickness of cardboard fed into the machine is too thick and it ams, switch the rotary knob

(5) to the middle position to stop the machine, then to the red postion to reverse the feed and

remove the cardboard from the machine.

If the machine overheats, the thermal overload switch (4) will activate and automatically stop

the machine. If this occurs, pause the machine for a few minutes then depress the thermal

overload switch and resume operation.

Paddi g flap

The flap attached at the rear of the machine converts the processed cardboard into

high-bulk void fill.

If protective matting is required, disconnect the two springs situated either side of the flap (2).

Cautio – ensure that processed cardboard can freely exit the outlet channel at all times.