3

TABLE OF CONTENTS

W

ARRANTY

............................................................................................................... 6

W

HEELS

.................................................................................................................. 10

D

RAWBAR

............................................................................................................... 10

P

OWER TRANSMISSION

............................................................................................. 13

L

IGHTS AND BRAKES

................................................................................................ 13

H

YDRAULICS

........................................................................................................... 14

E

LECTRIC POWER SUPPLY

........................................................................................ 14

Main current cable.................................................................................................................................14

Control box.............................................................................................................................................14

N

ET BINDING

............................................................................................................ 16

Mounting the net roll..............................................................................................................................16

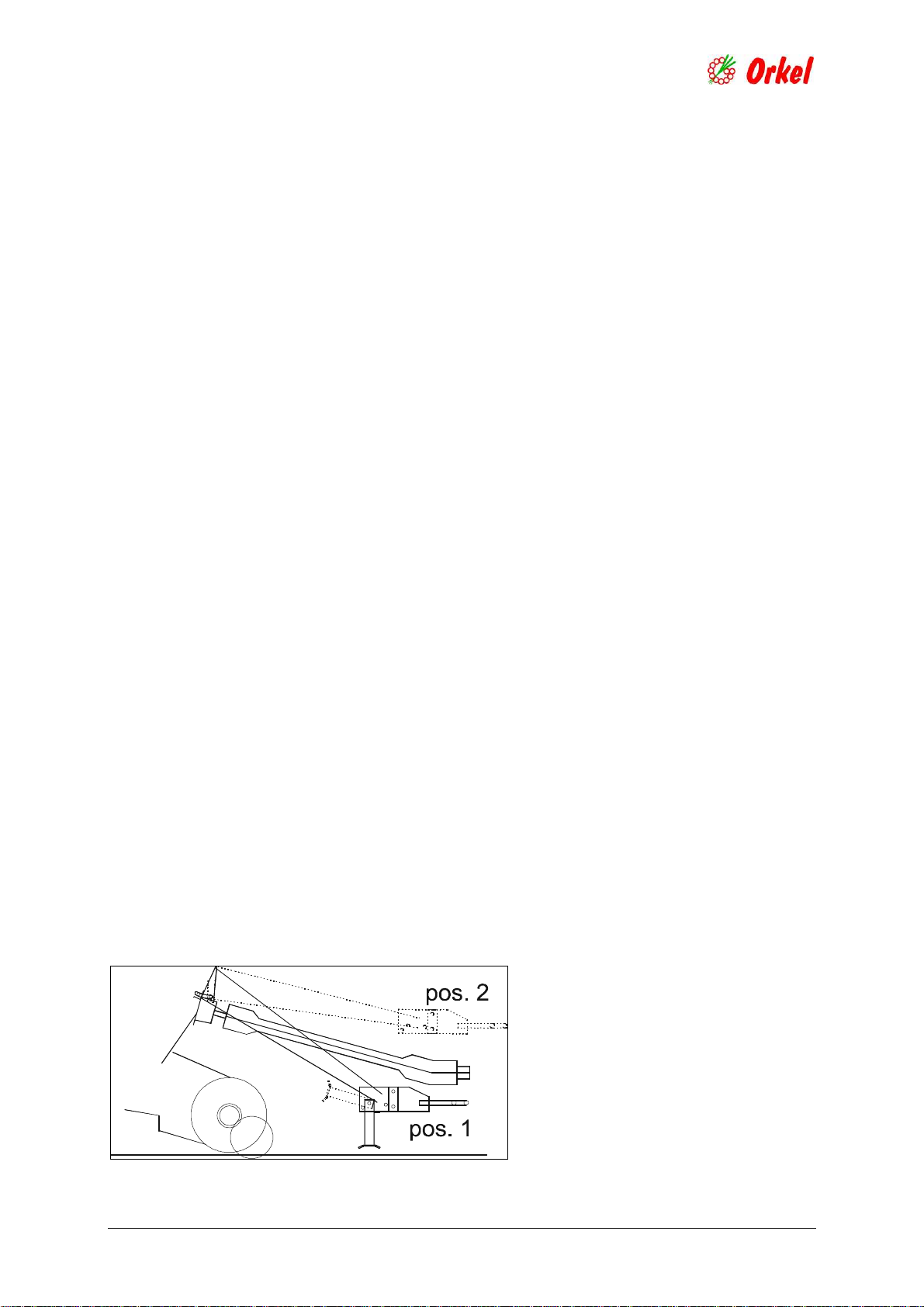

M

OUNTING THE FILM ROLL

(S

EE FIG

.

8)...................................................................... 17

A

SSEMBLY

.............................................................................................................. 19

B

ASIC FUNCTIONS

.................................................................................................... 20

C

ONTINUE IN THE PROGRAMME MENU

(

FROM THE START SCREEN

/

FIRST PICTURE

)......... 22

S

ETTINGS

:............................................................................................................... 22

Settings in Baling programs....................................................................................................................28

Counters settings....................................................................................................................................29

Calibrate settings....................................................................................................................................31

Chamber calibration...............................................................................................................................31

During operation....................................................................................................................................34

D

RIVING

.................................................................................................................. 36

B

ALER FILLING

........................................................................................................ 36

B

ALE BINDING

.......................................................................................................... 37

B

ALE WRAPPING

...................................................................................................... 38

If you run out of film whilst wrapping....................................................................................................38

If the wrapping arm hits an obstacle.......................................................................................................38

Transportation........................................................................................................................................38

W

ORK ROUTINES

..................................................................................................... 39

R

ECOMMENDATIONS FOR ACHIEVING MAXIMUM FODDER QUALITY

................................. 39

A

DVICE ON BALING STRAW WITH A FIXED CHAMBER BALER

.......................................... 40

P

ICKUP

................................................................................................................... 41

T

HE NET BRAKE

....................................................................................................... 41

N

ET LENGTH

............................................................................................................ 43

N

ET BLADES

............................................................................................................ 43

C

UTTING

................................................................................................................. 44

W

RAPPING UNIT SETTINGS CONDITIONS

/

BASIC INFORMATION

....................................... 44

B

EKA

M

AX FULLY AUTOMATIC GREASING SYSTEM

,

TYPE

EP1...................................... 45

Assembly of the net tying system.............................................................................................................45

Function.................................................................................................................................................46

Filling ....................................................................................................................................................46

Venting...................................................................................................................................................47

Maintenance and inspection...................................................................................................................47

Winter storage........................................................................................................................................47

D

AILY

/

REGULAR MAINTENANCE BEFORE USE

.............................................................. 48

G

ENERAL

................................................................................................................ 48

L

UBRICATION OF MANUAL LUBRICATION POINTS

......................................................... 49

Baler:.....................................................................................................................................................49

Wrapper:................................................................................................................................................49

N

ET BLADES

............................................................................................................ 50

C

HAINS

................................................................................................................... 51