8

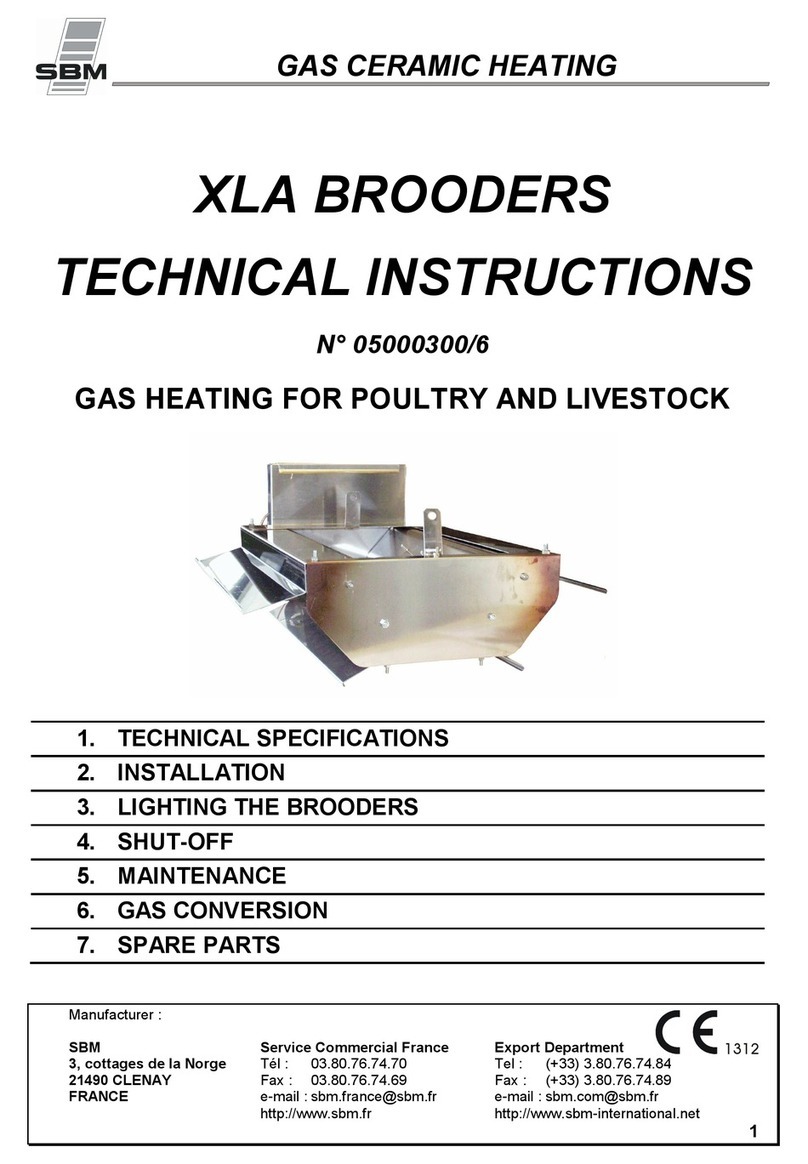

Blow the inside of the 2 burners Blow the surface of the ceramic

with compressed air. plaques with compressed air.

After cleaning the brooder, make sure that the brooder (surface of the ceramic

plaques, hanging bracket) has not experienced mechanical damage.

ONCE A YEAR, PERFORM A VISUAL INSPECTION OF ALL FLEXIBLE GAS HOSES,

ESPECIALLY AROUND THE HOSE CLAMPS.

6. GAS CONVERSION

The brooders are designed to operate with the following gas :

GAS PRESSURE

Propane 2.15 PSI

The equipment is adjusted for the type of gas and the pressure as displayed on the

rating plate.

For any change of the gas used, please contact your local SBM specialist.

7. SPARE PARTS

REP. SPARE PARTS

BR 208XL LEFT (the left burner when looking at the brooder

BR 212XL LEFT from the injection side)

BR 216XL LEFT

BR 208XL RIGHT (the right burner when looking at the brooder

BR 212XL RIGHT from the injection side)

BR 216XL RIGHT

METAL FILTER 300

METAL FILTER HOLDER 300

THERMOCOUPLE FA

10 LOCKING SCREW 6X100/30 (supplied by packs of 10)

INJECTOR BLOCK CAP

MAGNETIC HEAD 11.5

A

B

E

F

G

H

Compressed

air jet

(40 to 70 PSI max.)

Compressed

air jet

(40 to 70 PSI

max.)

Joints

Do not aim at the joints

between the ceramic plaques

C

D