Ortlieb Präzisionssysteme GmbH & Co. KG • Jurastr.11 • 73119 Zell unter Aichelberg • Germany

3

Content:

1

General ..................................................................................................................................4

1.1

Introduction.....................................................................................................................4

1.2

Guarantee ......................................................................................................................5

1.3

Intended Use ..................................................................................................................6

1.4

Initial start-up..................................................................................................................6

2

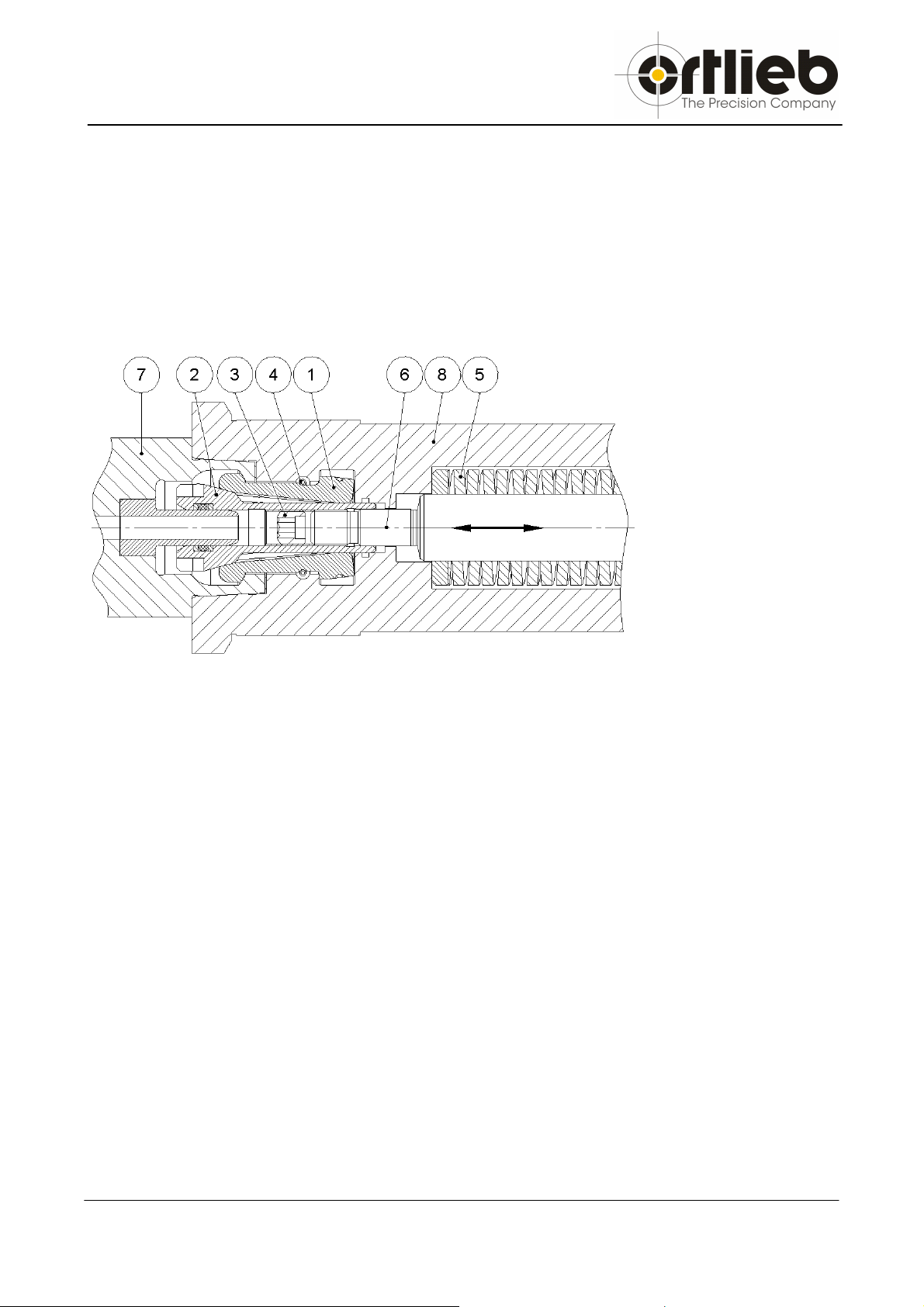

Product-description ................................................................................................................7

2.1

Tool-Grip

®

Standard .......................................................................................................8

2.2

Tool-Grip

®

Repair-kit.......................................................................................................8

2.3

Tool-Grip

®

Maintenance-free ..........................................................................................9

2.4

Tool-Grip

®

with holding function....................................................................................10

3

Accessories..........................................................................................................................11

3.1

Technical data ..............................................................................................................11

3.2

Spare parts...................................................................................................................11

4

Mounting instruction .............................................................................................................12

5

General Safety Instructions ..................................................................................................14

5.1

Checklist for Installation................................................................................................16

5.2

Troubleshooting............................................................................................................18

6

Assembly declaration ...........................................................................................................19

7

Shipping data .......................................................................................................................20