Installation Manual: AdvanTex®AX20-RT Treatment Units

NIM-ATX-AXRT-1

Rev. 1.0, 1/10

© 2010 Orenco Systems®Inc.

Table of Contents

Products described in this manual are covered by one or more of the following U.S. Patents: 6,540,920; 6,372,137; 5,531,894; 5,492,635; 5,480,561; 5,360,556;

4,439,323. Products are also covered by foreign patents.

1

Before You Begin

As the installer of an onsite wastewater treatment

system, you play a crucial role. Homeowners,

neighbors, service providers, regulators, Dealers,

manufacturers ... we all rely on your expertise

and good work. At Orenco, we’ve worked hard to

make your installation as easy and “hassle-free”

as possible.

We’re very proud of this wastewater treatment

system. Like all our products, the AdvanTex®

AX20-RT Treatment Unit has gone through

extensive research, development, and field-test-

ing. Then each component is built to written spec-

ifications and subjected to quality review before

shipping. If this system or any of its components

possesses flaws that would inhibit its proper func-

tioning, please contact your authorized AdvanTex

Dealer. The Dealer can also provide repair and replacement instructions and replacement components. If there is no

authorized AdvanTex Dealer in your area, call Orenco Systems®, Inc. at 800-348-9843 or +1-541-459-4449.

Property owners, neighbors, regulators, Dealers, manufacturers, and

service providers all depend on your careful installation.

Before You Begin ............................................................. Page 1

Overview ..................................................................... Page 3

Installation Steps

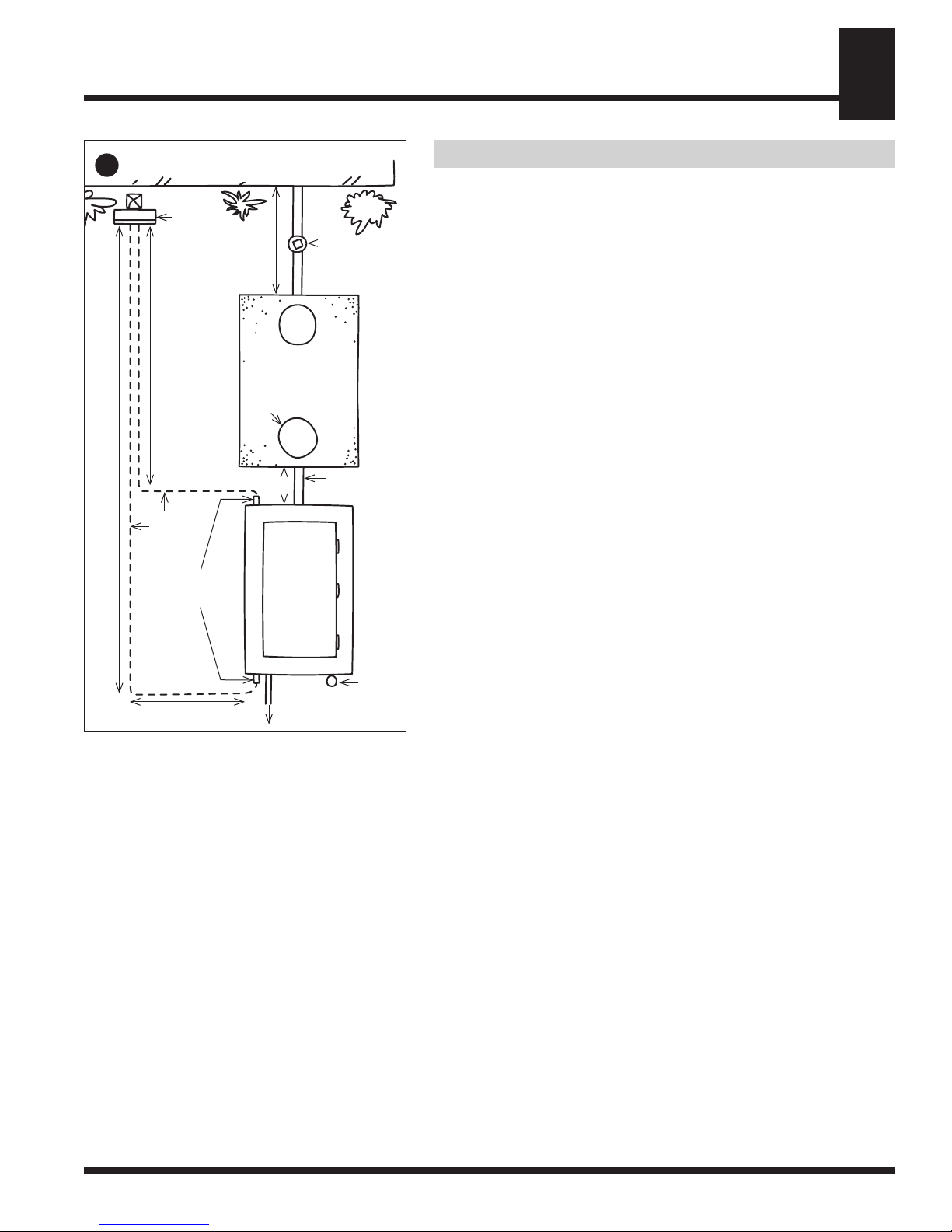

Step 1: Review or Sketch Site Plans ............................................. Page 4

Step 2: Excavate and Set Primary Tank ........................................... Page 5

Step 3: Install Risers and Water Test Tank ......................................... Page 5

Step 4: Install Effluent Filter .................................................... Page 6

Step 5: Excavate and Set AX20-RT Unit .......................................... Page 7

Step 6: Prep and Install Counterbuoyancy ......................................... Page 8

Step 7: Partially Backfill AX20-RT Excavation..................................... Page 9

Step 8: Test Watertightness of AX20-RT Unit ...................................... Page 9

Step 9: Connect Transport Line and Passive Air Vent ................................ Page 10

Step 10: Install and Test Control Panel ............................................. Page 11

Step 11: Test System Function ................................................... Page 14

Step 12: Complete Final Backfill ................................................. Page 15