6

Part 2 Warranty. Declaration of conformity.

2.1 Warranty

Terms for end user:

Orkel AS warrants this machine against manufacturing defects for a period of 12 months from

the date of delivery to the end user.

The warranty is limited to:

1. The present value of the machine based on the maintenance performed, use and

condition.

2. The value of the damaged components.

3. Work hours calculated by Orkel AS.

4. Extent of repairs preapproved by Orkel AS.

Orkel AS is, under no circumstances, responsible for damage/circumstantial damage to third parties that may

be caused by the machine.

Important exceptions:

Ordinary wear and tear to rubber parts, tires, hydraulic hoses, blades, chains or bearings is not

covered by the warranty.

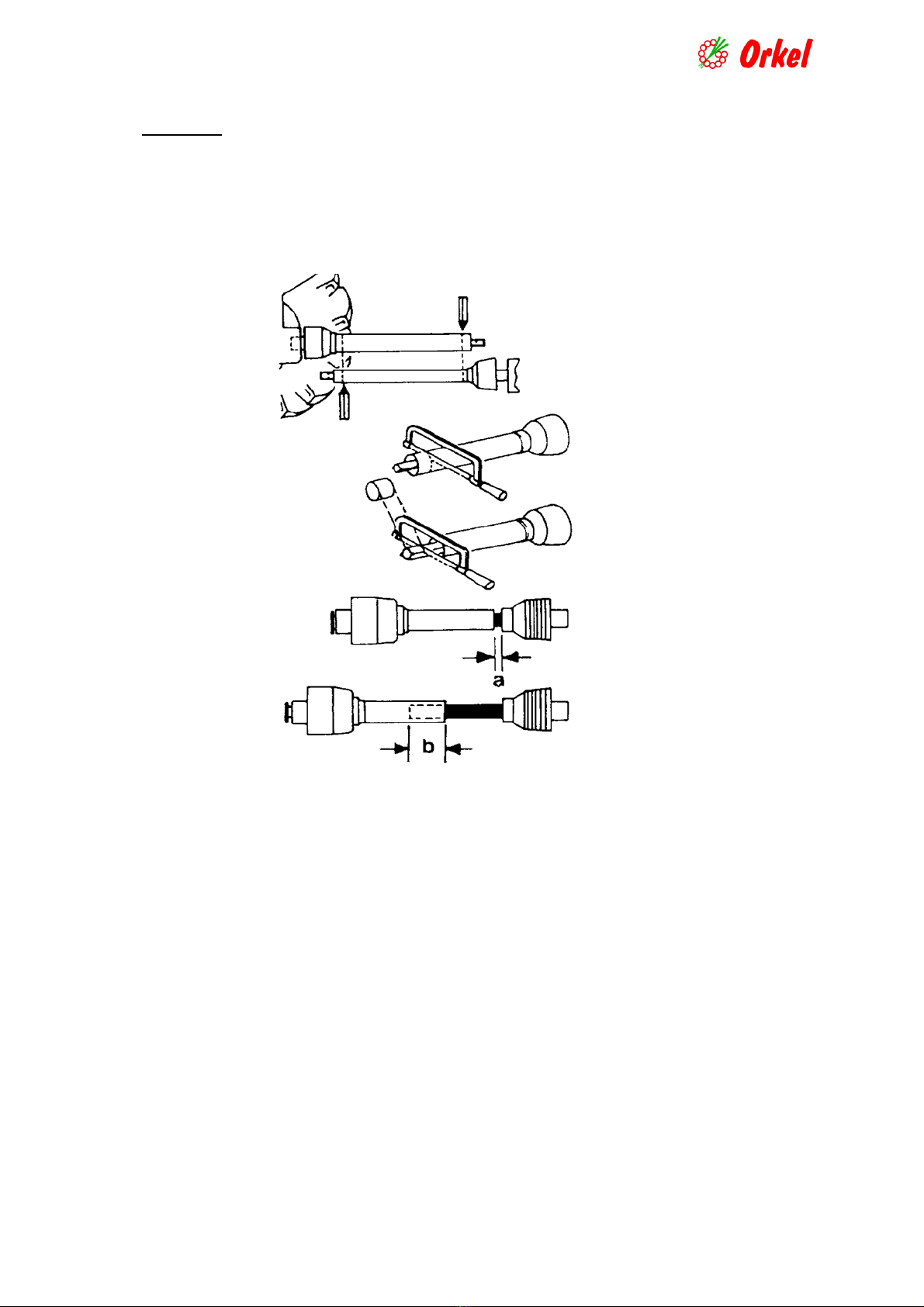

For the power transmission shaft, the supplier’s warranty regulations apply - see separate infor-

mation concerning the shaft.

The use of non-genuine parts, incorrect use and/or insufficient maintenance of the machine will lead to the can-

cellation or invalidation of the aforementioned warranty.

Extended warranty for slide bearings (bushings.

For machines with factory-mounted, fully automatic greased bearings, a 5-year warranty

(maximum of 50,000 bales) applies from the delivery date, for all slide bearings (bushing) for

rolls, based on the following:

Breakage to the slide bearing (bushing) is defined as material thickness of less than 0.2

mm.

Working hours for replacement are not included.

This warranty only applies if regular inspections and maintenance have been carried out

accordingly to the instructions outlined in this User Guide.

Extent and terms of the warranty:

The warranty covers the following situations:

Repair of faults caused by faults in the construction, materials, components, production,

mounting, alterations made by the factory or similar faults.

Faults and defects discovered before or after the product has been delivered to the cus-

tomer.

The product will be replaced or repaired as soon as possible, should a production or con-

struction fault occur, that potentially could represent a safety risk.

The terms of the warranty are not applicable if the defect/fault is caused by:

The product has not been handled according to the instructions provided by Orkel.

The product has not been serviced according to the instructions provided by Orkel..

The product has been modified,

The product has been installed or repaired, not corresponding to the instructions provided

by Orkel.

Non-genuine parts or standard components, not approved by Orkel, have been used.

Warranty work

Warranty work can only start after a specific agreement with the Orkel warranty representative.

Warranty work can be carried out either by the customer, an Orkel dealer or other workshop

preapproved by Orkel

To be continued next page.