OSCO VS-GSLG User manual

Nov. 2006, Rev. 15

VS-VS-

VS-VS-

VS-GG

GG

GSS

SS

SLL

LL

LGG

GG

G

INSINS

INSINS

INSTT

TT

TALAL

ALAL

ALLL

LL

LAA

AA

ATT

TT

TION GUIDEION GUIDE

ION GUIDEION GUIDE

ION GUIDE

UL325 COMPLIANCE REQUIRES THE USE OF CONTACT EDGES

OR PHOTOELECTRIC CONTROLS ON ALL AUTOMATIC OR

REMOTELY-CONTROLLED GATE OPERATORS.

OPERATOR SPECIALTY COMPANY, INC.OPERATOR SPECIALTY COMPANY, INC.

OPERATOR SPECIALTY COMPANY, INC.OPERATOR SPECIALTY COMPANY, INC.

OPERATOR SPECIALTY COMPANY, INC.

CASNOVIA, MI 49318 • U.S.A.

®

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 2 -- 2 -

- 2 -- 2 -

- 2 -

TABLEOFCONTENTSTABLEOFCONTENTS

TABLEOFCONTENTSTABLEOFCONTENTS

TABLEOFCONTENTS

PRE-INSTALLATIONINFORMATION

Gate Operator Classifications.........................................................................................................................................................3

Safety Information and Warnings ....................................................................................................................................................3

Pre-Installation Information.............................................................................................................................................................3

Warranty ...........................................................................................................................................................................................3

INSTALLATION

Unpacking and Inspection ..............................................................................................................................................................4

Pre-Installation Information.............................................................................................................................................................4

Installation Instructions ...................................................................................................................................................................4

Electrical Instructions and LImit Switch Adjustments.....................................................................................................................5

Installation Instructions Drawing ....................................................................................................................................................6

Four Switch Rotary Limit Box Photo ................................................................................................................................................7

Torque Limiter Adjustment ..............................................................................................................................................................8

Manual Disconnect..........................................................................................................................................................................8

Maintenance ....................................................................................................................................................................................9

CONTROLBOARDADJUSTMENTSandACCESSORY CONNECTIONS

Control Board Adjustments ...........................................................................................................................................................10

Terminal Connection Descriptions ............................................................................................................................................... 11

Current Sensing Adjustments.......................................................................................................................................................12

Close Direction Current Sense Adjustment .................................................................................................................................12

Open Direction Current Sense Adjustment ..................................................................................................................................12

Maximum Run Timer Adjustment..................................................................................................................................................12

Auto Close Timer Adjustment .......................................................................................................................................................12

Master/Slave Connection ..............................................................................................................................................................12

Onboard L.E.D. Indicator Descriptions .........................................................................................................................................13

Important Notes for Installation of Master/Slave Applications ......................................................................................................14

Surge Protector Instructions..........................................................................................................................................................14

Control and Accessory Connection Illustrations .................................................................................................................... 15-18

ILLUSTRATIONS

Loop Layout Illustration .................................................................................................................................................................19

Edge Layout Illustration #1............................................................................................................................................................20

Edge Layout Illustration #2............................................................................................................................................................21

Photo Eye Illustration.....................................................................................................................................................................22

Picket Gate Illustration...................................................................................................................................................................23

Track Gate Illustration....................................................................................................................................................................24

TROUBLESHOOTING ..........................................................................................................................................................................25

PARTS LISTS

How to Order Replacement Parts .................................................................................................................................................25

Model VS-GSLG Mechanical Parts Exploded View .......................................................................................................................26

Model VS-GSLG Mechanical Parts List .........................................................................................................................................27

Model VS-GSLG Control Box Exploded View and Parts List - AC Tech ........................................................................................28

Programming Instructions for Variable Speed Drive - AC Tech....................................................................................................29

Model VS-GSLG Control Box Exploded View and Parts List - Hitachi ..........................................................................................30

Programming Instructions for Variable Speed Drive - Hitachi......................................................................................................31

Wiring Specifications.....................................................................................................................................................................32

PREVENTATIVEMAINTENANCE .........................................................................................................................................................34

GATEOPERATORINSTALLATION CHECKLIST ..................................................................................................................................36

CAUTION!

DO NOT INSTALL

CONTROLSONA

GATE ORFENCELINE

CAUTION!

ONLYQUALIFIED SERVICE

TECHNICIANSSHOULD

WORK ON AN OSCO

SLIDEGATEOPERATOR

CAUTION!

DO NOT INSTALL

CONTROLS

ONTHEOPERATOR

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 3 -- 3 -

- 3 -- 3 -

- 3 -

ReadthefollowingbeforebeginningtoinstallOSCOslidegate

operators:

1. Readtheyellow“Safety Instructions” brochure enclosed

with the packet of information. If you do not have one,

pleasecallOSCOat1-800-333-1717torequestone. Read

andfollowall instructions.

2. All electrical connections to the power supply must be

made by a licensed electrician and must observe all

national and local electrical codes.

3. A separate power-disconnect switch should be located

neartheoperatorsothatprimarypowercanbeturnedoff

whennecessary.

4. Install the enclosed warning signs on both sides of the

gate. Each sign must be plainly visible from the side of

the gate on which they are mounted.

5. Never reach between, through or around the fence to

operatethegate.

6. You must install all required safety equipment.

GATEOPERATORGATEOPERATOR

GATEOPERATORGATEOPERATOR

GATEOPERATOR

CLASSIFICATIONSCLASSIFICATIONS

CLASSIFICATIONSCLASSIFICATIONS

CLASSIFICATIONS

PRE-INSTALLATIONINFORMATIONPRE-INSTALLATIONINFORMATION

PRE-INSTALLATIONINFORMATIONPRE-INSTALLATIONINFORMATION

PRE-INSTALLATIONINFORMATION

Before unpacking, inspect the carton for exterior damage. If

youfinddamage,advisethedeliverycarrierofapotentialclaim.

Inspect your package carefully. You can check your acces-

sory box parts with the enclosed packing slip for your conve-

nience.Claimsforshortageswillbehonoredforonly30days

fromthedate of shipment.

Before installing the operator, read this manual completely

toensureallrequirementsfor proper installation are present.

Verify that the voltage to be used matches the voltage of the

operator.

SAFETYINFORMATIONSAFETYINFORMATION

SAFETYINFORMATIONSAFETYINFORMATION

SAFETYINFORMATION

ANDWARNINGSANDWARNINGS

ANDWARNINGSANDWARNINGS

ANDWARNINGS

IMPORTANT!!IMPORTANT!!

IMPORTANT!!IMPORTANT!!

IMPORTANT!!

Beforeinstallingthegateoperator, makesurethegate’sslide

isfreeandlevelthroughouttheentireopeningdistance.Ifthe

gate does not seem to operate properly, it may affect the op-

erator performance or greatly shorten the life of the unit. The

gate should be designed so that airflow through the fabric is

ampletopreventwindresistanceanddrag.

All gate operators can be divided into one of four different

classifications,dependingontheirdesign and usage.

Class I: Residential

A vehicle gate operator (or system) intended for use in a

home of one to four single-family dwellings, or a garage or

parkingareaassociatedtherewith.

Class II: Commercial or General Public Access

A vehicular gate operator (or system) intended for use in a

commerciallocationorbuildingsuch asamulti-familyhous-

ingunit(five or more single-family units), hotel,garage,re-

tailstore,orother building servicing the general public.

Class III: Industrial or Limited Access

Avehiculargateoperator(orsystem)intendedfor use in an

industrial location or building such as a factory or loading

dockareaorother locations notintendedtoservicethe gen-

eralpublic.

ClassIV: RestrictedAccess

A vehicular gate operator (or system) intended for use in a

guarded industrial location or building such as an airport

security area or other restricted access locations not ser-

vicing the general public, in which unauthorized access is

preventedviasupervisionbysecuritypersonnel.

Model VS-GSLG is intended for Class III and IV applica-

tions only.

09-05-13

The following contact or non-contact obstruction

detection devices have been approved for use

with OSCO slide gate operators as part of a UL325

compliant installation:

ContactEdges:

MillerModels*:MG0-20,MGR-20,MGS-20,andME-120

Photoeyes:

2520-441 MMTCModelIR-55photoeye,165’ with

mountinghardware

2520-031 MMTC Model E3K photoeye, 28’ with

mountinghardware

*for OSCO part numbers, contact a sales representative for details

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 4 -- 4 -

- 4 -- 4 -

- 4 -

UNPACKINGANDINSPECTIONUNPACKINGANDINSPECTION

UNPACKINGANDINSPECTIONUNPACKINGANDINSPECTION

UNPACKINGANDINSPECTION

Beforeunpackingcheckthecartonfor exterior damage. If you find damage advise the deliverer of a potential claim.

Ifanyof the following partsaremissingfromthe carton, immediately notify your supplier. Claims for shortageswillbehonored

for only 30 days from the date of shipment:

(1) VS-GSLGOperator (1) HardwareBagContaining:

(1) Chain in Box (2) #50Master Link

(1) HardwareBoxContaining: (16) 3/8" Hex Nuts

(2) Gate Brackets (16) 3/8" Lock Washers

(4) 3" U-Bolts (16) 3/8" Flat Washers

(4) 4" U-Bolts (2) Springs(heavy)

(2) 3/16" Side Plates (4) 1/2" Hex Nuts

(2) 1/2" Side Plates (2) 1/2" Flat Washers

(2) 1/2" Chain Bolts (4) 3/8"-16 x 3/4" Square Head Set Screw

PRE-INSTALLATIONINFORMATIONPRE-INSTALLATIONINFORMATION

PRE-INSTALLATIONINFORMATIONPRE-INSTALLATIONINFORMATION

PRE-INSTALLATIONINFORMATION

Beforeinstallingthe VS-GSLG, read this manual completely to ensureallrequirementsforproperinstallationarepresent.

Verify that the voltage to be used matches thevoltage oftheoperator.

IMPORTANT: The gate must operate properly to assure trouble-free installation. Before installing the gate operator to the

gate,makesurethegate’sslideisfreeandunobstructed.Ifthegate doesn’t seem to operate properly,itmay

affecttheoperatorperformanceor greatly shorten the life of the unit.

INSTALLATIONINSTRUCTIONSINSTALLATIONINSTRUCTIONS

INSTALLATIONINSTRUCTIONSINSTALLATIONINSTRUCTIONS

INSTALLATIONINSTRUCTIONS

NOTE: Theseinstructionsareforanoperatorontherightsideoftheopening,whenviewedfromtheinside looking out. Left-

hand installation is simply transposed.

LOCATING AND INSTALLING POSTSLOCATING AND INSTALLING POSTS

LOCATING AND INSTALLING POSTSLOCATING AND INSTALLING POSTS

LOCATING AND INSTALLING POSTS

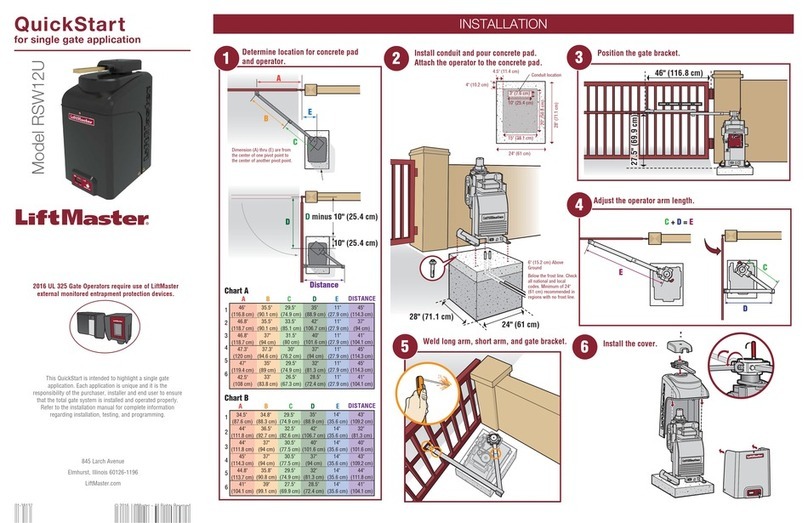

Locate and secure two galvanized posts (3" ID, 3 1/2" OD; see

drawing #2700-152). Embed the posts in concrete to a depth

required by local code or below the frost line.

OPERATOR INSTALLATIONOPERATOR INSTALLATION

OPERATOR INSTALLATIONOPERATOR INSTALLATION

OPERATOR INSTALLATION

Attach the operator to the posts using the U-Bolts and side

platesprovided(seedrawing#2700-223).Theoperatorcanbe

adjustedverticallytosuit;12"to 18" from the bottom of the idler

sprockets(chainline)wouldbe normal.Seedrawing#2700-152

foradditionalinstallationinformation.

CHAIN BRACKET INSTALLATIONCHAIN BRACKET INSTALLATION

CHAIN BRACKET INSTALLATIONCHAIN BRACKET INSTALLATION

CHAIN BRACKET INSTALLATION

Slide the gate to the fully closed position. Secure the chain

bracketontheverticalpostofthebackframewiththechain bolt

level with the bottom of the idler sprockets.

Slide the gate to the fully open position and secure the front

chainbracketon the front vertical post of the gate. Onceagain,

the chain bolt hole should be level with the bottom of the idler

sprockets.

Drawing #2700-223

5-03-3

ASEPARATE PEDESTRIAN GATE IS

REQUIREDFORALLPEDESTRIAN TRAFFIC.

THIS GATE MUST BE AMINIMUM DISTANCE

OFSEVEN(7)FEETFROM THE VEHICULAR

GATEAND THE GATE OPERATOR

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 5 -- 5 -

- 5 -- 5 -

- 5 -

IMPORTANT

A. Power supply must be of correct voltage and phase.

B. Always disconnect power from operator before servicing.

C. Keep clear of gate during operation.

ELECTRICAL INSTRUCTIONSELECTRICAL INSTRUCTIONS

ELECTRICAL INSTRUCTIONSELECTRICAL INSTRUCTIONS

ELECTRICAL INSTRUCTIONS

You’llfindthecompleteelectricalcircuitprintinsidetheoperatorcover.Thepowersupplymustbeampleandnottaken from an

overloadedline,asfaultyoperationwillresult.Thesupplymustbeofcorrectvoltageand phase. For proper wire gauge, refer to

“Wiring Specifications” on Page 32.

Properthermalprotectionis supplied withtheoperator.Themotorcontainsathermaloverloadprotector (singlephase)toprotect

fromoverheatingthemotordue to overloadorhigh-frequencyoperation.

LIMIT SWITCH ADJUSTMENTLIMIT SWITCH ADJUSTMENT

LIMIT SWITCH ADJUSTMENTLIMIT SWITCH ADJUSTMENT

LIMIT SWITCH ADJUSTMENT

(For Right Hand Operation, Left Hand Opposite)

Refer to the photo on page 7 when following these instructions.

Adjustthelimitnutsbydepressingthedetentplateandturningthenutsinthedesireddirectionoftravel. To allow for additional

travel in the open direction, for instance, rotate the open limit nut so that it moves to the left on the shaft. To allow for greater

travel in the close direction, rotate the close limit nut so that it moves to the right on the shaft.

Special Notes for Setting Speeds using LSO-2 & LSC-2:

LimitswitchesLSO-2andLSC-2control when theoperatoracceleratestomaximumspeedanddecelerates to minimumspeed.

It is recommended that LSO-2 and LSC-2 are adjusted first* so the gate slows to near stop before hitting LSO-1 or LSC-1 as

thesewillapply the brake upon activation.

*Theseareadjusted by slightly loosening the two screws which holdtheminplaceandslidingtowardorawayfromthecenter

of the limit box. Care must be taken not to adjust too close to the center as the limit nut may travel past the switch and start

accelerating at the end of the cycle.

9-03-6

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 6 -- 6 -

- 6 -- 6 -

- 6 - 9-03-6

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 7 -- 7 -

- 7 -- 7 -

- 7 -

PICTUREOF FOUR SWITCH ROTARY LIMIT BOXPICTUREOF FOUR SWITCH ROTARY LIMIT BOX

PICTUREOF FOUR SWITCH ROTARY LIMIT BOXPICTUREOF FOUR SWITCH ROTARY LIMIT BOX

PICTUREOF FOUR SWITCH ROTARY LIMIT BOX

2520-453

ONRIGHTHAND, LSC-2

ONLEFTHAND,LSO-2

ONRIGHTHAND,LSO-2

ONLEFTHAND,LSC-2

ONRIGHTHAND, LSC-1

ONLEFTHAND,LSO-1

ONRIGHTHAND,

CLOSELIMITNUT

ONLEFTHAND,

OPENLIMITNUT

ONRIGHTHAND

OPENLIMITNUT

ONLEFTHAND,

CLOSELIMITNUT

ONRIGHTHAND,LSO-1

ONLEFTHAND,LSC-1

DETENTPLATE

REMOVE CARDBOARD BEFORE

ADJUSTINGORRUNNING OPERATOR!!

LSO-1ANDLSC-1CONTROLGATE

FULLOPENANDCLOSE

LSO-2ANDLSC-2CONTROLGATE

OPERATOR RAMP UPAND DOWN

(SEE PAGE 5)

9-03-6

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 8 -- 8 -

- 8 -- 8 -

- 8 -

CHAIN SUPPORTSCHAIN SUPPORTS

CHAIN SUPPORTSCHAIN SUPPORTS

CHAIN SUPPORTS

When necessary, due to the length of the gate and chain, chain supports should be added to the gate at equally spaced

distances to allow the chain to sag as little as possible. A bolt located one inch below the chain line should be adequate.

MANUALDISCONNECTMANUALDISCONNECT

MANUALDISCONNECTMANUALDISCONNECT

MANUALDISCONNECT

Usethemechanicalpartsexplodedview drawing on page26andmechanicalpartslistonpage 27 to locatetheshifterleverand

the locking lever on the VS-GSLG operator. They can be found at the center and to the left inside the operator cabinet. (The

handleof each has beenfinishedineasyto spot red firm-grip coating.)

Todisconnectthe unitformanualoperation,graspthe handleofthespring-loadedshifterleverandpullitdirectly towardyouuntil

the spring-loaded locking lever snaps into place behind it. This action disengages the pinned shifter block from the drive

mechanism and holds the block in the disengaged position.

To re-engage the operator, move the locking lever to the right, releasing the spring-loaded shifter lever to snap back into the

engagedposition.

TORQUE LIMITER ADJUSTMENTTORQUE LIMITER ADJUSTMENT

TORQUE LIMITER ADJUSTMENTTORQUE LIMITER ADJUSTMENT

TORQUE LIMITER ADJUSTMENT

Beforeadjustingthetorquelimiter,makesurethegateis in goodworkingcondition.Onepersonshouldbe abletomovethegate

byhand.Be certain the gate moves freely and withoutbindingthroughoutitsentiretravel.

The torque limiter is set light at the factory. It must be adjusted during installation and checked on a regular basis.

NOTE:Thetorquelimitershouldbesettightenough so that whentheoperatorstartsthetorquelimiterdoesnotslip, but loose

enough to slip if the gate is obstructed.

TURN OFF POWER TO THE

OPERATOR BEFORE

MAKING ADJUSTMENTS!

1. Loosen the set screw on the the adjustment nut.

2. To increase the output, turn the adjustment nut clock-

wiseoneflat,or 1/6 turn, at a time until desired output is

obtained.

WARNING: Do not overtighten.The torque limiter must

slip if the gate is obstructed.

To reduce the output, turntheadjustmentnutcounter-

clockwise one fIat, or 1/6 turn, at a time until desired

outputisobtained.

NOTE: A properly adjusted torque limiter will not slip

duringnormaloperation.

3. Retighten the set screw on the adjustment nut.

ADJUSTMENT NUT

SETSCREW

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 9 -- 9 -

- 9 -- 9 -

- 9 -

MAINTENANCEMAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE

IMPORTANT

A. Power supply must be of correct voltage and phase.

B. Always disconnect power from operator before servicing.

C. Keep clear of gate during operation.

GENERALGENERAL

GENERALGENERAL

GENERAL

OSCOgateoperatorsaredesigned for manyyearsoftrouble-freeoperationand, under normaloperatingconditions,willrequire

onlyminimalmaintenance.

To ensure that your unit is ready for operation at all times — and to preclude serious damage or failure — inspect the unit

systematically. Proper adjustments and lubrication should bemadeasrecommended.

LUBRICATIONLUBRICATION

LUBRICATIONLUBRICATION

LUBRICATION

BEARINGS.Pillowblock bearings are equipped with fittings andshouldbelubricatedtwiceeachyear.

MOTOR. Motorshavesealedball bearings anddonotrequirefurtherlubrication. Ifbearingnoisedevelopsafterseveral yearsof

operation,bearingsshouldbereplaced.

DRIVE CHAINAND SPROCKET. Themaindrivechainandsprocketsshouldbeinspected,cleaned,andlightlyoiledeverysix

months. Do not oil chains inside the operator.

12-MONTH PREVENTATIVE MAINTENANCE12-MONTH PREVENTATIVE MAINTENANCE

12-MONTH PREVENTATIVE MAINTENANCE12-MONTH PREVENTATIVE MAINTENANCE

12-MONTH PREVENTATIVE MAINTENANCE

1. Check clutch for correct tension every 12 months.

2. Inspect clutch disc for wear every 12 months.

3. Check limit switches for adjustment and wear.

4. See that all nuts and bolts are tight.

5. Checkoillevelin gear reducer every 12 months. Fillup

with#90/140oil.

6. Checkchaintensionofmaindrivechainevery 6

months. Chain must be taut (not overly tight).

7. Cleanandlubricatemaindrivechainandsprockets

every 6 months using 40W oil. Do not use heavy

grease in cold climates.

DISCONNECT POWER FROM THEDISCONNECT POWER FROM THE

DISCONNECT POWER FROM THEDISCONNECT POWER FROM THE

DISCONNECT POWER FROM THE

OPERATOR BEFORE SERVICING!!!OPERATOR BEFORE SERVICING!!!

OPERATOR BEFORE SERVICING!!!OPERATOR BEFORE SERVICING!!!

OPERATOR BEFORE SERVICING!!!

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 10 -- 10 -

- 10 -- 10 -

- 10 -

Auto Close Timer Adjustment: This 270-degree adjustable potentiometer will signal the operator to close automatically,

providednoopen,reversingor obstruction signalsarepresentfromthefully-openposition. This timerisadjustablefrom0to124

seconds. This feature is turned on or off using dip switch #1.

Maximum Run Timer Adjustment: This270-degree adjustable potentiometer will signaltheoperatortostop running once it

counts down, unless a limit switch is reached or an input is received first. Each time the motor starts, this timer will begin

counting. This timer is adjustable from 15 to 100 seconds. If the timer expires, the unit locks out and the emergency alarm

sounds.

Open Direction Current Sense Adjustment: This multiturn potentiometer is used to calibrate the built-in current sensing

featurefordetectionofobstructionswhile running in the open direction.

Close Direction Current Sense Adjustment: This multiturn potentiometer is used to calibrate the built-in current sensing

featurefordetectionof obstructions while running in the closed direction.

Master/Slave Connection Block: Thisterminalblockisusedinconjunctionwithtwooperatorstoconfiguretwogatestoopen

andclosetogether.

Dip Switches:

#1 This switch turns the auto close timer off/on.

#2 This switch is used in conjunction with alarms and flashing lights that may be added to the operator. When the switch is

intheON position, these devices will start approximately two seconds priortotheoperatorstarting.IntheOFF position,

thedeviceswill only work while the operator isrunning.

#3 This switch is used in conjunction with single-button controls and radio receivers. In the ON position, successive inputs

will cause signals in the order of OPEN-STOP-CLOSE-STOP. In the OFF position, inputs will cause an OPEN signal

unless the gate is fully open, in which case it will signal CLOSE.

#4 Thisswitchdeterminesright-handvs. left-handbehavior.Whenlookingfrom insidetheprotectedareatowardthe gate,the

sideofthedrivetheoperatorison determines its handofoperation.IntheOFF position,theoperatorisset for right-hand.

#5 When turned ON, this switch will allow a one-second delay for solenoid locks to unlock before the motor starts.

#6 In the ON position the reverse delay is three (3) seconds. In the OFF position the reverse delay is one and a half (1 1/2)

seconds.

#7 Not used at this time.

#8 This switchisusedtosetMaster/Slave configuration. Operators which arestand-aloneormasterunitsshould be set to

OFF, while only slave units should have this switch set to ON.

CONTROLBOARDADJUSTMENTSCONTROLBOARDADJUSTMENTS

CONTROLBOARDADJUSTMENTSCONTROLBOARDADJUSTMENTS

CONTROLBOARDADJUSTMENTS

NOTE:DONOTFORCE270-DEGREEPOTENTIOMETERS

BEYONDTHEIRNORMALRANGEOFMOTION

ORDAMAGEMAYRESULT!

Control Board

with AC

Motor Board

DIAGNOSTIC

L.E.D.s

TERMINAL STRIP #2

CONNECTOR

TERMINAL STRIP #1

CONNECTOR

LIMIT SWITCH

CONNECTOR

LIMIT SWITCH

L.E.D.s

3A Fuse

2A Fuse

12-04-11

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 11 -- 11 -

- 11 -- 11 -

- 11 -

You must follow all required safety precautions and instructions at all times. Review the safety brochure

included with the operator. If any pages are missing or unreadable, contact OSCO at 1-800-333-1717 to request

additional copies.

Never connect a button station within reach of the gate or on the side of the gate operator.

Do not adjust the circuit board current sensing feature too high. It should be adjusted high enough to keep the

gate from falsely triggering the sensing, but no higher than necessary for the gate to operate. Do not defeat the

purpose of this function!

TERMINALCONNECTIONDESCRIPTIONSTERMINALCONNECTIONDESCRIPTIONS

TERMINALCONNECTIONDESCRIPTIONSTERMINALCONNECTIONDESCRIPTIONS

TERMINALCONNECTIONDESCRIPTIONS

TERMINALS FUNCTION DESCRIPTIONOFFUNCTION

24VAC 24VAC Provides24VoltAC power for accessories.

24VAC N Note: DC models will NOT have 24Volt AC power available.

24VDC+ 24VDC Provides24VoltDCpowerforaccessories.

24VDC-COMM.

1 & 4 OPEN Openstheoperator. Several accessories such as button stations,keypads,trans-

mitters and card readers can be wired to open.

3 & 4 CLOSE Closestheoperator. Use caution when wiring accessories to these terminals. The

gate must be clearly visible from the location of any accessories wired to

close.

4 & 5 SINGLE-BUTTON Performs the single-button function which will alternatebetweenopenandcloseor

open, stop and close - depending on dip switch #3. (See page 10 for details.)

2 & 4 STOP Stops the operator. If no stop button is used, a jumper is required across 2&4.

4 & 6 REVERSE Thisfunction will cause a reversalwhenthegateis traveling closed and willtravel

backtothe fully open position. Loop detectors are often wiredforreverse.

4 & 50 OPEN This function works only while the operator is opening. Any signal to this function

will cause the gate to stop, reverse a short distance, and then stop again. At this

time the auto close timer is disabled, and a renewed input will be required to start

the gate again. Should the gate be restarted and the signal occur again prior to

reaching a limit, the gate will stop again, and this time will sound the emergency

alarm and lock out.

4 & 51 CLOSE Thisfunctionworks exactly like the OPEN OBSTRUCTION, except that it willonly

work in the closing direction.

4 & 11 SHADOW/HOLD Thisfunctionwillkeep the gate in its fully open position while thesignalispresent.

Thisistypicallyusedwithaloopandloopdetectortokeepalargeswing gate open

whilevehiculartrafficispassingthrough.

24VDC+& 60 RUN/PRE-START A24VoltDCdevicesuchasastrobelightoralarmcanbewiredtotheseterminals.

Depending on dip switch #2, these devices will either begin three seconds before

the operator starts, or only while the motor is running. (See page 10 for details.)

OBSTRUCTION

OBSTRUCTION

12-04-11

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 12 -- 12 -

- 12 -- 12 -

- 12 -

CURRENTSENSINGADJUSTMENTSCURRENTSENSINGADJUSTMENTS

CURRENTSENSINGADJUSTMENTSCURRENTSENSINGADJUSTMENTS

CURRENTSENSINGADJUSTMENTS

Because gates vary in construction and may have different force requirements in the open and close directions to move, the

OSCO control board has separate Multi-turn potentiometers for adjusting in both directions independently. The adjustment

shouldbesetlightenoughtomaintainminimalforce (50-75 lbs.) should an obstruction occur,buthighenoughtokeepthegate

movingundernormalconditionswithoutinterruption.

Priortoadjustingtheoperatorcurrentsensingfunctions,makesurethegatemovesfreelyinbothdirections.Abadlyalignedor

poorlymaintainedgatemay cause false triggeringofthecurrentsensor.Refertopage10 whenfollowingtheinstructionsbelow.

Afactory adjustment tool has been supplied to make these adjustments easier. This tool has been taped to the control box for

yourconvenience. CLOSEDIRECTIONCURRENTSENSEADJUSTMENTCLOSEDIRECTIONCURRENTSENSEADJUSTMENT

CLOSEDIRECTIONCURRENTSENSEADJUSTMENTCLOSEDIRECTIONCURRENTSENSEADJUSTMENT

CLOSEDIRECTIONCURRENTSENSEADJUSTMENT

When the gate operator leaves the factory, it has been preset for a relatively light gate function and will require additional

adjustment.Begin by starting the gategoingclosed.Ifthe operator stops andreverses,turntheclose direction potentiometer

(seepage10)oneturnhigher,pressthe STOP button,andtryagain.Repeatthisprocessuntilthegatenolonger causes false

trippingofthecurrentsensor. Note that each time the gate operator reverses,the STOPbuttonmustbepressed.Next,turnthe

close direction potentiometer lower slowly while the operator is running the gate closed until the gate operator stops and

reverses again. From this point, turn the close direction potentiometer higher by 1 1/2 turns for all 115 VoltAC and 24 Volt DC

operators,andby3/4ofaturnhigherforall230VoltACoperators.Additional fine adjustment by 1/4 turns may be necessary to

eliminatefalsetriggering.

OPENDIRECTIONCURRENTSENSEADJUSTMENTOPENDIRECTIONCURRENTSENSEADJUSTMENT

OPENDIRECTIONCURRENTSENSEADJUSTMENTOPENDIRECTIONCURRENTSENSEADJUSTMENT

OPENDIRECTIONCURRENTSENSEADJUSTMENT

Repeatthesameprocesswiththeopendirectionpotentiometerwhilerunningthegateintheopendirection.Oncethisisdone,

run the gate through several complete cycles and make sure the gate does not false trip in either direction.

MAXIMUMRUNTIMERADJUSTMENTMAXIMUMRUNTIMERADJUSTMENT

MAXIMUMRUNTIMERADJUSTMENTMAXIMUMRUNTIMERADJUSTMENT

MAXIMUMRUNTIMERADJUSTMENT

Thisadjustablepotentiometersetsthemaximumlengthoftimethemotorwillrunbeforeshuttingdown.Itshouldbeconfigured

for the time it takes to run the gate fully open or closed, plus an additional 15 seconds. See page 10 for details.

AUTOCLOSETIMERADJUSTMENTAUTOCLOSETIMERADJUSTMENT

AUTOCLOSETIMERADJUSTMENTAUTOCLOSETIMERADJUSTMENT

AUTOCLOSETIMERADJUSTMENT

This adjustable potentiometer sets the length of time which elapses before the gate operator automatically closes the gate, from

the fully open position, provided no open, reversing, or obstruction signals are present. This feature can be turned on or off via dip

switch selection. See page 10 for details.Do not use the auto close timer without an appropriate reversing device

installed!

MASTER/SLAVECONNECTIONMASTER/SLAVECONNECTION

MASTER/SLAVECONNECTIONMASTER/SLAVECONNECTION

MASTER/SLAVECONNECTION

Athree-wire shielded conductor cable is required to connect master and slave operators. You must use Belden 8760Twisted

Pair Shielded Cable(orequivalent) only – OSCO part number 2500-1982, per foot). See page 10 for details of this connection,

as well as dip switch selection. Note: The SHIELD wire should be connected in both the master and slave operators. In addition, you

must run power to both the master and slave operators.

Multi-turn Potentiometer

Remember it is important not to set the adjustment

too high! Doing so will defeat the purpose of the cur-

rent sensing as an obstruction detecting feature.

12-04-11

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 13 -- 13 -

- 13 -- 13 -

- 13 - 5-03-3

ONBOARDL.E.D.INDICATORDESCRIPTIONSONBOARDL.E.D.INDICATORDESCRIPTIONS

ONBOARDL.E.D.INDICATORDESCRIPTIONSONBOARDL.E.D.INDICATORDESCRIPTIONS

ONBOARDL.E.D.INDICATORDESCRIPTIONS

Control Board L.E.D. Indicators:

OPEN This indicator is lit when an open signal is present. This signal can come from such devices as button

stations, radio receivers, keypads and telephone entry systems.

CLOSE This indicator is lit when a closed signal is present. This signal typically comes from three-button stations.

STOP This indicator is lit when there is a break in the stop circuit. Make sure there is a stop button wired in and

workingproperly.

SINGLE This indicator is lit when a signal from a single-button station or radio receiver is present.

CLOSEOBST Thisindicatorislitwhen a close obstruction signalispresent.Thissignalcancome from edges and photo

eyes which have been wired to the close obstruction inputs.

OPENOBST This indicator is lit when an open obstruction signal is present. This signal can come from edges and

photoeyeswhich have been wired to the open obstructioninputs.

SAFETYLOOP This indicator is lit when a reversing signal is present. This signal is generated by a loop detector wired to

the safety loop terminals.

SHADOWLOOP Thisindicatoris lit when a shadow/holdopensignalispresent. This signal is generatedbyaloopdetector

wiredtothe shadow loop terminals.

Thisindicatorislitwhentheopen#1 limit switch is activatedonaright-handoperator,ortheclose#1switch

on a left-hand. If this indicator is lit and the gate is not in its full open/closed position, the limit may need

adjusting or the limit switch may need replacing.

Thisindicatorislitwhentheopen#2 limit switch is activatedonaright-handoperator,ortheclose#2switch

onaleft-hand.

Thisindicator is lit whentheclose#1limit switch is activatedonaright-handoperator, or the open#1ona

left-hand. If this indicator is lit and the gate is not in its full open/closed position, the limit may need

adjusting or the limit switch may need replacing.

Thisindicatorislitwhentheclose#2 limit switch is activatedonaright-handoperator, or the open#2switch

onaleft-hand.

Motor Board L.E.D. Indicators:

NONLABELED One of thesetwoindicatorswillbelitwhenthemotorisrunningthegate open, and the other is lit when the

motor is running the gate closed.

BRAKEREL. This indicator is lit when the brake is NOT applied.

LSO-1

LSO-2

LSC-1

LSC-2

LSC-1

LSC-2

LSO-1

LSO-2

LH RH

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 14 -- 14 -

- 14 -- 14 -

- 14 -

IMPORTANTNOTESFORIMPORTANTNOTESFOR

IMPORTANTNOTESFORIMPORTANTNOTESFOR

IMPORTANTNOTESFOR

INSTALLATIONOFMASTER/SLAVEAPPLICATIONSINSTALLATIONOFMASTER/SLAVEAPPLICATIONS

INSTALLATIONOFMASTER/SLAVEAPPLICATIONSINSTALLATIONOFMASTER/SLAVEAPPLICATIONS

INSTALLATIONOFMASTER/SLAVEAPPLICATIONS

When setting up Master/Slave gate operators, it is best to make adjustments and run each operator individually. To do this,

simply:

a. SetDipSwitch#4toproperhandofoperation(right-handorleft-hand)

b. Set Dip Switch #8 as Master (off)

Runeachoperatormaking current sensing adjustmentsasnecessary, as indicated on the Control BoardAdjustmentspageof

this installation guide. When both operators have been adjusted, turn power off, then turn on Dip Switch #8 in the operator

chosenas the Slave.

Thetimerto close and radio/single button behavior are setintheMasteroperator.

Thefollowingselectionsaresetindividually:

CurrentSensing

MaximumRunTimer

One-SecondLockRelease

Three-SecondPre-StartWarning

Right/Left-HandSelections

SURGEPROTECTORINSTRUCTIONSSURGEPROTECTORINSTRUCTIONS

SURGEPROTECTORINSTRUCTIONSSURGEPROTECTORINSTRUCTIONS

SURGEPROTECTORINSTRUCTIONS

The optional surge protector should be connected

to any inputs that have an accessory connected to

it. This includes the 3-button station, so it must be

connected to 1, 2A and 3 in all cases. The green

wire connected to ground, which is electrically the

same as terminal 4. The red wires connect to

terminals 2A and 24VDC+. This will cause the

2 amp fuse to blow if this section of the module

becomes shorted. With any of the other inputs

connectedto the surge protector, if their protection

linebecomesshortedduetoasurgeover the rating

of the module, the corresponding LED on the main

board will remain lit, causing a constant signal to

the controller. If this is found, please replace the

entiresurge protector with anewunit.

Do not simply unhook the shorted wire, as this

removestheprotectionfrom the circuit thatwas

saved by the protector in the first place!

8-03-5

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 15 -- 15 -

- 15 -- 15 -

- 15 - 5-03-3

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 16 -- 16 -

- 16 -- 16 -

- 16 - 11-03-7

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 17 -- 17 -

- 17 -- 17 -

- 17 - 5-03-3

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 18 -- 18 -

- 18 -- 18 -

- 18 -

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONSCONTROLandACCESSORYCONNECTIONILLUSTRATIONS

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 19 -- 19 -

- 19 -- 19 -

- 19 - 5-03-3

LOOP LAYOUT ILLUSTRATIONLOOP LAYOUT ILLUSTRATION

LOOP LAYOUT ILLUSTRATIONLOOP LAYOUT ILLUSTRATION

LOOP LAYOUT ILLUSTRATION

Referto Connection Descriptions on page 11and LoopAccessory Connectionsonpage18fordetails.

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDEVS-GSLG OPERATOR INSTALLATION GUIDE

VS-GSLG OPERATOR INSTALLATION GUIDE

- 20 -- 20 -

- 20 -- 20 -

- 20 - 5-03-3

EDGELAYOUTILLUSTRATION#1EDGELAYOUTILLUSTRATION#1

EDGELAYOUTILLUSTRATION#1EDGELAYOUTILLUSTRATION#1

EDGELAYOUTILLUSTRATION#1

RefertoConnection Descriptions on page11andContactEdgeConnectionsonpage17fordetails.

Table of contents

Other OSCO Gate Opener manuals

Popular Gate Opener manuals by other brands

Chamberlain

Chamberlain RSW12U quick start guide

SOMFY

SOMFY Ixengo L 24V installation instructions

Viking Access Systems

Viking Access Systems E-4 Installation instructions and safety information

Roger Technology

Roger Technology MONOS4/220 INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

GTO

GTO SW-2000XL Brochure & specs

Beninca

Beninca DU.IT14N Operating instructions and spare parts catalogue

Porta

Porta KIS100 installation manual

Viking

Viking R-6 Installation Instructions and Use & Care Guide

Chamberlain

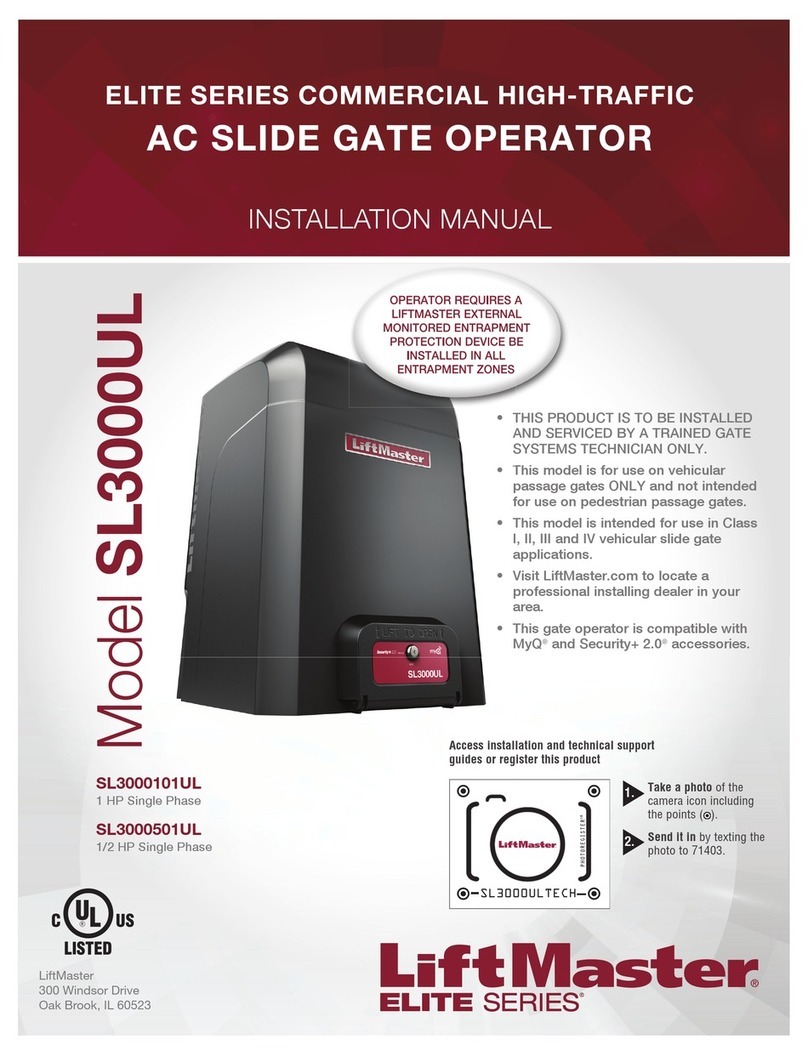

Chamberlain Liftmaster SL3000101UL installation manual

Chamberlain

Chamberlain LA400 Installation and operation manual

CAME

CAME BKV2000P Quick setup guide

BFT

BFT PHOBOS N BT installation manual