System manual

SM0974113 A 01 7

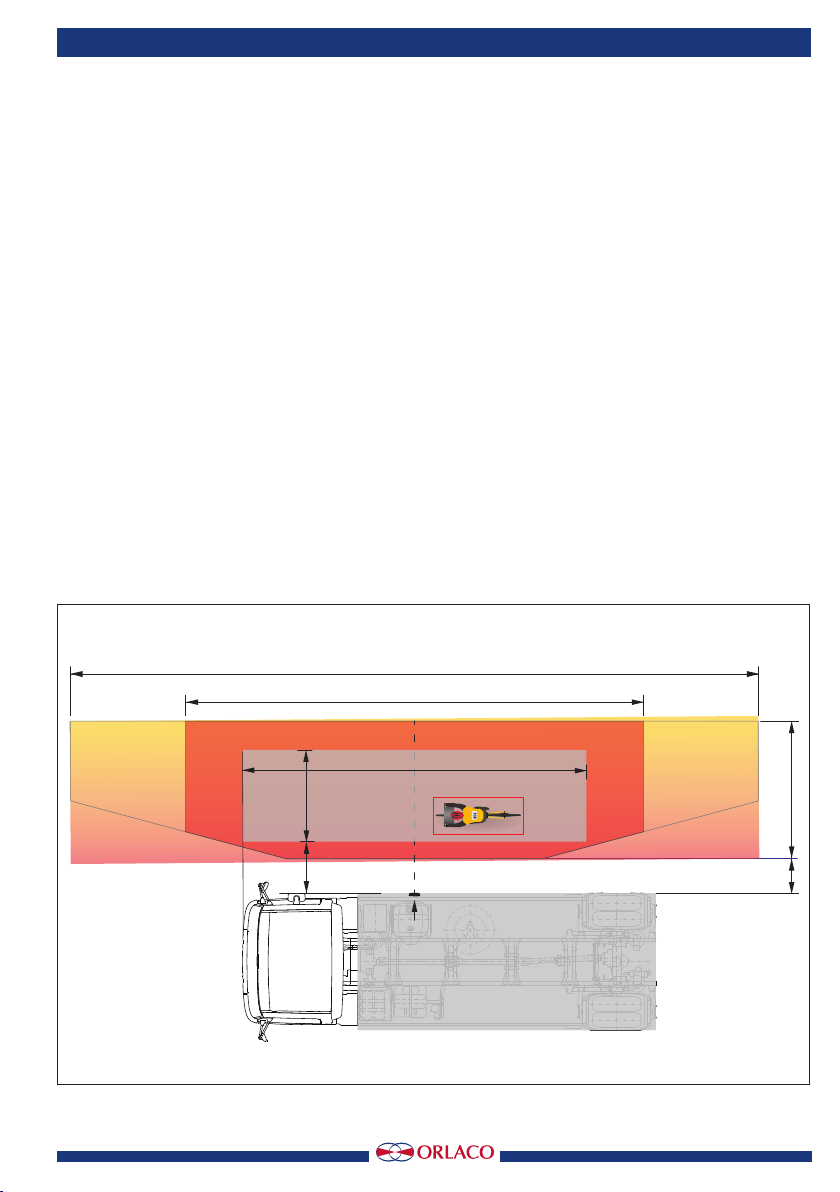

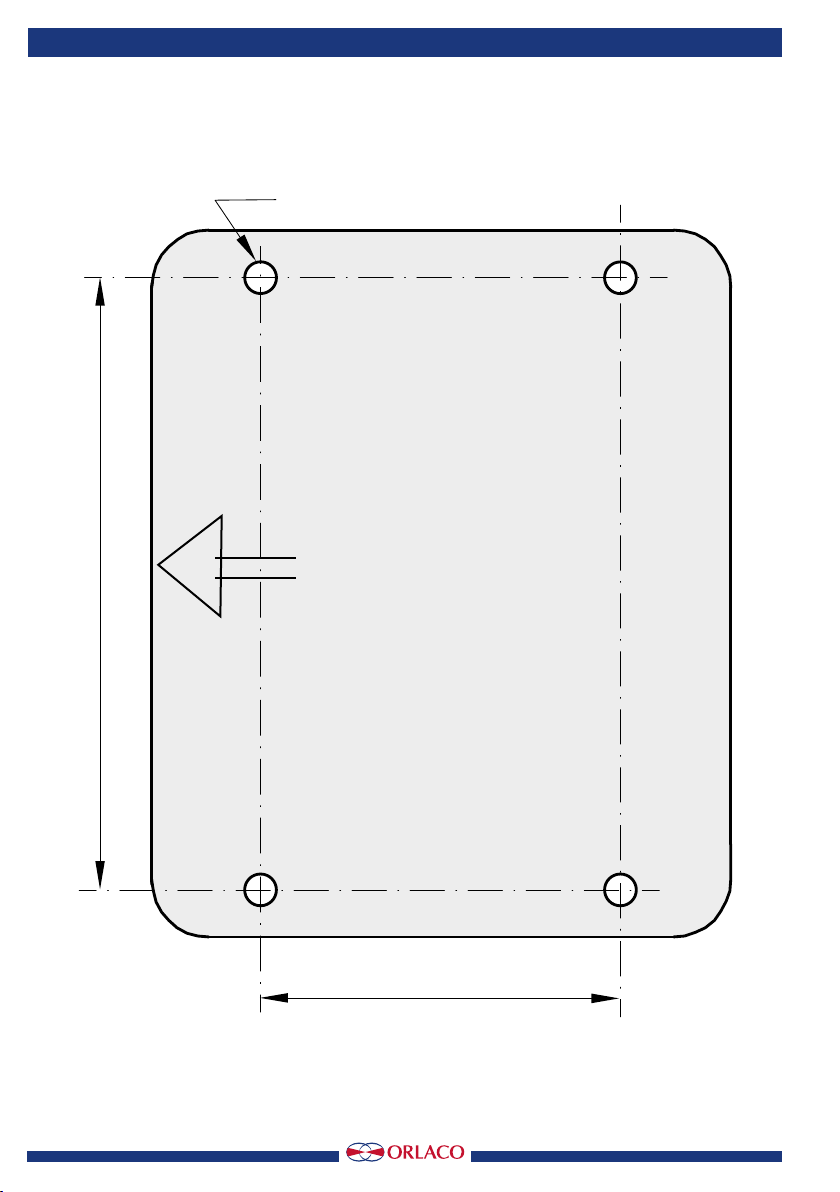

Figure 4

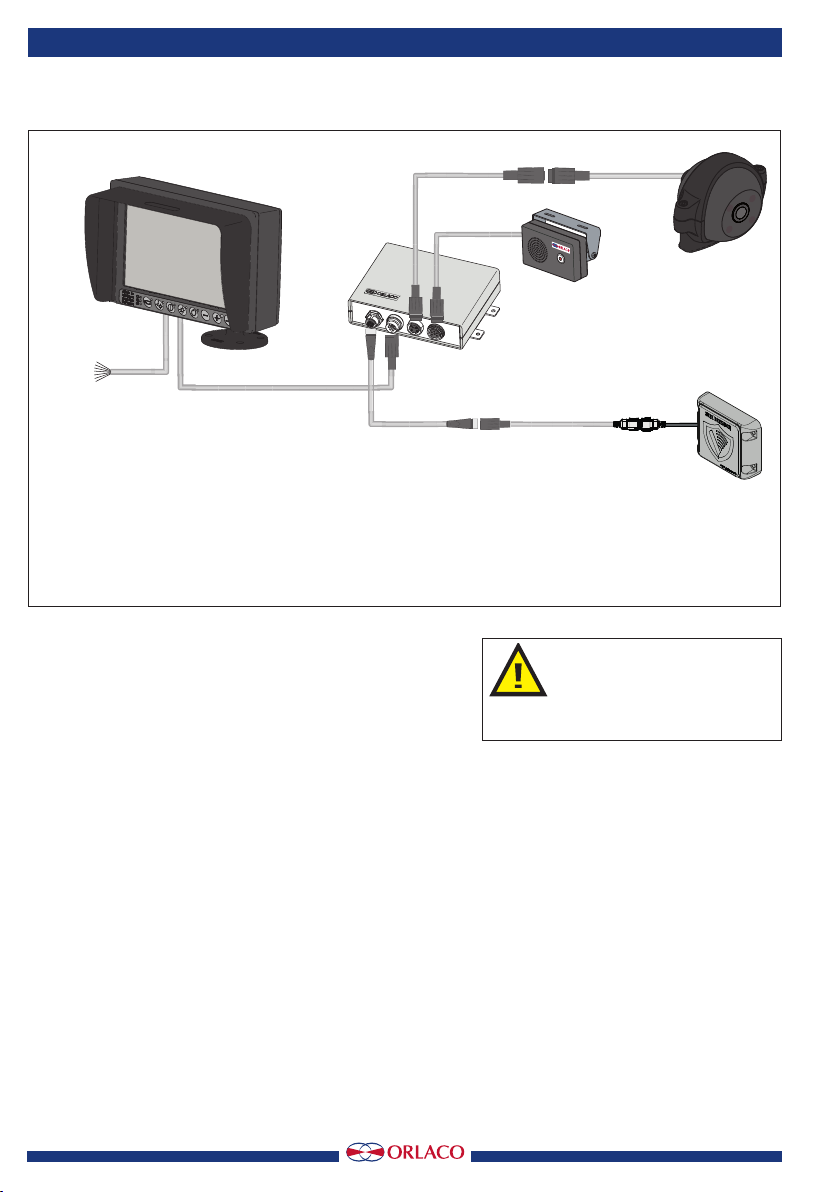

Figure 5

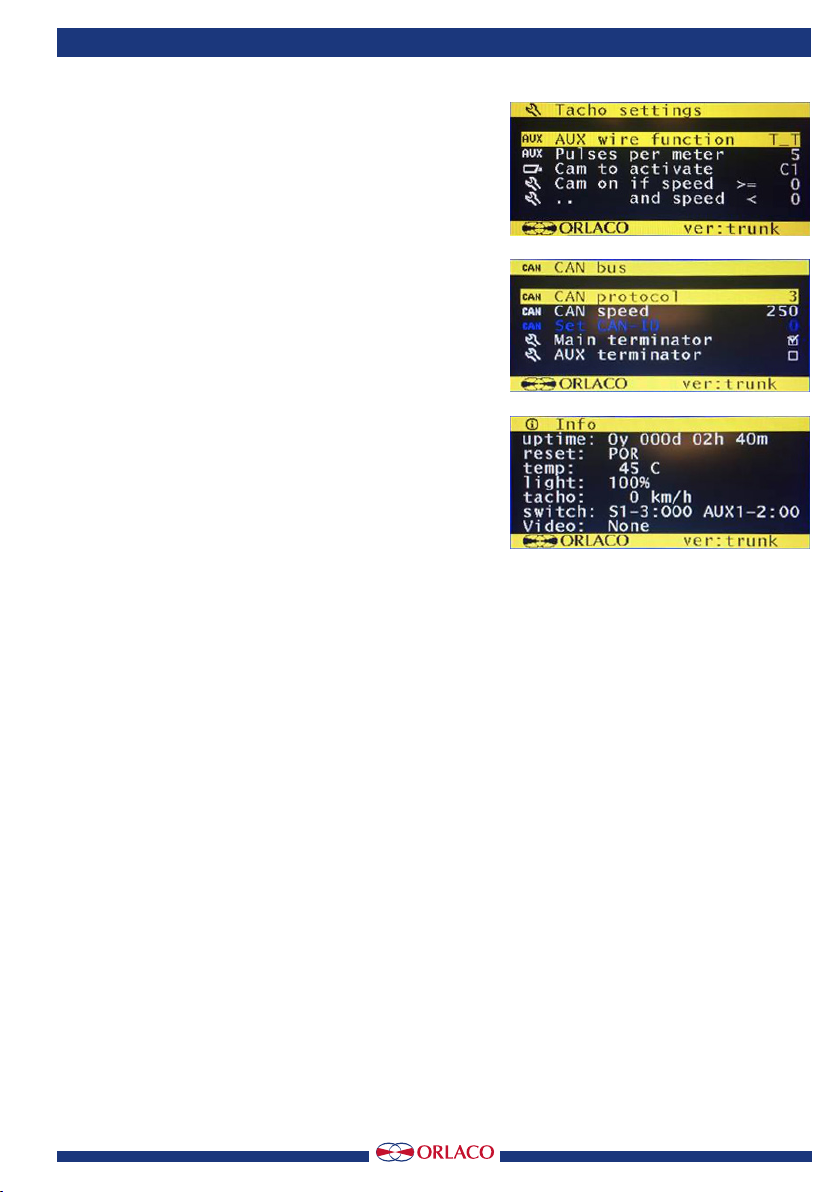

Figure 6

6. Monitor Service Menu

The SideEye monitor is programmed in the factory.

All necessary settings are made.

You can check this by entering the service menu. See Figure

4, 5 and the monitor manual.)

After installation open the info Page in the service menu and

scroll to the last page. See Figure 6.

Here you can check the connection of the Turn signal and

Speed signal during a test drive.

Check the speed. (should be almost the same as the tacho-

meter.)

Check AUX1 0= Turn signal off C= turn signal on

After this follow the test procedure for the detection zones.

7. Testing

1. Move the equipment to an open field larger than the

detection zone to test.

2. Clean the sensor face of any accumulation of dirt, mud,

snow, ice, or debris.

3. Visually inspect the attached wiring and cable and verify

that they are properly secured, not chafing or dangling

free where they could become snagged and damaged.

Inspect the Sensor and Monitor and verify that they are

securely attached to the equipment.

4. Place the sensor in active mode. Make sure the equip-

ment has been secured and remains stationary.

5. Verify the sensor is operational. Depending on operator

notification. Assure the detection zone has been cleared

of all obstacles. Any obstacles in the detection zone will

interfere with the test.

6. The assistant should walk towards the sensor while the

operator notes when the warning activates, signifying

the sensor has detected the assistant and identifying the

detection zone limits.

7. Next, the assistant should walk from the center of the

sensor field straight back, away from the equipment

(the center line of the detection zone) while the operator

notes when the warning (notification) stops.

8. The assistant should move a meter to the left of the

sensor and walk towards the sensor again while the

operator notes the warning.

9. Repeat the above step by moving out another meter to

the left and walking towards the sensor while the opera-

tor notes the warning.

10. Repeat this test sequence for the right side.

11. Finally, after the test, the operator and the assistant need

to communicate the details on the detection zone.

This test should be performed with two

people, the operator who remains in

the cab, and the assistant who walks

through the sensor eld (detection

zone).