4. Insert welding rod and melt. Attention: Welding rod gets hot

5. Remove remaining plastic in hole with supplied cleaning stick

Naturally, the repaired part has to be finish sanded. For further processing of bare

plastics: see corresponding chapter. Painting can be done after welding (according to

the plastic type (where necessary, after primer treatment). Spray-on textured or matt

finishes can be used to simulate the original surface and colour.

6.3. Crack and hole repair

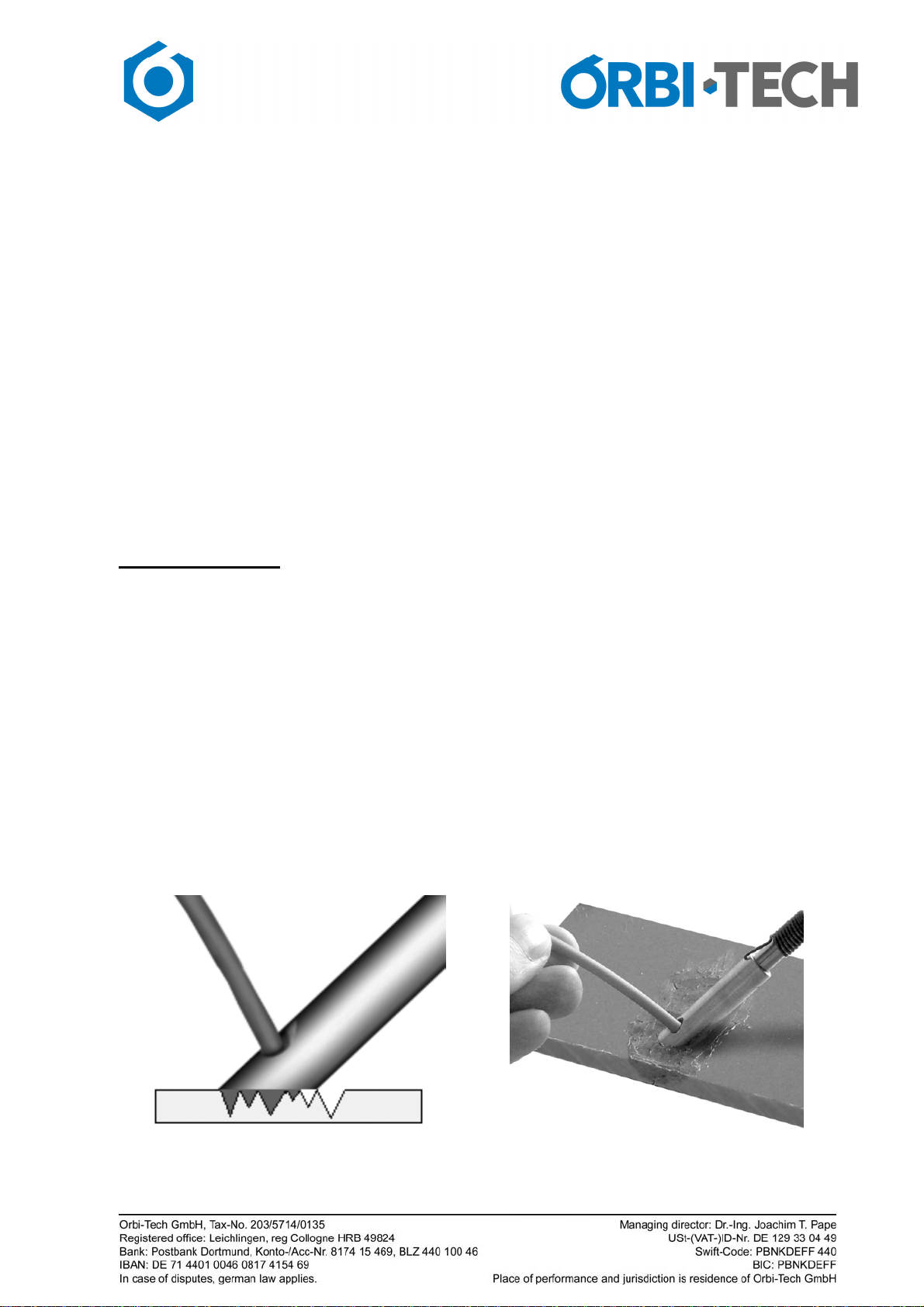

If the part has a crack, first you tack

weld the two parts. You can do this

by spot welding with the welding tip

with 2-5mm spacing (like stitching),

Next make sure penetration is

adequate and smooth the seam. If it

is possible to weld from both sides

the bond will be strong even with this

fairly simple method. If you can only

weld from one side, the bond is

not as strong but is enough to will

keep the parts from moving during the

welding process. To make the bond even stronger, the

reinforcing grid can be used. Cut a piece of the grid

with the scissors and put it on top of the crack. The grid

should extend at least 7 mm longer than the crack on either

side. Fix grid on the surface by using the flat part of the

welding tip to tack the grid bit by bit.

Start on one side in the middle of the grid.

Afterwards start to sink the mesh into

the plastic with the welding tip as

gently as possible with minimum

force. When the net sinks into the

plastic through melting of the surface,

pull back the foot about 2 to 3mm and

repeat the procedure. Push the

molten plastic on the hot part that you

have just worked on, thus covering

the mesh.

(picture 2). Repeat this procedure until the

mesh is fully below the surface. This requires patience. Plastic needs some time to

melt. Do not use excessive force or pressure.

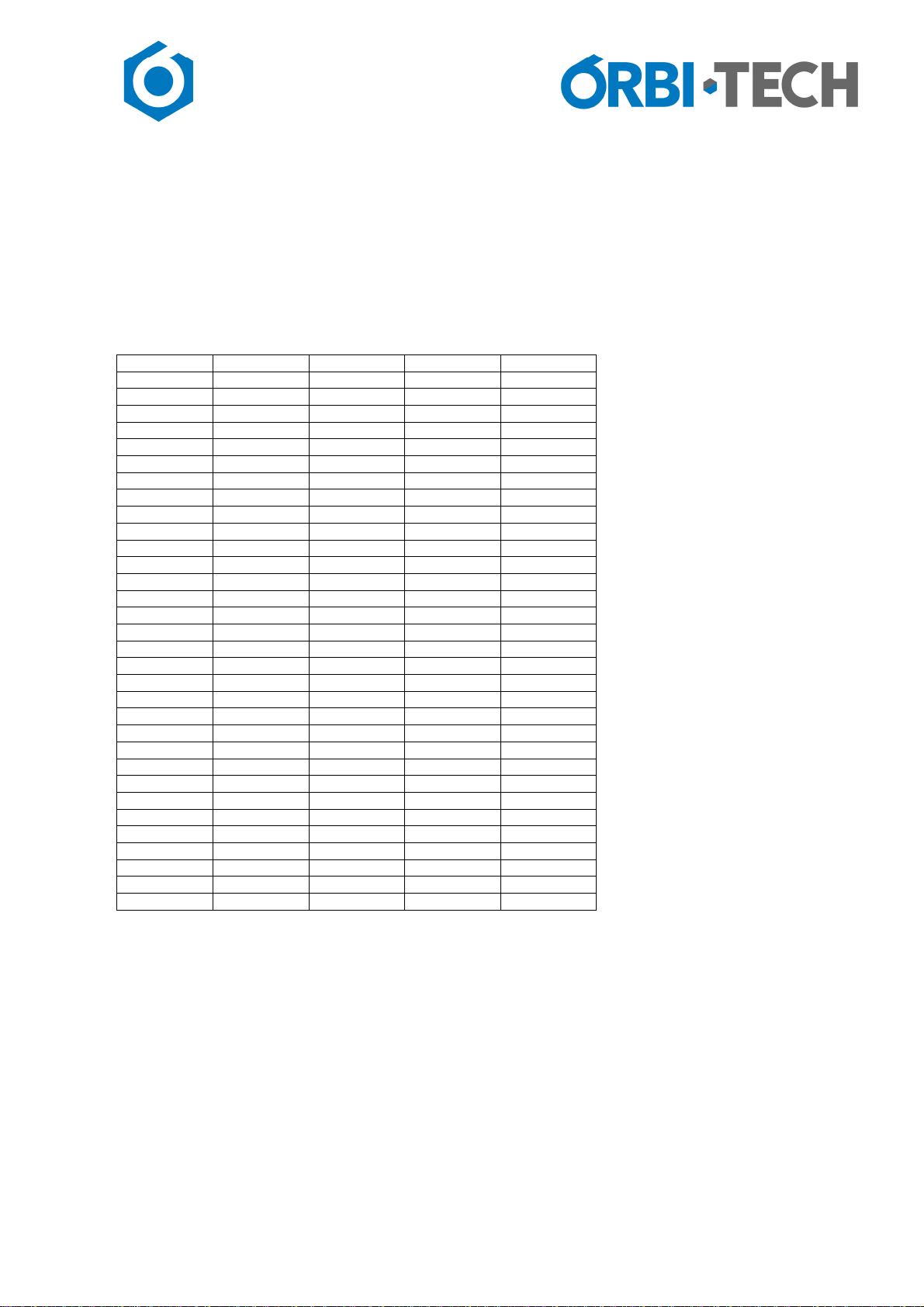

Tacking plasitc parts with

stitching action

lternating „stitching“ and smoothing

Reinforcing grid should overlap

the crack to be repaired by at

least 7mm

Sink in the metal mesh with heat

and gentle pressure Cover the mesh with melted

plastic