OSCO GSLG-A User manual

GSLG-A

INSTALLATION GUIDE

June 2003, Rev. 11

UL325 COMPLIANCE REQUIRES THE USE OF CONTACT EDGES

OR PHOTOELECTRIC CONTROLS ON ALL AUTOMATIC OR

REMOTELY-CONTROLLED GATE OPERATORS.

OPERATORSPECIALTYCOMPANY,INC.

CASNOVIA, MI 49318 • U.S.A.

®

GSLG-A OPERATOR INSTALLATION GUIDE

- 2 -

TABLEOFCONTENTS

PRE-INSTALLATIONINFORMATION

GateOperatorClassifications ......................................................................................................................................3

SafetyInformation and Warnings .................................................................................................................................3

Pre-InstallationInformation ...........................................................................................................................................3

Warranty......................................................................................................................................................................3

INSTALLATION

WiringSpecifications ...................................................................................................................................................4

PostMounting Instructions ..........................................................................................................................................5

Gate Bracket and Chain Assembly Instructions ...........................................................................................................6

Vent PlugInstallation ...................................................................................................................................................7

TorqueLimiterAdjustments..........................................................................................................................................7

ElectricalConnection and Adjustments........................................................................................................................8

Limit Nut Adjustments .................................................................................................................................................8

CONTROLBOARD ADJUSTMENTSand ACCESSORYCONNECTIONS

ControlBoardAdjustments ..........................................................................................................................................9

TerminalConnection Descriptions ..............................................................................................................................10

CurrentSensingAdjustments ....................................................................................................................................11

CloseDirectionCurrentSense Adjustment ................................................................................................................ 11

OpenDirectionCurrentSenseAdjustment.................................................................................................................11

Maximum RunTimer Adjustment ............................................................................................................................... 11

AutoCloseTimer Adjustment .................................................................................................................................... 11

Master/SlaveConnection ........................................................................................................................................... 11

OnboardL.E.D.IndicatorDescriptions .......................................................................................................................12

ImportantNotesforInstallationofMaster/SlaveApplications......................................................................................13

ControlandAccessory Connection Illustrations ....................................................................................................14-17

ILLUSTRATIONS

LoopLayoutIllustration ..............................................................................................................................................18

EdgeLayoutIllustration#1.........................................................................................................................................19

EdgeLayoutIllustration#2.........................................................................................................................................20

PhotoEye Illustration.................................................................................................................................................21

Picket Gate Illustration ..............................................................................................................................................22

TrackGateIllustration................................................................................................................................................23

TROUBLESHOOTING ...................................................................................................................................................24

PARTS LISTS

HowtoOrderReplacementParts...............................................................................................................................24

ModelGSLG-A Mechanical Parts Exploded View ......................................................................................................25

Model GSLG-A Mechanical Parts List .......................................................................................................................26

Model GSLG-A Single Phase Control Box Exploded View and Parts List ..................................................................27

Model GSLG-A Three Phase Control Box Exploded View and Parts List ...................................................................28

PREVENTATIVEMAINTENANCE ..................................................................................................................................30

GATE OPERATORINSTALLATION CHECKLIST ..........................................................................................................32

CAUTION!

DO NOT INSTALL

CONTROLSON A

GATE ORFENCE LINE

CAUTION!

ONLY QUALIFIEDSERVICE

TECHNICIANSSHOULD

WORK ON AN OSCO

SLIDEGATEOPERATOR

CAUTION!

DO NOT INSTALL

CONTROLS

ONTHE OPERATOR

GSLG-A OPERATOR INSTALLATION GUIDE

- 3 -

Read the following before beginning to install OSCO slide

gate operators:

1. Readtheyellow “Safety Instructions” brochure enclosed

with the packet of information. If you do not have one,

pleasecallOSCOat1-800-333-1717torequestone. Read

andfollow all instructions.

2. All electrical connections to the power supply must be

made by a licensed electrician and must observe all

national and local electrical codes.

3. A separate power-disconnect switch should be located

neartheoperatorsothatprimarypowercanbeturnedoff

whennecessary.

4. Install the enclosed warning signs on both sides of the

gate. Each sign must be plainly visible from the side of

the gate on which they are mounted.

5. Never reach between, through or around the fence to

operatethegate.

6. You must install all required safety equipment.

GATEOPERATOR

CLASSIFICATIONS

PRE-INSTALLATIONINFORMATION

Before unpacking, inspect the carton for exterior damage. If

youfinddamage,advisethedeliverycarrierofapotentialclaim.

Inspect your package carefully. You can check your acces-

sory box parts with the enclosed packing slip for your conve-

nience.Claimsforshortages will be honored for only 30 days

fromthe date of shipment.

Before installing the operator, read this manual completely

toensureall requirements for proper installationarepresent.

Verify that the voltage to be used matches the voltage of the

operator.

SAFETYINFORMATION

ANDWARNINGS

IMPORTANT!!

Beforeinstallingthegateoperator,makesurethegate’sslide

isfreeandlevelthroughouttheentireopeningdistance.If the

gate does not seem to operate properly, it may affect the op-

erator performance or greatly shorten the life of the unit. The

gate should be designed so that airflow through the fabric is

ampletopreventwindresistance and drag.

All gate operators can be divided into one of four different

classifications,dependingon their design and usage.

Class I: Residential

A vehicle gate operator (or system) intended for use in a

home of one to four single-family dwellings, or a garage or

parkingareaassociatedtherewith.

Class II: Commercial or General Public Access

A vehicular gate operator (or system) intended for use in a

commerciallocation or buildingsuchasa multi-family hous-

ingunit (five or more single-familyunits), hotel, garage, re-

tailstore,or other building servicing thegeneralpublic.

Class III: Industrial or Limited Access

Avehicular gate operator (or system) intended for use in an

industrial location or building such as a factory or loading

dockarea orotherlocationsnot intended toservicethe gen-

eralpublic.

ClassIV: Restricted Access

A vehicular gate operator (or system) intended for use in a

guarded industrial location or building such as an airport

security area or other restricted access locations not ser-

vicing the general public, in which unauthorized access is

preventedvia supervision by securitypersonnel.

The following contact or non-contact obstruction

detection devices have been approved for use with

OSCO slide gate operators as part of a UL325 com-

pliant installation:

2510-264 EMX Model IRB-325 photo eye 60’ with

mountinghardware

2520-031 MMTC Model E3K photo eye, 28’ with

mountinghardware

2520-178 5’ Miller Edge MG020 with transmitter

2520-134 5’ Miller Edge MG020 with coil cord

2510-163 4’ Miller Edge MG020 with coil cord

2520-246 5’ Miller Edge MGR20 with coil cord

2520-271 5’ Miller Edge MGS20 with coil cord

LIMITED TWO-YEAR WARRANTY

Thiselectric operator is warranted fora period of two (2)

years from date of sale against defects in materials or

workmanship. Defective part(s) shall be repaired or re-

placed at no charge, at the manufacturer’s option. All

accessoriesarecoveredbytheirmanufacturer’swarranty.

The manufacturer will not be responsible for trans-

portation and/or field service charges.

The above warranty is in lieu of all other warranties, ex-

pressedor implied, and shall be considered void ifvisible

evidence implies recommended installation procedures

andmaintenanceinstructionswerenotfollowed,or if the

electricoperator was not sized appropriatelyforthe par-

ticular installation.

GSLG-A OPERATOR INSTALLATION GUIDE

- 4 -

USE COPPER WIRE ONLY! ACCESSORY WIRING

All Models

24VDC

*Over 350 ft. use DC power.

0-2000

14

24VAC

250

350*

14

12

Volts

Maximum

Distance (ft.)

Wire

Gauge

1. Select from the chart at the bottom of this page corresponding to the

model, voltage and horsepower rating of your operator.

2. The distance shown on the chart is measured in feet from the opera-

tor to the power source. DO NOT EXCEED THE MAXIMUM DIS-

TANCE. These calculations have been based on standard 115V and

230V supplies with a 10% drop allowable. If your supply is under the

standard rating, the runs listed may be longer than what your appli-

cation will handle, and you should not run wire too near the upper

end of the chart for the gauge of wire you are using.

3. When large-gauge wire is used, a separate junction box (not sup-

plied) may be needed for the operator power connection.

4. All control devices are now 24VDC, which can be run considerable

distances. 24VAC is available for other devices, such as loop detec-

tors and photo eyes.

5. Wire run calculations are based on the National Electrical Code, Ar-

ticle 430 and have been carefully determined based on motor inrush,

brake solenoids, and operator requirements.

WIRINGSPECIFICATIONS

6. Connect power in accordance with local codes. The green ground

wire must be properly connected.

7. Wire insulation must be suitable to the application.

8. Control wiring must be run in a separate conduit from power wiring.

Running them together may cause interference and faulty signals in

some accessories.

9. Electrical outlets are supplied in all 115VAC models for convenience

with occasional use or low power consumption devices only. If you

choose to run dedicated equipment from these devices, it will de-

crease the distance for maximum run and the charts will no longer be

accurate.

10. A three-wire shielded conductor cable is required to connect master

andslave operators. Youmust use Belden8760 Twisted PairShielded

Cable (or equivalent) only – OSCO part number 2500-1982, per

foot). See page 9for details of this connection, as well as dip switch

selection. Note: The SHIELD wire should be connected in both

the master and slave operators

esahP3:gniriWrewoP

stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG

V8022/1 PH

2411 6181 0982

175 809 5441

2101

8

V0322/1 PH

4431 7312 0043

276 9601 0071

2101

8

V0642/1PH

1483 6016 2179

1291 3503 6584

2101

8

V802 4/3PH

029 4641 0332

064 237 5611

2101

8

V032 4/3PH

4801 3271 1472

245 268 1731

2101

8

V0644/3PH

9723 2125 1928

0461 6062 6414

2101

8

V802

PH1

417 6311 4081

753 865 209

2101

8

V032

PH1

048 6331 4212

024 866 2601

2101

8

V064

PH1

9862 4724 8976

5431 7342 9933

2101

8

MODEL GSLG-A – THREE PHASE

MODEL GSLG-A – SINGLE PHASE

gniriWrewoP

stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG stloV PH& ecnatsiDxaM lauDelgniS eriW eguaG

V511

2/1PH

222 453 665 009 0341

111 771 382 054 517

2101

8

6

4

V802

2/1PH

067 0021 4291 0603 4684

083 006 269 0381 2342

2101

8

6

4

V032

2/1PH

498 2241 4622 0063 4275

744 117 2311 0081 2682

2101

8

6

4

V511

4/3PH

871 282 054 617 0411

98 141 522 853 075

2101

8

6

4

802

4/3PH

406 859 6251 4242 6583

203 874 367 2121 8291

2101

8

6

4

V032

4/3PH

017 8211 6971 2582 8354

553 465 898 6241 9622

2101

8

6

4

V511

PH1

061 452 604 646 6201

08 721 302 323 315

2101

8

6

4

V802

PH1

445 468 4731 4812 6743

272 234 686 2901 8371

2101

8

6

4

V032

PH1

046 6101 6161 0752 0904

023 805 808 5821 5402

2101

8

6

4

12-02-8

GSLG-A OPERATOR INSTALLATION GUIDE

- 5 -

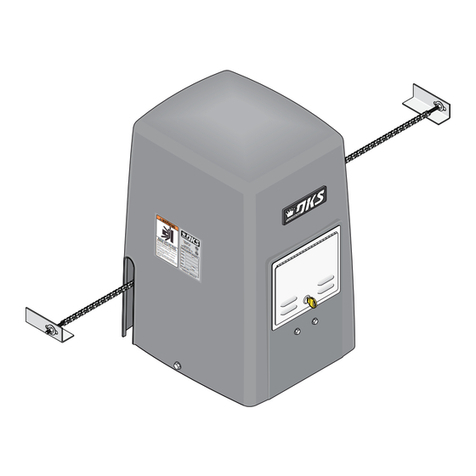

POST MOUNTING INSTRUCTIONS FOR MODEL GSLG-A

SIDEPLATEINSTALLATION

Before installing, make sure the gate rolls or slides freely,

and that all exposed rollers are properly covered. The gate

must be covered with fabric with openings no larger than

2 1/4” in size, to a minimum height of 48 inches from ground

level. On picket-style gates, if pickets are spaced less than

2 1/4” apart, mesh is optional.

Use two 3 - 3 1/2” OD galvanized posts and secure with

concrete footings as shown, length to be determined by

local codes, frost line depth and soil conditions. Secure the

operator to the posts using the 4” U-bolts, side plates, and

hardware. There are a total of eight side plates. There are

six 3/16” side plates which should be mounted on the

outside top and bottom of the cabinet, two 3/16” side plates

which go on the top inside and two 1/2” side plates which

should be mounted on the inside top of the cabinet as shown

in the illustration at the right.

To assemble the drive chain and gate brackets, refer to page

6. Make sure that the chain sag does not exceed recom-

mended sizes and that the chain does not come into contact

with the moving parts of the gate or ground.

For optional pad mounting instructions, see OSCO drawing

#2700-360.

ASEPARATE PEDESTRIAN GATE IS REQUIRED FOR ALL

PEDESTRIAN TRAFFIC. THIS GATE MUST BE A MINIMUM

DISTANCE OF 7 FEET FROMTHE VEHICULAR

GATE ANDGATE OPERATOR

08-01-3

GSLG-A OPERATOR INSTALLATION GUIDE

- 6 -

Assemble a gate bracket (1) to the front edge of the gate,

using two U-bolts (2), and mounting hardware (3). Before

tightening down completely, be sure the bracket is parallel

tothegate.Tighten the U-bolt hardware the rest of the way,

thenscrew thesquarehead bolts(4)intothe threadedholes

in the gate plate until they bottom out against the gate.

These will help keep the bracket from twisting on the pipe.

Slideathreadedchainpin (5)throughthe bracketasshown,

with spring (6), flat washer (10), and two hex nuts (7).

Attach one end of the drive chain (8) to the chain pin using

masterlink(9) and begin unrolling ittowardthe operator.

Removetheraincover fromtheback oftheslidegateopera-

tor.Carefully thread the drivechainunderthefirstidler,over

thedrivesprocket, and then under thelastidler. Makesure

youfeed most of the chain through thesprocketsforattach-

ing to the back end of the gate.

Assemble the other gate bracket on the rear edge of the

gate,usingthe same process as you didwith thefrontgate

bracket. Once this is done, take the other chain pin, spring

andjamnuts and assemble with theendof drive chain and

the other master link.

At this point you should be able to adjust the chain tension

bytighteningthejamnuts on each end. Approximately 1/4”

to 3/8” of slack per foot of drive chain is acceptable. Make

surethe chain does notdragontheground,across the gate

rollersortheidler frame of the operator.

Additional mounting holes have been provided in the gate

bracketfor installer convenience.

GATEBRACKETANDCHAINASSEMBLYINSTRUCTIONS

Numbered items in these

drawingsareforinstructional

referenceonly.Foractualpart

numbers,gotothe parts lists

in the back of this booklet.

GSLG-A OPERATOR INSTALLATION GUIDE

- 7 -

VENTPLUGINSTALLATION

Gearreducersusedin OSCO gate operators will have solidplugs installedpriortoshipmentin order to keep the oil insidefrom

spilling out during shipping. A vent plug has been provided to replace this plug during installation. This plug will look similar to

theonesshown below. Some modelsmayhave a vent plug with abreatherpin. This pin should beremovedafter installing the

operator.

OR

TORQUELIMITERADJUSTMENTS

Before adjusting the torque limiter, make sure the gate is in good

working condition. One person should be able to move the gate by

hand. Becertain the gatemovesfreelyand without binding through-

outits travel. Torquelimiters are set lightatthe factory and mustbe

adjustedduringinstallation.Adjustthetorquelimitertightenoughto

keepitfromslipping during normal operation.

To adjust the torque limiter in model GSLG-A

1. Loosen the setscrew in the adjustment nut.

2. To increase the output, turn the adustment nut clockwise one

flat, or 1/6 turn, at a time until desired output is obtained.

Toreducetheoutput,turntheadjustmentnut counterclockwise

one flat, or 1/6 turn, at a time until desired output is obtained.

3. Retighten the setscrew in the adjustment nut.

MODELGSLG-A

SETSCREW

ADJUSTMENT NUT

GSLG-A OPERATOR INSTALLATION GUIDE

- 8 -

ELECTRICALCONNECTIONANDADJUSTMENTS

All OSCO gate operators are supplied with a power disconnect switch to turn on and off the power supply available to the

operator. Incoming power should be brought into the operator and connected to the labeled pigtails in the disconnect box

following wiringspecifications on page 4.A wiring connections print canbefound on the inside coverofthe operator.

Properthermalprotectionissupplied withtheoperator.The motorcontainsa thermaloverloadprotectortoprotectfromoverheat-

ingthemotordue to overload or high-frequency operation. Thisoverloadwillautomaticallyreset after the motor cools down.

LIMITNUTADJUSTMENTS

Thelimit nuts are notpresetat the factory andmustbe adjusted for thelength of the gate theoperator is installed on.Thelimit

switches are activated by two threaded nylon rotary limit nuts which are attached to a threaded shaft and driven by chain and

sprocketsfrom the main drive shaft.Remove the cardboard filler beforeattempting to adjust the limitnuts.

With the gate connectedto the gate operatorin a mid-travel position, andthe power disconnect switchturned OFF, disconnect

theoperator by usingthemanualdisconnectlever. Instructions forthemanualdisconnectcan be foundintheindividualoperator

owner’s guides. Once the operator has been disconnected, manually move the gate by hand to within a foot of its fully open

position (the foot of distance is necessary to allow for coasting of the operator after the limit switch is tripped).

Once the gate is in this position, adjust the open limit nut until it activates the limit switch for open, LSO-1. Press down on the

detentplate and rotate thenutalong the threaded shaft.Refer to the illustrationbelowfor additional details.

Once the open limit nut is set, repeat the above process for the close direction nut and the LSC-1 limit switch.

Afterfinishingthe initial limit nut adjustments, reposition thegatetoapproximately its center of travel. Re-engage theoperator

andturn thepowerdisconnectON. Standclearofany moving partsandpressthe OPEN buttononthethree-button station.Ifthe

gate begins to close instead of open, press the STOP button immediately. Find the dip switch block on the main control board

and switch thehand of operation (dipswitch #4, seepage 9)andtrytoopenthegateagain.Observethegate as it runs through

acompletecycleinbothdirections,andadjust your limits again if necessary.Finelevelsofadjustmentcanalsobeachieved by

adjusting a few teeth on the nut at a time. If the gate stops in midtravel, the open or close current sensor adjustment or the

maximumrun timer may needadjustment (see page 11).

Power supply must be of correct voltage and phase.

Always disconnect power from operator before servicing.

Keep clear of gate during operation.

POWER DISCONNECT BOX

(115VAC VERSION SHOWN)

L1

(WHITE)

L2

(BLACK)

GROUND

(GREEN)

9-26-02

ONA RIGHT-HAND OPERATOR:

OPEN LIMIT SWITCH IS THE ONE CLOSER

TO THE FRONT OF THE OPERATOR. ON A

LEFT-HAND OPERATOR, THE OPEN LIMIT

SWITCH IS THE ONE FURTHEST AWAY

FROMTHE FRONT OF THE OPERATOR.

GSLG-A OPERATOR INSTALLATION GUIDE

- 9 -

CONTROLBOARDADJUSTMENTS

NOTE:DONOTFORCE270-DEGREEPOTENTIOMETERS

BEYONDTHEIRNORMALRANGEOFMOTION

ORDAMAGEMAYRESULT!

Control Board

with AC

Motor Board

DIAGNOSTIC

L.E.D.s

TERMINAL STRIP #2

CONNECTOR

TERMINAL STRIP #1

CONNECTOR

LIMIT SWITCH

CONNECTOR

LIMIT SWITCH

L.E.D.s

3A Fuse

2A Fuse

Auto Close Timer Adjustment: This 270-degree adjustable potentiometer will signal the operator to close automatically,

providedno open, reversing orobstructionsignalsarepresent from the fully-openposition.Thistimeris adjustable from 0to 124

seconds. This feature is turned on or off using dip switch #1.

Maximum Run Timer Adjustment: This270-degree adjustable potentiometer willsignal the operatorto stop running onceit

counts down, unless a limit switch is reached or an input is received first. Each time the motor starts, this timer will begin

counting. This timer is adjustable from 15 to 100 seconds. If the timer expires, the unit locks out and the emergency alarm

sounds.

Open Direction Current Sense Adjustment: This multiturn potentiometer is used to calibrate the built-in current sensing

featurefordetection of obstructions while running intheopendirection.

Close Direction Current Sense Adjustment: This multiturn potentiometer is used to calibrate the built in current sensing

featurefordetection of obstructions while runninginthe closed direction.

Master/Slave Connection Block: Thisterminalblock is used in conjunction with two operators toconfigure twogates toopen

andclosetogether.

Dip Switches:

#1 This switch turns the auto close timer off/on.

#2 This switch is used in conjunction with alarms and flashing lights that may be added to the operator. When the switch is

inthe ON position, these devices willstartapproximately two seconds prior totheoperator starting. In the OFF position,

thedevices will only work whilethe operator is running.

#3 This switch is used in conjunction with single-button controls and radio receivers. In the ON position, successive inputs

will cause signals in the order of OPEN-STOP-CLOSE-STOP. In the OFF position, inputs will cause an OPEN signal

unless the gate is fully open, in which case it will signal CLOSE.

#4 Thisswitchdetermines right-handvs.left-handbehavior. When lookingfrominside the protectedareatoward the gate,the

sideof the drive the operator is on determines its hand ofoperation.IntheOFF position,theoperatorissetfor right-hand.

#5 When turned ON, this switch will allow a one-second delay for solenoid locks to unlock before the motor starts.

#6 IntheON position, this switch willdisable the inherentDC brake in DC operators only.Inaddition,theR2brakeresistor

on the DC motor board must be cut from the board (refer to the picture above). In the OFF position, the DC brake will

function.

#7 Not used at this time.

#8 This switchis used toset Master/Slave configuration. Operatorswhich are stand-alone ormaster units should beset to

OFF, while only slave units should have this switch set to ON.

GSLG-A OPERATOR INSTALLATION GUIDE

- 10 -

You must follow all required safety precautions and instructions at all times. Review the safety brochure

included with the operator. If any pages are missing or unreadable, contact OSCO at 1-800-333-1717 to request

additional copies.

Never connect a button station within reach of the gate or on the side of the gate operator.

Do not adjust the circuit board current sensing feature too high. It should be adjusted high enough to keep the

gate from falsely triggering the sensing, but no higher than necessary for the gate to operate. Do not defeat the

purpose of this function!

TERMINALCONNECTIONDESCRIPTIONS

TERMINALS FUNCTION DESCRIPTIONOF FUNCTION

24VAC 24VAC Provides24Volt AC power for accessories.

24VAC N Note: DC models will NOT have 24Volt AC power available.

24VDC+ 24VDC Provides24VoltDCpower for accessories.

24VDC-COMM.

1 & 4 OPEN Openstheoperator. Several accessories suchasbuttonstations, keypads, trans-

mitters and card readers can be wired to open.

3 & 4 CLOSE Closestheoperator. Use caution when wiring accessoriestotheseterminals. The

gate must be clearly visible from the location of any accessories wired to

close.

4 & 5 SINGLE-BUTTON Performs the single-button function whichwillalternatebetweenopenandcloseor

open, stop and close - depending on dip switch #3. (See page 9for details.)

2 & 4 STOP Stops the operator. If no stop button is used, a jumper is required across 2&4.

4 & 6 REVERSE Thisfunction will cause a reversal when thegate is traveling closedand will travel

backtothe fully open position.Loopdetectors are often wired forreverse.

4 & 50 OPEN This function works only while the operator is opening. Any signal to this function

will cause the gate to stop, reverse a short distance, and then stop again. At this

time the auto close timer is disabled, and a renewed input will be required to start

the gate again. Should the gate be restarted and the signal occur again prior to

reaching a limit, the gate will stop again, and this time will sound the emergency

alarm and lock out.

4 & 51 CLOSE Thisfunction works exactly like theOPENOBSTRUCTION,except that it will only

work in the closing direction.

4 & 11 SHADOW/HOLD Thisfunctionwill keep the gate initsfully open position while thesignalispresent.

Thisistypicallyusedwithaloopandloopdetectortokeepalargeswing gate open

whilevehiculartrafficispassingthrough.

24VDC+& 60 RUN/PRE-START A 24VoltDC device such as a strobe light oralarm can be wired to theseterminals.

Dependingon dip switch #2, thesedeviceswilleitherbegintwo seconds before the

operator starts, or only while the motor is running. (See page 9for details.)

OBSTRUCTION

OBSTRUCTION

GSLG-A OPERATOR INSTALLATION GUIDE

- 11 -

CURRENTSENSINGADJUSTMENTS

Because gates vary in construction and may have different force requirements in the open and close directions to move, the

OSCO control board has separate Multi-turn potentiometers for adjusting in both directions independently. The adjustment

shouldbesetlightenoughto maintain minimal force (50-75 lbs.) should an obstruction occur,buthighenough to keep the gate

movingunder normal conditions without interruption.

Priortoadjustingtheoperatorcurrentsensingfunctions, make sure the gate moves freely in both directions. A badlyaligned or

poorlymaintainedgatemaycause false triggering of the current sensor.Referto page 9when following the instructions below.

Afactory adjustment tool hasbeensupplied to make theseadjustmentseasier. This tool hasbeen taped to thecontrolbox for

yourconvenience. CLOSEDIRECTIONCURRENTSENSEADJUSTMENT

When the gate operator leaves the factory, it has been preset for a relatively light gate function and will require additional

adjustment.Begin by startingthe gate going closed.If the operatorstops and reverses, turn the close directionpotentiometer

(see page 9) one turn higher, press the STOP button, and try again. Repeat this process until the gate no longer causes false

trippingofthecurrentsensor. Note that each time the gate operator reverses, the STOP buttonmustbepressed.Next,turnthe

close direction potentiometer lower slowly while the operator is running the gate closed until the gate operator stops and

reverses again. From this point, turn the close direction potentiometer higher by 1 1/2 turns for all 115 Volt AC and 24 Volt DC

operators, and by 3/4 of a turn higher for all 230 Volt AC operators.

OPENDIRECTIONCURRENTSENSEADJUSTMENT

Repeatthesameprocesswiththeopen direction potentiometer while running the gate in the opendirection. Once thisis done,

run the gate through several complete cycles and make sure the gate does not false trip in either direction.

MAXIMUMRUNTIMERADJUSTMENT

Thisadjustablepotentiometersetsthemaximumlength of time the motor will run before shutting down. Itshould be configured

for the time it takes to run the gate fully open or closed, plus an additional 15 seconds. See page 9for details.

AUTOCLOSETIMERADJUSTMENT

Thisadjustable potentiometer sets the lengthoftimewhichelapsesbefore the gate operator automaticallyclosesthegate,from

thefully openposition,provided noopen,reversing,or obstructionsignalsarepresent. Thisfeaturecan beturnedonor offviadip

switch selection. See page 9for details. Do not use the auto close timer without an appropriate reversing device

installed!

MASTER/SLAVECONNECTION

A three-wire shielded conductor cable is required to connect master and slave operators. You must use Belden 8760 Twisted

PairShielded Cable (orequivalent)only– OSCO partnumber2500-1982,perfoot). See page9fordetailsof this connection,as

well as dip switch selection. Note: The SHIELD wire should be connected in both the master and slave operators. In addition, you

must run power to both the master and slave operators.

Multi-turn Potentiometer

Remember it is important not to set the adjustment

too high! Doing so will defeat the purpose of the cur-

rent sensing as an obstruction detecting feature.

GSLG-A OPERATOR INSTALLATION GUIDE

- 12 -

ONBOARDL.E.D.INDICATORDESCRIPTIONS

Control Board L.E.D. Indicators:

OPEN This indicator is lit when an open signal is present. This signal can come from such devices as button

stations, radio receivers, keypads and telephone entry systems.

CLOSE This indicator is lit when a closed signal is present. This signal typically comes from three-button stations.

STOP This indicator is lit when there is a break in the stop circuit. Make sure there is a stop button wired in and

workingproperly.

SINGLE This indicator is lit when a signal from a single-button station or radio receiver is present.

CLOSEOBST This indicator is lit when aclose obstruction signalispresent.Thissignal can come from edges and photo

eyes which have been wired to the close obstruction inputs.

OPENOBST This indicator is lit when an open obstruction signal is present. This signal can come from edges and

photoeyes which have been wiredtothe open obstruction inputs.

SAFETYLOOP This indicator is lit when a reversing signal is present. This signal is generated by a loop detector wired to

the safety loop terminals.

SHADOWLOOP This indicatoris lit whena shadow/hold open signalis present. Thissignal is generated bya loop detector

wiredto the shadow loop terminals.

Thisindicator is lit when the open #1 limit switch is activated on a right-handoperator, or the close #1 switch

on a left-hand. If this indicator is lit and the gate is not in its full open/closed position, the limit may need

adjusting or the limit switch may need replacing.

Thisindicator is lit when the open #2 limit switch is activated on a right-handoperator, or the close #2 switch

ona left-hand.

Thisindicator is litwhen the close#1 limit switch is activated on a right-hand operator, or the open #1 on a

left-hand. If this indicator is lit and the gate is not in its full open/closed position, the limit may need

adjusting or the limit switch may need replacing.

Thisindicator is lit when the close #2 limit switch is activated on a right-handoperator, or the open #2 switch

ona left-hand.

Motor Board L.E.D. Indicators:

NONLABELED Oneofthese two indicators will belitwhen the motor is runningthegate open, and the otherislit when the

motor is running the gate closed.

BRAKEREL. This indicator is lit when the brake is NOT applied.

LSO-1

LSO-2

LSC-1

LSC-2

LSC-1

LSC-2

LSO-1

LSO-2

LH RH

GSLG-A OPERATOR INSTALLATION GUIDE

- 13 - 12-01-5

IMPORTANTNOTESFOR

INSTALLATIONOFMASTER/SLAVEAPPLICATIONS

When setting up Master/Slave gate operators, it is best to make adjustments and run each operator individually. To do this,

simply:

a. SetDipSwitch#4toproperhand of operation (right-hand or left-hand)

b. Set Dip Switch #8 as Master (off)

Runeachoperator making current sensing adjustments asnecessary, as indicated ontheControlBoard Adjustments page of

this installation guide. When both operators have been adjusted, turn power off, then turn on Dip Switch #8 in the operator

chosenas the Slave.

Thetimer to close and radio/singlebuttonbehavior are set in theMaster operator.

Thefollowingselectionsaresetindividually:

CurrentSensing

MaximumRun Timer

One-SecondLock Release

Three-SecondPre-Start Warning

Right/Left-HandSelections

GSLG-A OPERATOR INSTALLATION GUIDE

- 14 -

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

GSLG-A OPERATOR INSTALLATION GUIDE

- 15 -

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

GSLG-A OPERATOR INSTALLATION GUIDE

- 16 -

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

GSLG-A OPERATOR INSTALLATION GUIDE

- 17 -

CONTROLandACCESSORYCONNECTIONILLUSTRATIONS

GSLG-A OPERATOR INSTALLATION GUIDE

- 18 -

LOOPLAYOUTILLUSTRATION

Referto Connection Descriptions on page10and Loop Accessory Connections onpage 17 for details.

2-03-10

GSLG-A OPERATOR INSTALLATION GUIDE

- 19 -

EDGELAYOUTILLUSTRATION#1

RefertoConnection Descriptions on page 10andContact Edge Connections on page16for details.

GSLG-A OPERATOR INSTALLATION GUIDE

- 20 -

EDGELAYOUTILLUSTRATION#2

RefertoConnection Descriptions on page 10andContact Edge Connections on page16for details.

Table of contents

Other OSCO Gate Opener manuals

Popular Gate Opener manuals by other brands

Dea

Dea 203RR Instructions and warnings

TOPP

TOPP DUEVILLE Instructions for installation and use

CAME

CAME AMICO Series installation manual

DKS

DKS 6524-081 Installation and owner's guide

tousek

tousek TPS 60 PRO m6 Mounting and installation manual

Norton

Norton 5700 LEO series Installation and instruction manual