Optoma HD67 User manual

Other Optoma Projector manuals

Optoma

Optoma HD66 User manual

Optoma

Optoma TW865-NL User manual

Optoma

Optoma EH200st User manual

Optoma

Optoma HD27e User manual

Optoma

Optoma Optoma ThemeScene H77 User manual

Optoma

Optoma X304M User manual

Optoma

Optoma EX521 User manual

Optoma

Optoma Optoma TX612 User manual

Optoma

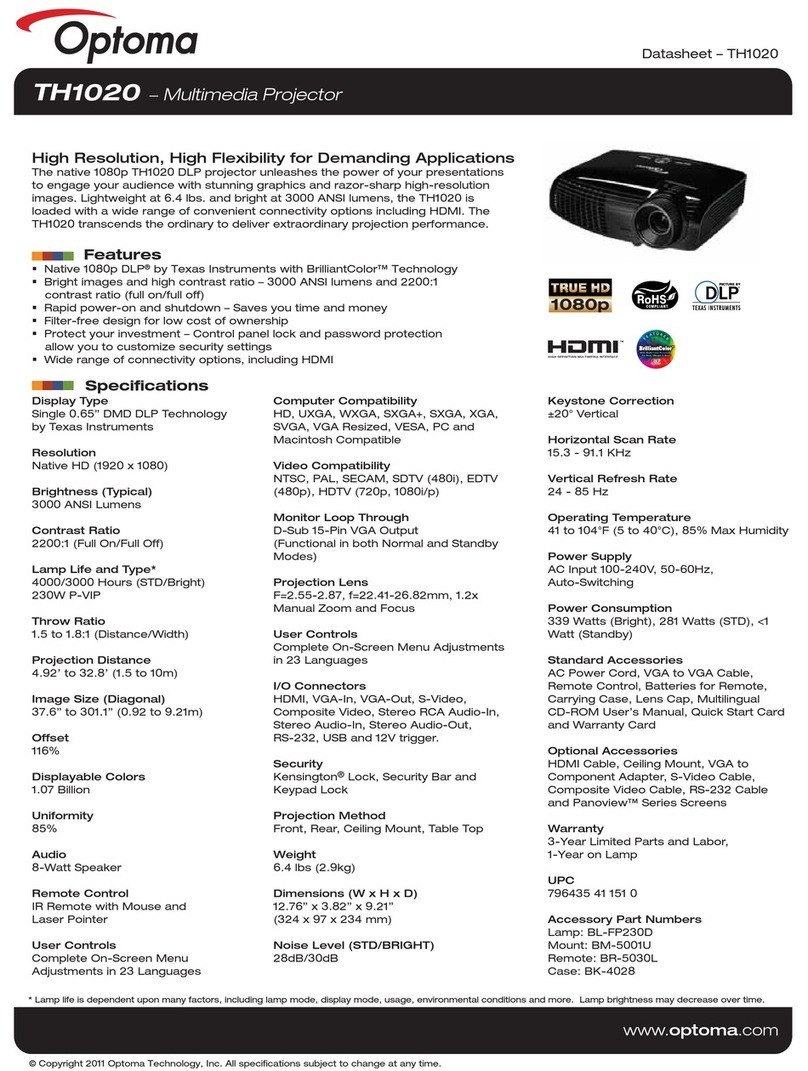

Optoma TH1020 User manual

Optoma

Optoma PT100 User manual

Optoma

Optoma EP540 User manual

Optoma

Optoma ML550 User manual

Optoma

Optoma Pico PK201 User manual

Optoma

Optoma TW330 User manual

Optoma

Optoma TS721 User manual

Optoma

Optoma TW610 User manual

Optoma

Optoma ZW340e User manual

Optoma

Optoma HD70 User manual

Optoma

Optoma ZU920TST User manual

Optoma

Optoma HD33 User manual