Operation Manual

"Open Frame Welding Head OSW Series"

9

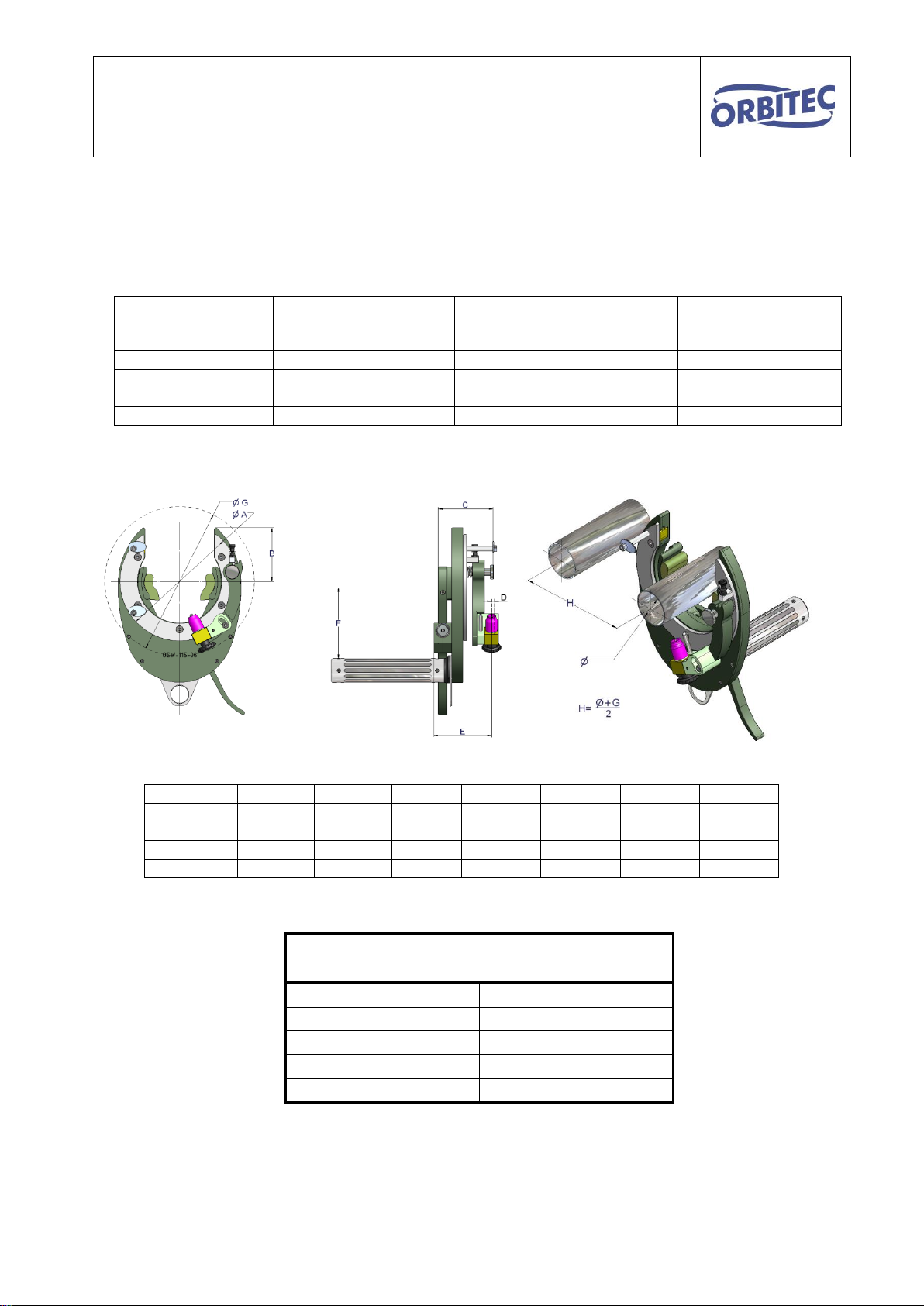

4. Functional principles of the open frame weld head

In the OSW welding tongs, the torch ring onto which the TIG torch is mounted, as well as the body of the

tongs, are open. The tool carrier is driven by several gear wheels. This ensures a continuous turning move-

ment in all welding positions.

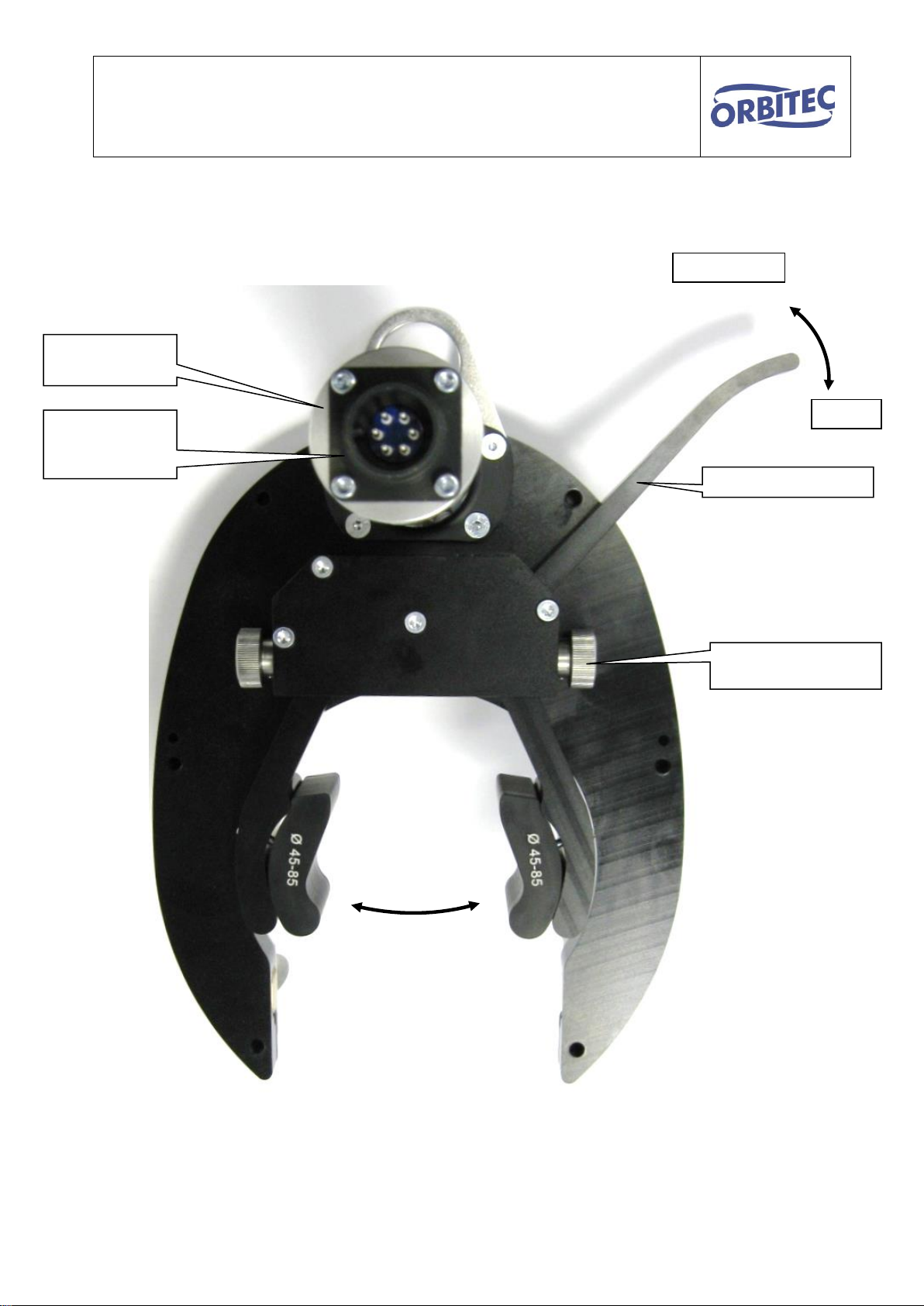

The head is adjusted to the diameter of the pipe using the adjustment screws of the quick-action clamping

lever.

It can be fastened immediately onto the tube over the weld joint.

The torch arm is loaded with a pressure spring at its point of rotation. After releasing the torch arm lock, the

torch is pressed onto the pipe. The torch arm with the TIG torch can be adjusted over the weld joint in three

dimensions.

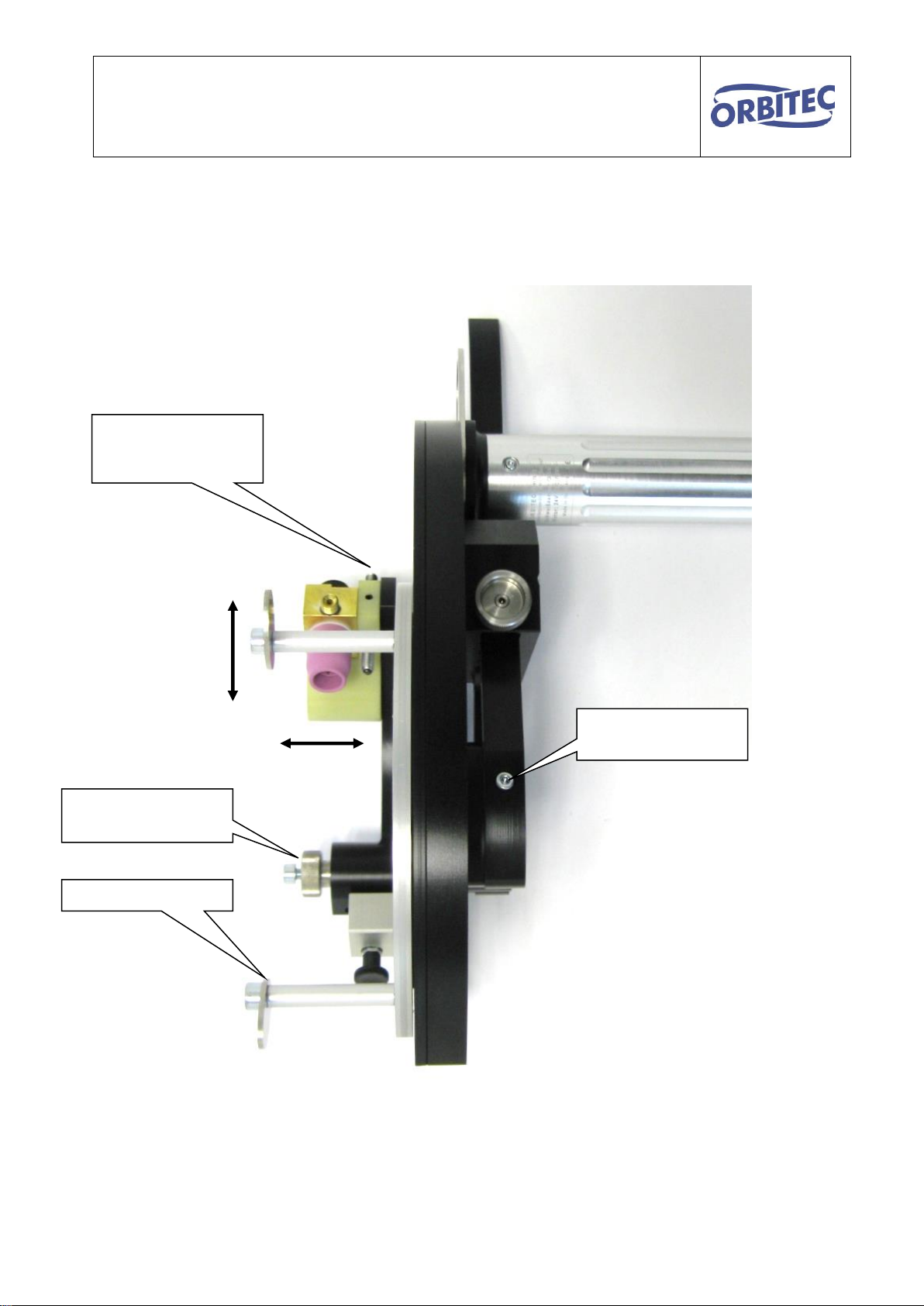

The arc distance is set via the torch height adjustment using a hexagon key and kept constant. The surface of

the pipe is continuously sensed.

The knurled screw provides fine adjustment to alter the side distance of the torch to the weld joint. The angle

of the torch head to the weld joint is continuously adjustable via the locking screws of the insulator and the

torch body Adjustment of the head for welding fillet welds is thus accomplished with little effort. For fillet welds,

torch holder which can be turned inwards and possibly also a "ceramic fillet weld nozzle" is required.

Welding with cold wire is possible by fitting the wire guide and the feed nozzle. The feed nozzle is attached to

the torch boy with two knurled screws It is adjustable. The wire guide hose is placed on the hose package

holder together with the hose package of the TIG torch before welding.

For further information see the Orbifeed operation manual.