Spectratime mRO-50

2.2 Physics Package (patent pending)

The main design characteristics of the PP are its low power consumption, small size and mass, along with minimal

environmental sensitivities and mechanical ruggedness.

All parts of the PP are incorporated into a DIL-14 package hermetically sealed o under Xenon atmosphere to reduce

temperature exchange by convection and minimize electrical power consumption.

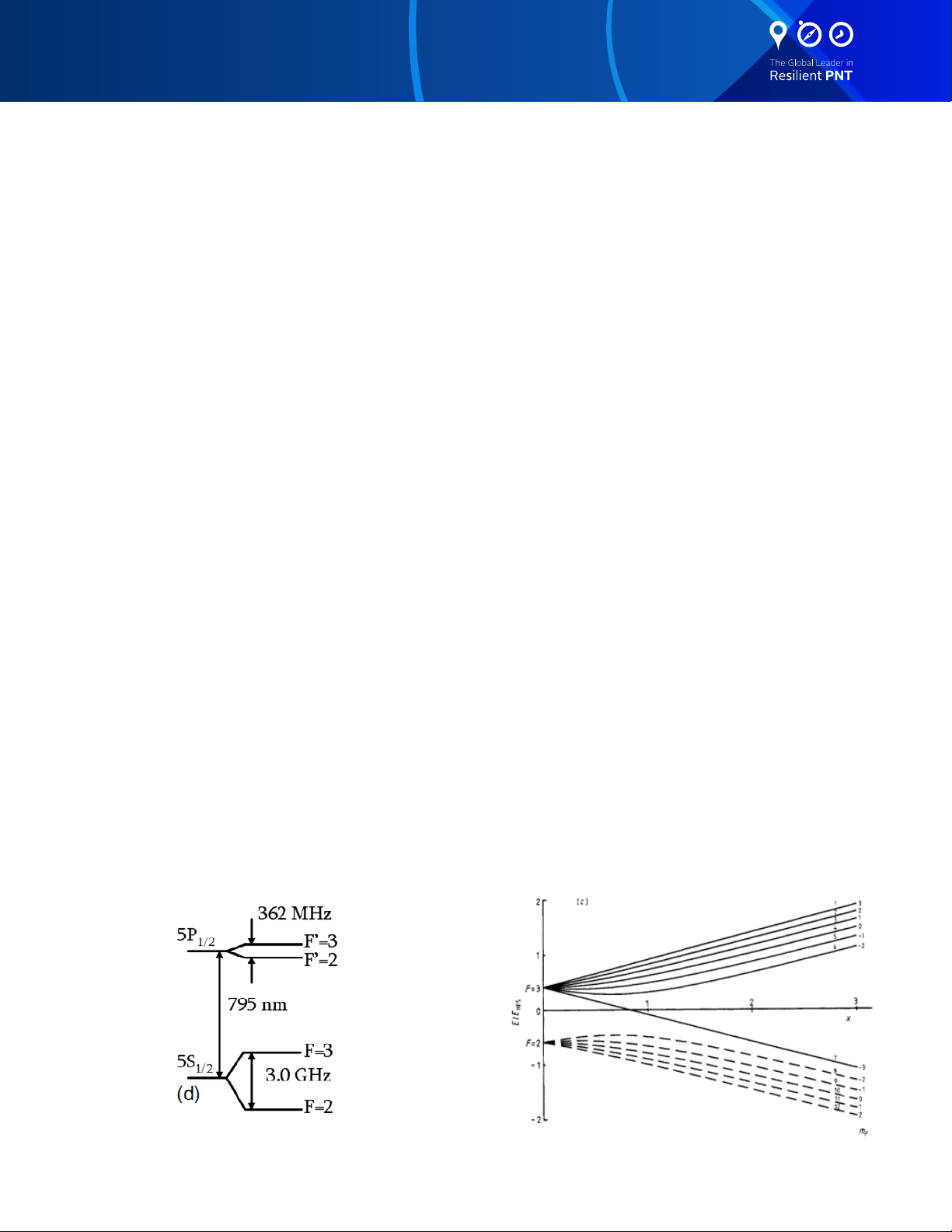

The light source selected for its compactness and low power consumption is a Vertical Cavity Surface Emitting Laser

(VCSEL) at 795 nm. It is coupled to a glass blown cell lled with Rubidium and buer gas surrounded by a cavity coupled

to the microwave signal.

The cavity has two purposes: 1) couple the Rubidium atoms to the microwave eld as mentioned previously but also 2)

transfer the heat to the cell and make a thermally stable environment around the glass cell as an oven. Both components,

VCSEL and Cell, are temperature stabilized.

The design is completed with Helmholtz coils, an optical lter and the photodetector.

2.3 Electronics Package

2.3.1 Atomic resonance signal capture

The mRO transition is a microwave transition at 3.036 GHz.

The microwave resonance which occurs as a dip in the optical signal after transiting the cell, is detected by a photodiode.

The basic purpose of the EP is to synchronize the entering microwave frequency, derived from a temperature compensated

crystal oscillator (TCXO), to this absorption dip. It is achieved by tuning the microwave frequency to maximum optical

absorption.

Frequency variations of the microwave signal are transformed into DC current changes at the photodetector. The dip,

visualized in the photocurrent versus microwave frequency curve of Figure 4 is very small: on the order of 1% of the total

photocurrent.

Since DC detection of the dip is not feasible, an AC detection method is used for the following reasons:

• The dip amplitude is very small compared to the total photocurrent.

• The slope of the derivative of the dip photocurrent versus microwave frequency corresponds to roughly 100 pA/

Hz. AC detection is the only solution to have a good signal/noise ratio since the photo-detector with associated

amplier are aected by icker noise.

The AC method involves square wave frequency modulation of the microwave signal at a rate of approximately 105

Hz. As shown in Figure 4, the modulated microwave frequency ips between 2 discrete frequency values f1 and f2. The

resulting photo-current i(t) appears also (after the transient) at 2 discrete values i1 and i2. The dierence between i1

and i2 produces the error signal used to adjust the crystal oscillator center frequency until the mean value of f1 and f2 is

exactly equal to the rubidium hyperne frequency.