10

-

The products from Orkel Compacon Ltd is well known for their high quality, reliability and strength. We will

therefore congratulate you, choosing of one of our machines.

To full our own goals, regarding quality and strength, Orkel Compacon Ltd has implemented a connuing

product - developing process. We are also carrying out a thorough quality control on all of our machines,

before leaving the factory.

You, as a owner or operator must read this operator’s manual with safety instrucons before start - up.

Read thoroughly, and familiarize with the rules and demands regarding machine - safety, use and mainte-

nance. Make daily maintenance as a roune.

By doing this, the machine will be safe to operate, contribute to a long life-span and a eecve ulizaon of

the machine.

With regards

-

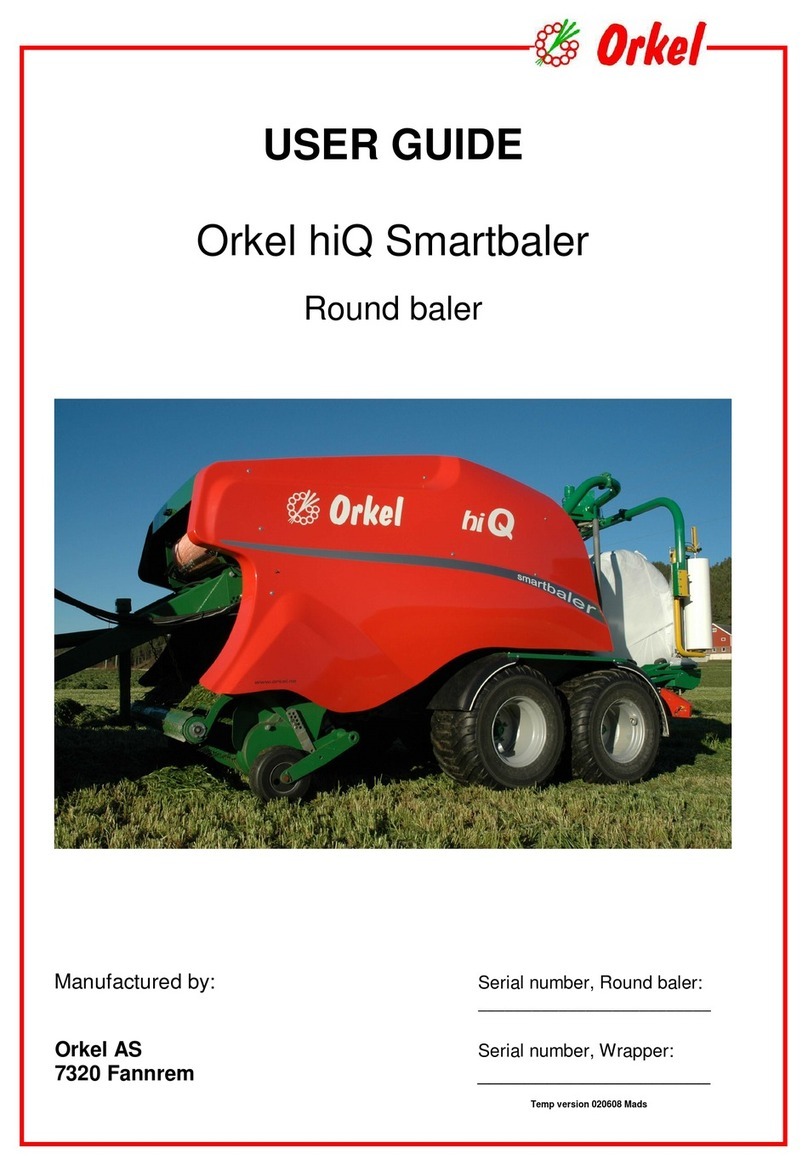

The compactor is designed for compressing so organic materials to bales. Then wrap them in plasc lm for

storage or transport. The compactor must only be used for this purpose.

Other materials can also be compressed, but have to be conrmed by Orkel Compacon AS in each case.

This due to warranty legislaons.

This machine is tested, controlled and passed the nal inspecon before leaving the plant.

Please check that this operator’s manual correspond with your machine.

-

One of our employees will set up the machine for the customer. A course in handling and operang the com-

pactor will be held at site if necessary. During start-up period we will be helpful with technical assistance and

answering quesons regarding the compactor.

Please see; Delivery - warranty formula in secon 1.4.