Table of Contents

General Information

Salford Recommended Torque Values .........................................................................................................3

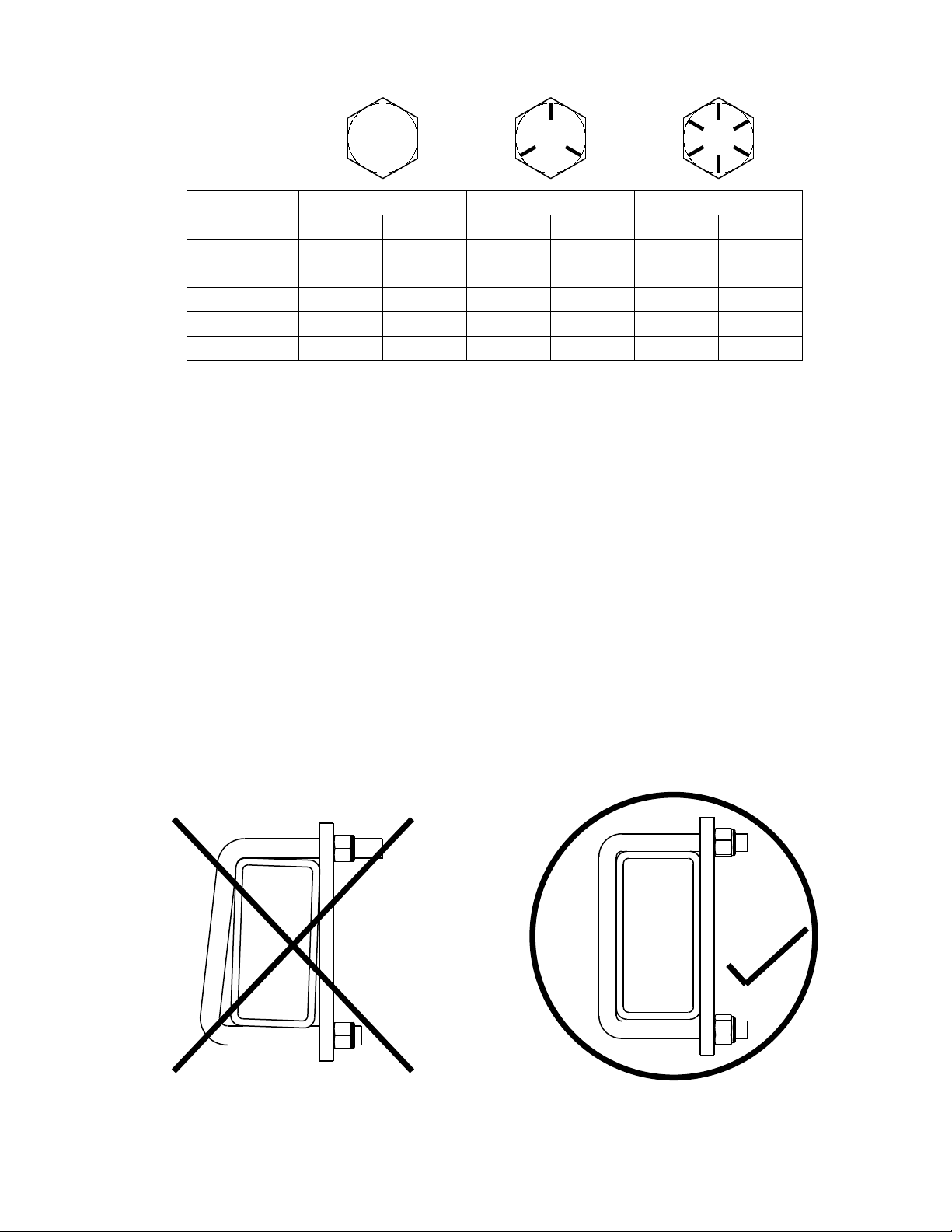

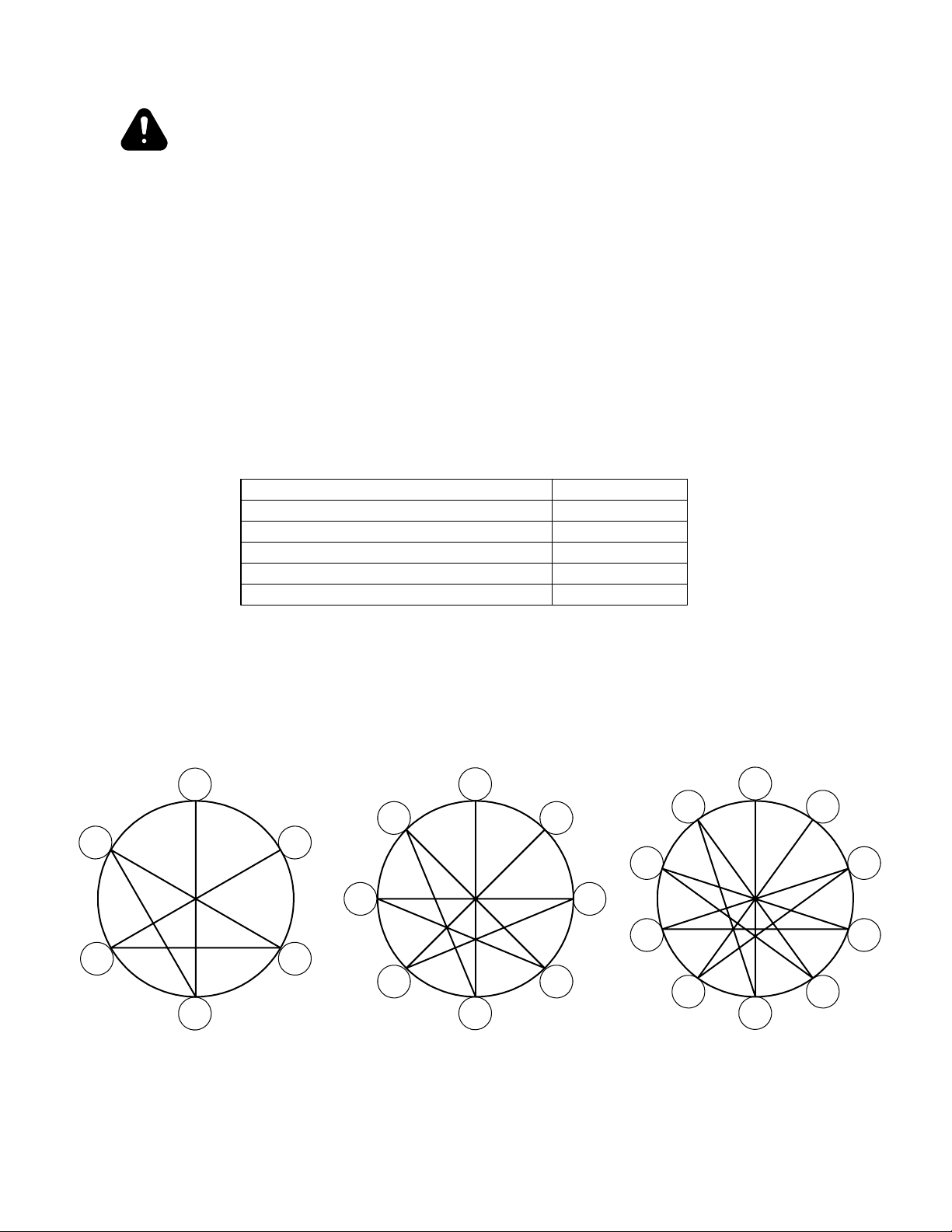

Wheel Torque Specications . ......................................................................................................................4

Tire Pressure Ratings ...................................................................................................................................5

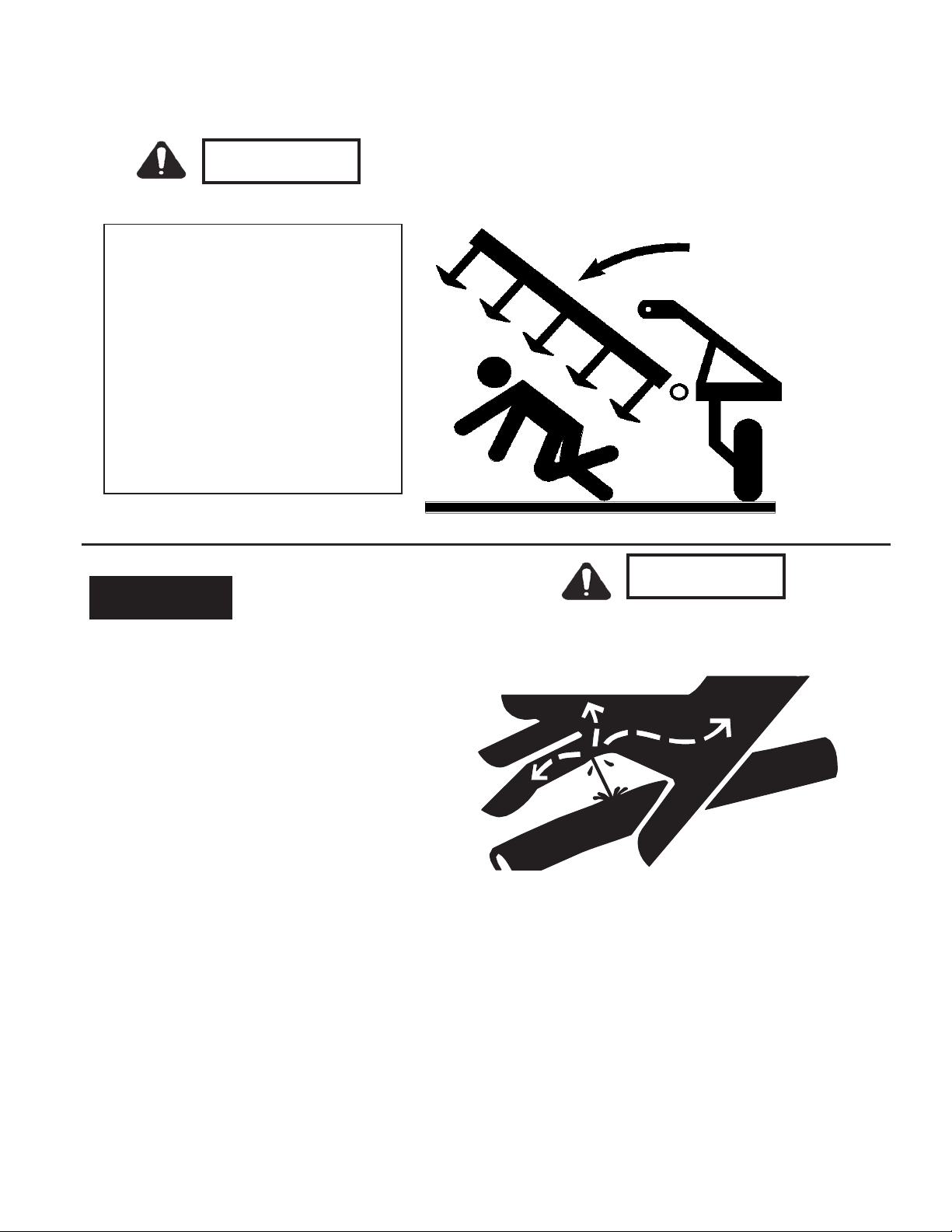

General Safety Precautions ..........................................................................................................................6

Frame and Tongue

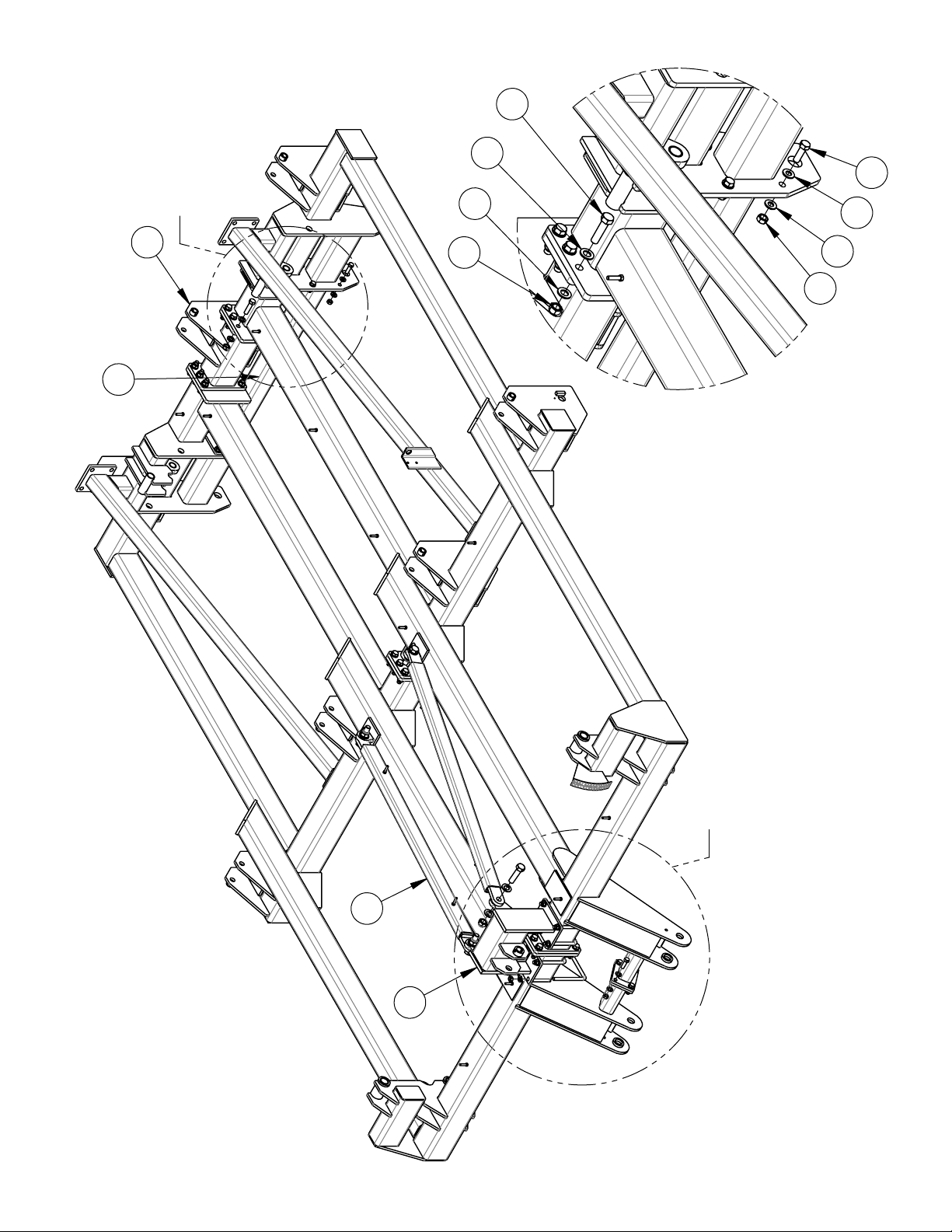

Frame Assembly. ..........................................................................................................................................8

Tongue Installation.....................................................................................................................................10

Telescope Mount Hose Holder...................................................................................................................13

Axles and Depth Control

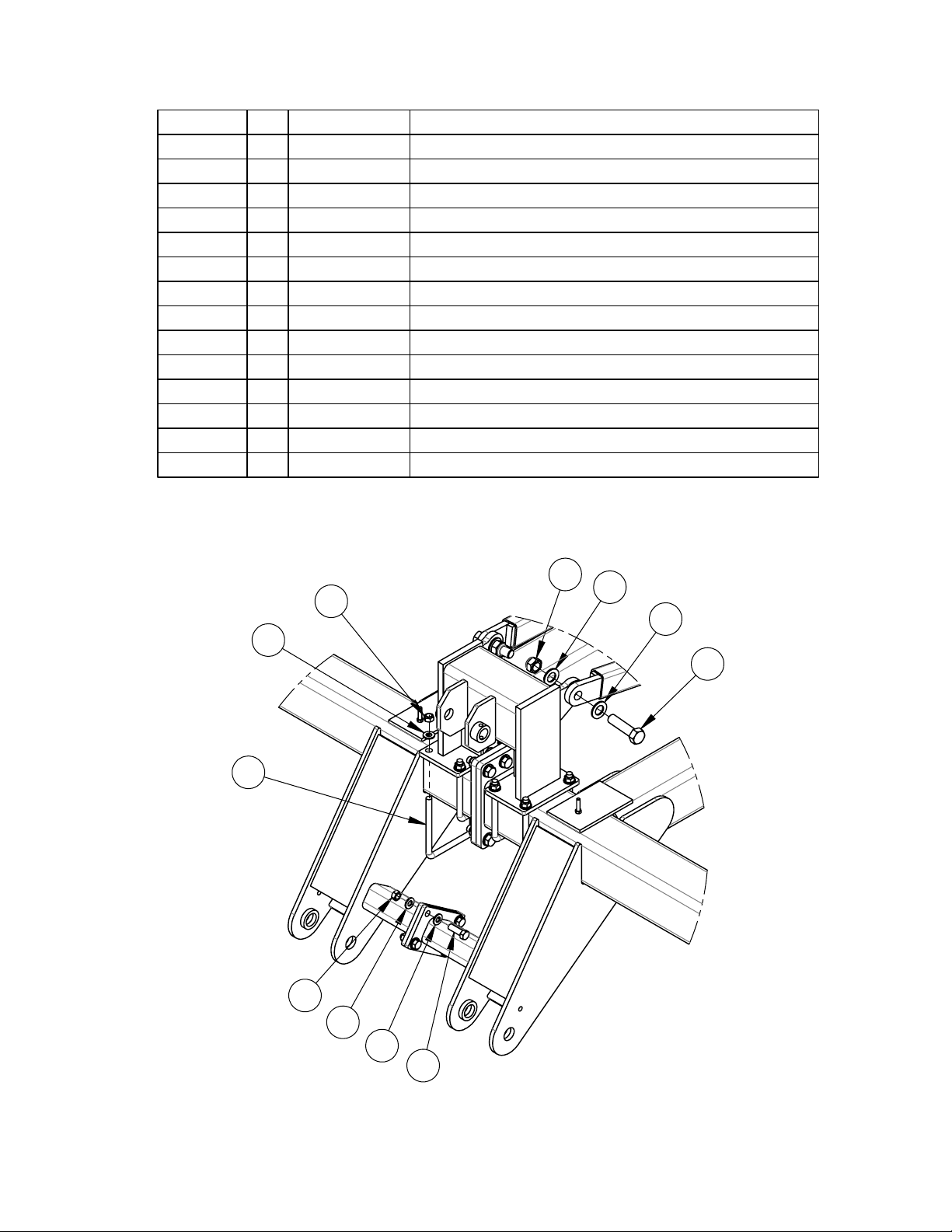

Axle Installation.........................................................................................................................................14

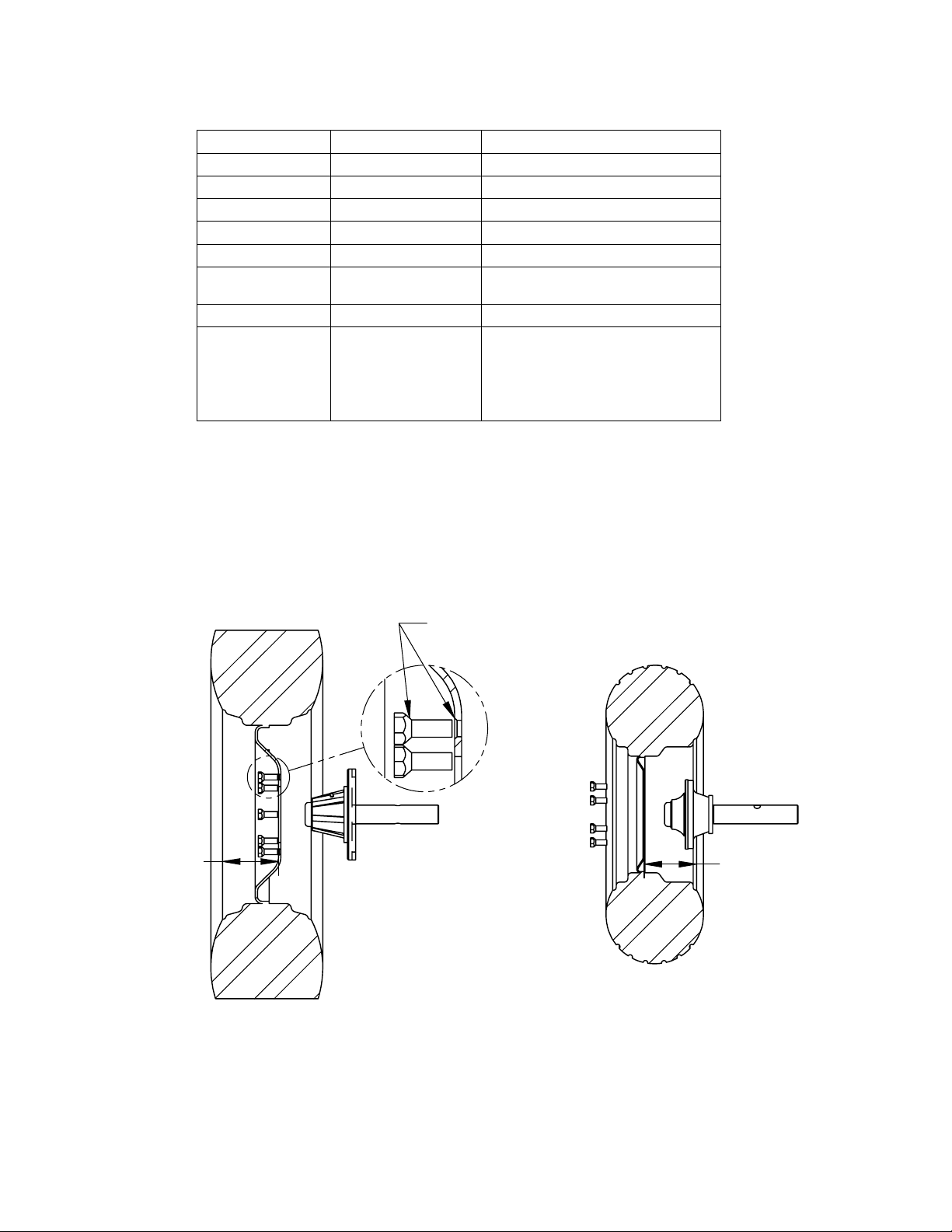

8000lb Hub and Spindle Assembly. ...........................................................................................................16

Depth Control Installation..........................................................................................................................18

Shank Assembly

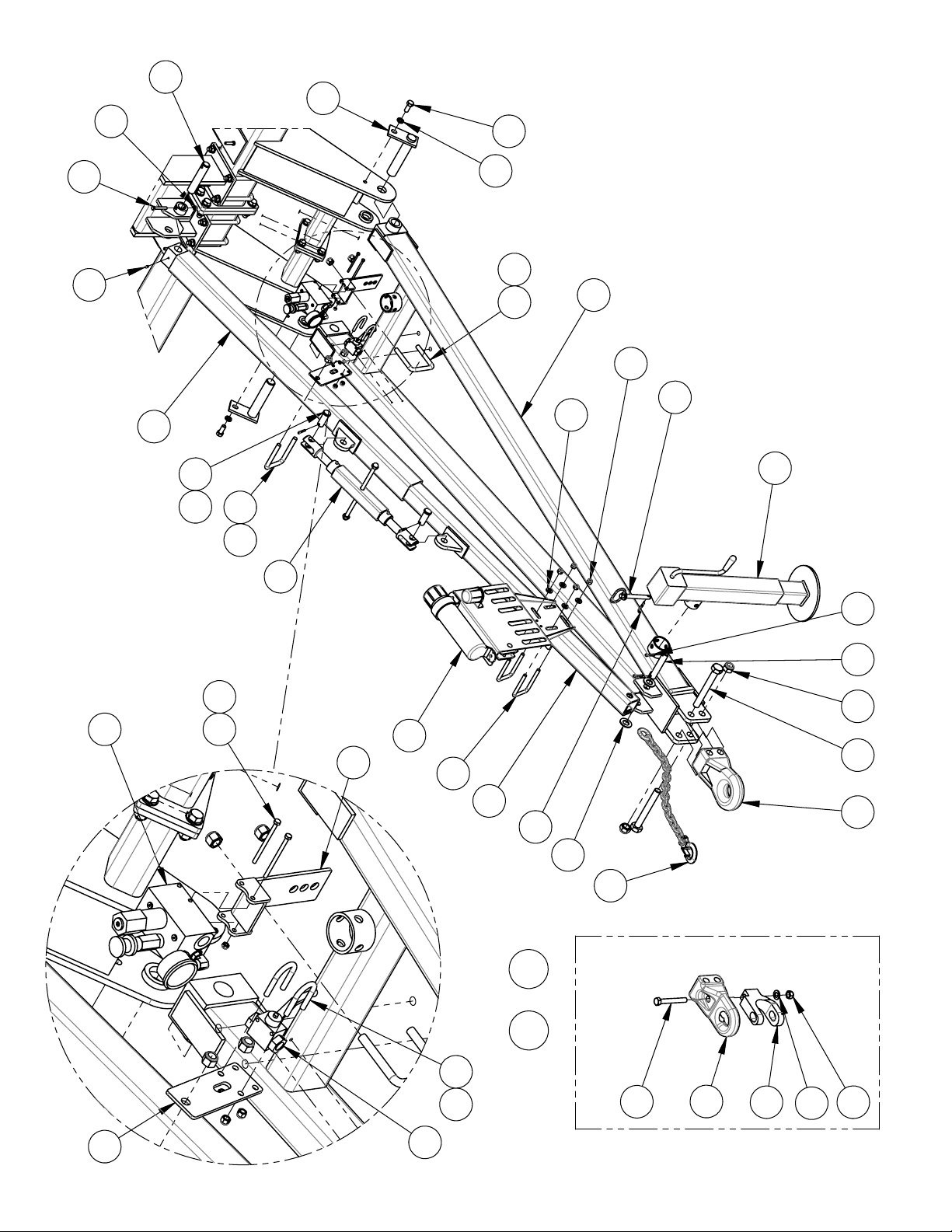

Shank Assembly. ........................................................................................................................................20

Parabolic Shank Assembly. ........................................................................................................................22

Chisel Ripper Shank Assembly..................................................................................................................23

Auto Reset Spring Trip . .............................................................................................................................24

Shank Lockout . ..........................................................................................................................................27

Disc Gangs

Disc Gang Installation................................................................................................................................28

Coulter Mount Assembly & Rebuild Instructions .....................................................................................31

Disc Gang Layout . .....................................................................................................................................36

Harrows

Harrow Layout with 1/2” Tines .................................................................................................................37

Harrow Installation ....................................................................................................................................38

62” Long Harrow Arm Assembly . .............................................................................................................40

1/2” Tine Harrow Assemblies . ...................................................................................................................42

14” Roller Harrow Assemblies ..................................................................................................................44

Hydraulics & Lights

Axle Lift Hydraulics .................................................................................................................................46

Disc Gang Hydraulics . ..............................................................................................................................48

Lights & SMV Install.................................................................................................................................50

Decal Layout..............................................................................................................................................52

Salford Farm Machinery Ltd. 07-2012

2012 9807 Assembly and Parts Manual

: http://texagropark.ru/