OSCO LA36 User manual

Oct. 2005, Rev. 12

LL

LL

LAA

AA

A3636

3636

36

INSINS

INSINS

INSTT

TT

T

ALAL

ALAL

ALLL

LL

LAA

AA

ATT

TT

TIONGUIDEIONGUIDE

IONGUIDEIONGUIDE

IONGUIDE

OPERATORSPECIALTYCOMPANY,INC.OPERATORSPECIALTYCOMPANY,INC.

OPERATORSPECIALTYCOMPANY,INC.OPERATORSPECIALTYCOMPANY,INC.

OPERATORSPECIALTYCOMPANY,INC.

CASNOVIA, MI 49318 • U.S.A.

®

OSCO REQUIRES THE USE OF CONTACT EDGES OR

PHOTOELECTRIC CONTROLS ON ALL AUTOMATIC

OR REMOTELY-CONTROLLED GATE OPERATORS.

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 2 -- 2 -

- 2 -- 2 -

- 2 -

TABLEOFCONTENTSTABLEOFCONTENTS

TABLEOFCONTENTSTABLEOFCONTENTS

TABLEOFCONTENTS

PRE-INSTALLATION INFORMATION

Safety Information and Warnings ........................................................................................................................................ 3

Pre-Installation Information .................................................................................................................................................. 3

Warranty............................................................................................................................................................................... 3

INSTALLATION

Wiring Specifications ........................................................................................................................................................... 4

Post/Pillar Bracket Installation ............................................................................................................................................ 5

Gate Bracket Installation ..................................................................................................................................................... 5

Control Box Mounting .......................................................................................................................................................... 5

Gate Layout Illustration........................................................................................................................................................ 6

Limit Switch Adjustment...................................................................................................................................................... 7

CONTROL BOARD ADJUSTMENTS and ACCESSORY CONNECTIONS

Control Board Adjustments ................................................................................................................................................. 8

Terminal Connection Descriptions ....................................................................................................................................... 9

Current Sensing Adjustments ........................................................................................................................................... 10

Close Direction Current Sense Adjustment ...................................................................................................................... 10

Open Direction Current Sense Adjustment....................................................................................................................... 10

Maximum Run Timer Adjustment...................................................................................................................................... 10

Auto Close Timer Adjustment ........................................................................................................................................... 10

Battery Back-Up Charger Board Configuration ................................................................................................................. 10

Master/Slave Connection................................................................................................................................................... 10

Onboard L.E.D. Indicator Descriptions.............................................................................................................................. 11

Charger Board Sleep Mode ............................................................................................................................................... 12

Surge Protector Instructions.............................................................................................................................................. 12

Control and Accessory Connection Illustrations .......................................................................................................... 13-16

ILLUSTRATIONS

Loop Layout Illustration...................................................................................................................................................... 17

Edge Layout Illustration ..................................................................................................................................................... 18

Photo Eye Illustration ........................................................................................................................................................ 19

TROUBLESHOOTING ........................................................................................................................................................... 20

PARTS LISTS

How to Order Replacement Parts...................................................................................................................................... 20

Model LA36 Mechanical Parts Exploded View and Parts List......................................................................................... 21

Model LA36 Control Box Exploded View and Parts List .................................................................................................. 22

PREVENTATIVE MAINTENANCE ......................................................................................................................................... 23

Battery Maintenance.......................................................................................................................................................... 23

GATE OPERATOR INSTALLATION CHECKLIST ................................................................................................................ 24

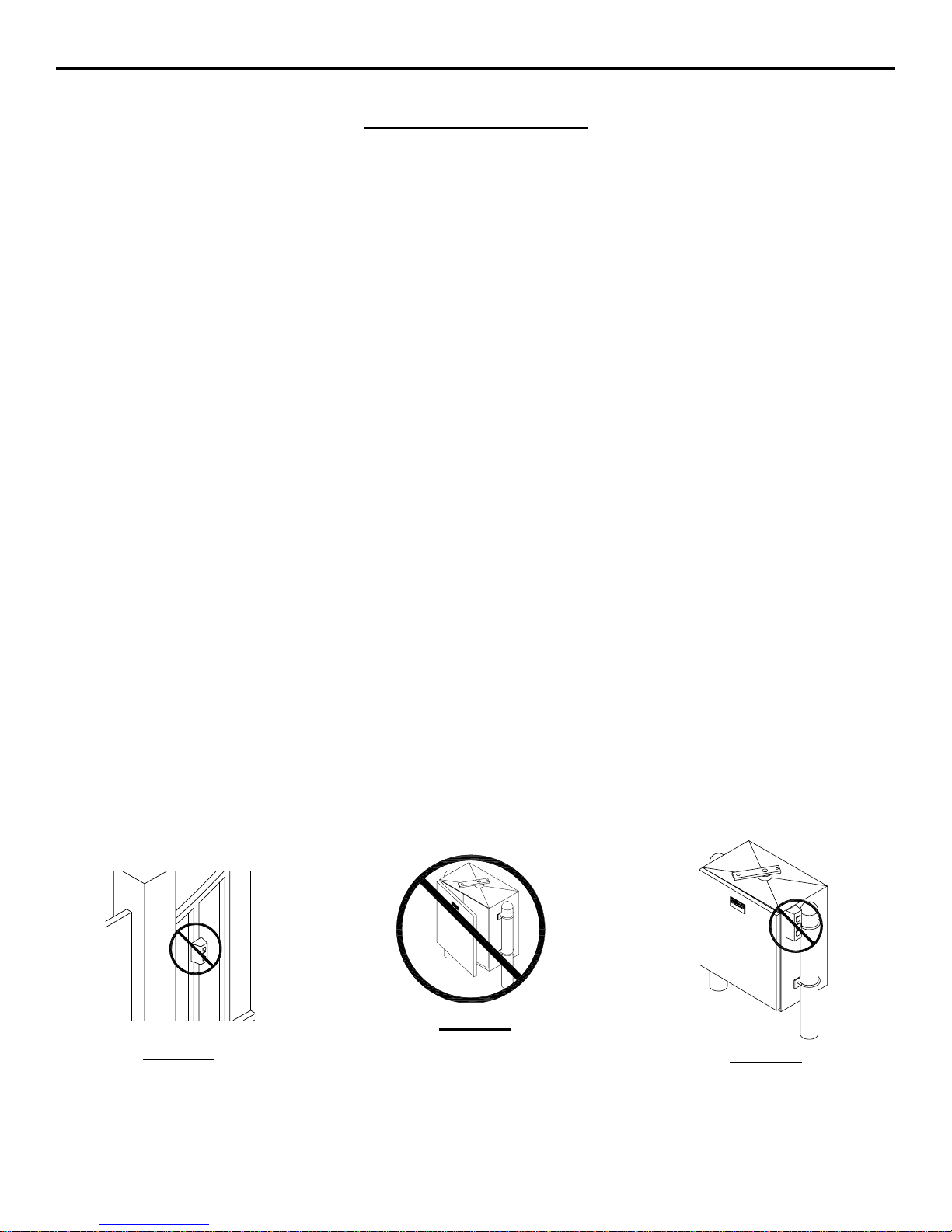

CAUTION!

DO NOT INSTALL

CONTROLSON OR

NEARTHEGATE

CAUTION!

DO NOT INSTALL

CONTROLSON

THEOPERATOR

CAUTION!

ONLYQUALIFIED SERVICE

TECHNICIANSSHOULD

WORK ON AN OSCO

SWINGGATEOPERATOR

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 3 -- 3 -

- 3 -- 3 -

- 3 -

Read the following before beginning to install OSCO swing

gateoperators:

1. Readthe orange“SafetyInstructions” brochureenclosed

with the packet of information. If you do not have one,

pleasecallOSCOat1-800-333-1717torequestone. Read

andfollow all instructions.

2. All electrical connections to the power supply must be

made by a licensed electrician and must observe all

national and local electrical codes.

3. A separate power-disconnect switch should be located

nearthe operatorso thatprimary powercan beturned off

whennecessary.

4. Install the enclosed warning signs on both sides of the

gate. Each sign must be plainly visible from the side of

the gate on which they are mounted.

5. Never reach between, through or around the fence to

operatethe gate.

6. You must install all required safety equipment.

GATEOPERATORCLASSIFICATIONSGATEOPERATORCLASSIFICATIONS

GATEOPERATORCLASSIFICATIONSGATEOPERATORCLASSIFICATIONS

GATEOPERATORCLASSIFICATIONS

All gate operators can be divided into one of four different

classifications,depending on theirdesign and usage.

Class I Residential Vehicular Gate Operator

Avehiculargate operatorintended foruse in ahome ofone to

foursingle familydwellings,or garageor parkingarea associ-

atedwith these dwellings.

Class II Commercial / General Access Vehicular Gate

Operator

A vehicular gate operator intended for use in a commercial

location or building such as a multifamily housing unit of five

ormore singlefamily units, hotel,retail storeor other building

servicingthe generalpublic.

Class III Industrial / Limited Access Vehicular Gate

Operator

A vehicular gate operator intended for use in an industrial

location or building such as a factory or loading dock area or

otherlocation not intendedto service thegeneral public.

Class IV RestrictedAccess Vehicular Gate Operator

Avehiculargate operatorintendedfor useina guardedindus-

trial location or building such as an airport security area or

other restricted access locations not servicing the general

public,inwhich unauthorizedaccessis preventedviasupervi-

sion by security personnel.

PRE-INSTALLATIONPRE-INSTALLATION

PRE-INSTALLATIONPRE-INSTALLATION

PRE-INSTALLATION

INFORMATIONINFORMATION

INFORMATIONINFORMATION

INFORMATION

Before unpacking, inspect the carton for exterior damage. If

youfinddamage,advisethedeliverycarrierofapotentialclaim.

Inspect your package carefully. You can check your

accessory box parts with the enclosed packing slip for your

convenience.Claimsfor shortageswill behonoredfor only30

days from the date of shipment.

Before installing the operator, read this manual completely

toensure all requirementsfor properinstallation are present.

Verify that the voltage to be used matches the voltage of the

operator.

SAFETYINFORMATIONSAFETYINFORMATION

SAFETYINFORMATIONSAFETYINFORMATION

SAFETYINFORMATION

AND WARNINGSAND WARNINGS

AND WARNINGSAND WARNINGS

AND WARNINGS

IMPORTANT!!

Beforeinstallingthe gateoperator,make surethegate’sswing

is free and level throughout the entire swing path. If the gate

does not seem to operate properly, it may affect the operator

performance or greatly shorten the life of the unit. The gate

should be designed so that airflow is ample to prevent wind

resistanceand drag.

The following contact or non-contact obstruction

detection devices have been approved for use

with OSCO slide gate operators as part of a UL325

compliant installation:

ContactEdges:

MillerModels*: MG0-20,MGR-20, MGS-20,and ME-120

Photoeyes:

2520-441 MMTCModel IR-55 photoeye,165’ with

mountinghardware

2520-031 MMTC Model E3K photoeye, 28’ with

mountinghardware

*for OSCO part numbers, contact a sales representative for details

10-05-12

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 4 -- 4 -

- 4 -- 4 -

- 4 -

USE COPPER WIRE ONLY!

MODEL LA36MODEL LA36

MODEL LA36MODEL LA36

MODEL LA36

gniriWrewoP

stloV

PH&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

V5118823

4225

4461

2162

41

21

MODEL LA36MODEL LA36

MODEL LA36MODEL LA36

MODEL LA36

ACCESSORY WIRINGACCESSORY WIRING

ACCESSORY WIRINGACCESSORY WIRING

ACCESSORY WIRING

All DC Models

24VDC

0-2000

14

Volts

Maximum

Distance (ft.)

Wire

Gauge

1. Select from the chart at the bottom of this page corre-

spondingto the model,voltage and horsepower rating of

youroperator.

2. Thedistanceshown onthe chartis measuredinfeet from

theoperatortothe powersource.DO NOTEXCEED THE

MAXIMUM DISTANCE. These calculations have been

based on standard 115V with a 10% drop allowable. If

your supply is under the standard rating, the runs listed

maybelonger thanwhat yourapplication willhandle,and

you should not run wire too near the upper end of the

chartfor the gauge ofwire you areusing.

3. When large-gauge wire is used, a separate junction box

(notsupplied)may beneededforthe operatorpowercon-

nection.

WIRINGSPECIFICATIONSWIRINGSPECIFICATIONS

WIRINGSPECIFICATIONSWIRINGSPECIFICATIONS

WIRINGSPECIFICATIONS

4. Allcontroldevices arenow24VDC,which canberuncon-

siderabledistances.

5. Wireruncalculations arebased onthe NationalElectrical

Code, Article 430 and have been carefully determined

basedon motorinrush, brakesolenoids,and operatorre-

quirements.

6. Connectpowerinaccordancewithlocalcodes.The green

ground wire must be properly connected.

7. Wire insulation must be suitable to the application.

8. Controlwiringmustberuninaseparateconduitfrompower

wiring.Runningthemtogethermaycauseinterferenceand

faulty signals in some accessories.

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 5 -- 5 -

- 5 -- 5 -

- 5 -

CONTROLBOX MOUNTINGCONTROLBOX MOUNTING

CONTROLBOX MOUNTINGCONTROLBOX MOUNTING

CONTROLBOX MOUNTING

For dual-leaf applications, both linear drive motors will connect to a single control box. Locate the control box in the vicinity of

eitherlinear actuator motor.Mount the boxfirmly to anon-movable object.Knockouts areprovided for conduits.Do notmount

the control box where a lawn sprinkler may spray water on it.

NOTE: Wheninstalling thecable connecting theoperator to the control box,be sure toleave someslack to allowfor theswing

ofthe gate. Water tight connectors arehighly recommended.

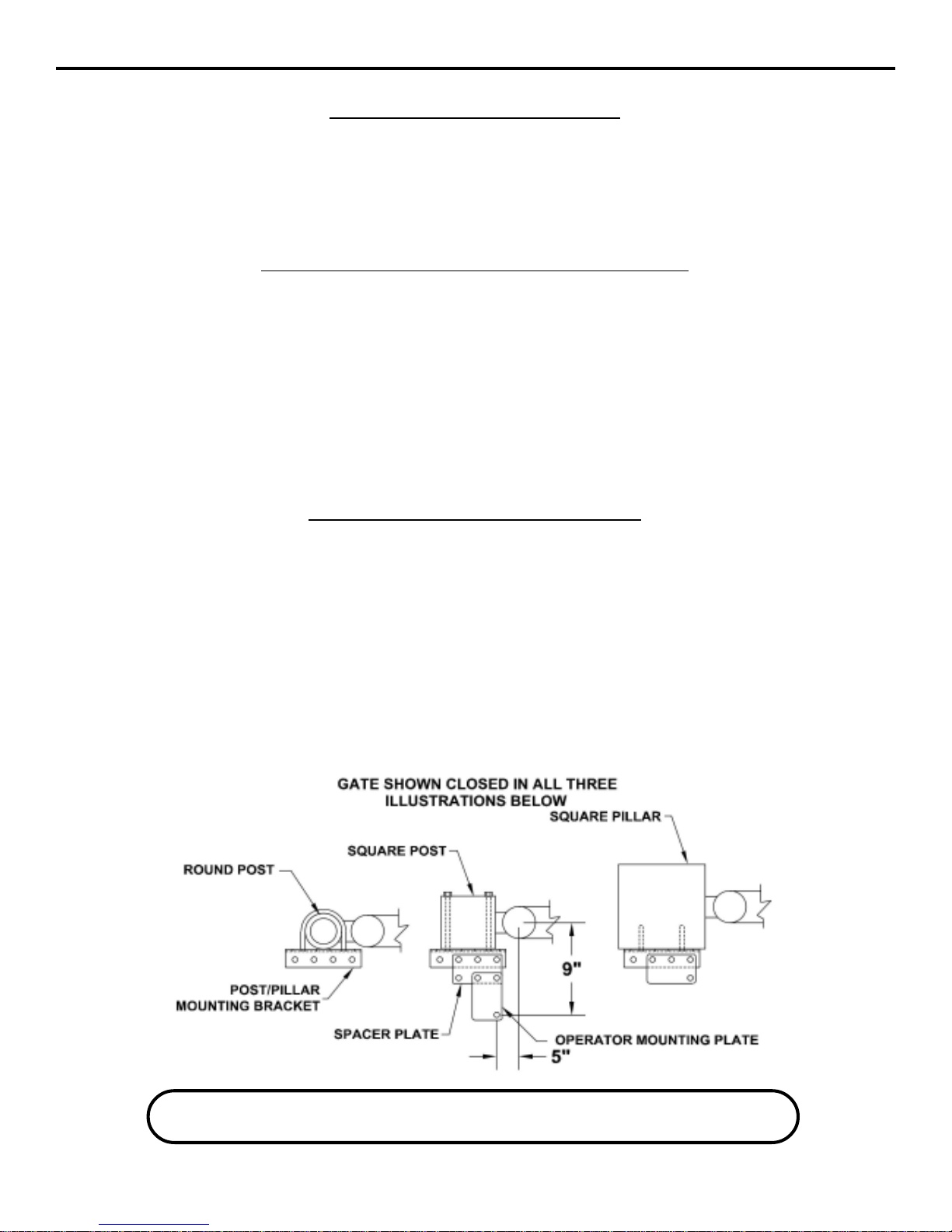

POST/PILLAR BRACKET INSTALLATIONPOST/PILLAR BRACKET INSTALLATION

POST/PILLAR BRACKET INSTALLATIONPOST/PILLAR BRACKET INSTALLATION

POST/PILLAR BRACKET INSTALLATION

Severalbrackets havebeensupplied forpost orpillar mounting.The postpillar bracket,operatormounting bracket,and spacer

plate can be combined in various configurations to fit most applications. It is very important to achieve the required mounting

locationforproper operationand toavoid premature failure.

1. Locatethe post pillarbracket verticallyapproximately halfway upfrom the groundrelative to theoverall gateheight.

2. If mounting to a round post of 4” diameter or less, use two U-bolts to attach the post/pillar bracket.

3. Ifmounting toa square post,use eitherthrough boltsor, if applicable,weld thebracket to thepost directly.Avoiddrilling into

mortarjointswherever possible.

4. When mounting to a pillar, anchor the bracket using 1/2” lag bolts and lag bolt anchors. Drill 3/4” diameter holes to a depth

of 4” using a rotary hammer percussion drill. Insert lag bolt anchors for 1/2” diameter lag bolts. Lubricate bolts before

installationand tighten inplace when done.

GATEBRACKETINSTALLATIONGATEBRACKETINSTALLATION

GATEBRACKETINSTALLATIONGATEBRACKETINSTALLATION

GATEBRACKETINSTALLATION

Referto the illustrationon thefollowing page.

1. Openthe gate toapproximately 90 to 95degrees (full open position).

2. Carefullymount the operator to the post/pillar bracket assemblyand hold the frontend of the operatorlevel and in its fully

open position.If necessary, youcan temporarilyapply powerto theoperator toopen itfully. DO NOTALLOW THE DRIVE

TUBE TO SPIN!

3. Line up the gate bracket with the linear actuator and mark the position. Clamp the bracket in place. Once its final position

is set, permanently attach the bracket.

4. Runthe operator to the fully-closed position,adjusting the closelimit as neededto achieve fulltravel. Make anymounting

changesneeded to achievefull travel withoutthe operator bindingagainst the post,gate, etc.

Thefactory suggested mountingwill use approximately 14”of stroke. Themaximum available strokefor the LA36 is18”.

ASEPARATEPEDESTRIANGATEISREQUIREDFOR ALLPEDESTRIANTRAFFIC.THISGATE

MUSTBEAMINIMUMDISTANCEOF7FEETFROMTHE VEHICULARGATEANDGATE OPERATOR

10-05-12

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 6 -- 6 -

- 6 -- 6 -

- 6 -

GATELAYOUTILLUSTRATIONGATELAYOUTILLUSTRATION

GATELAYOUTILLUSTRATIONGATELAYOUTILLUSTRATION

GATELAYOUTILLUSTRATION

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 7 -- 7 -

- 7 -- 7 -

- 7 -

LIMIT SWITCH ADJUSTMENTLIMIT SWITCH ADJUSTMENT

LIMIT SWITCH ADJUSTMENTLIMIT SWITCH ADJUSTMENT

LIMIT SWITCH ADJUSTMENT

The limit for open is adjusted by screwing the

innertubeinorout.The tubecanonlybescrewed

inabout 1/2”before bottoming out.

The limit for close isaccessedby removing the

gasketedboltinthecoupleroftherearcover.Using

astandard,1/4”-wide screwdriver,theadjustment

screw can be turned one click at a time. Each

clickadjuststheclosingpositionbyapproximately

4” for a 10-foot-wide gate. Each clockwise click

will allow the gate to swing further closed.

Fine tuning can be accomplished by turning the

tube 1/2 turns, keeping in mind that it will also

affectthe full-openposition.

WARNING!

YOU MUST TURN OFF THE POWER SWITCH

LOCATED IN THE LA36 CONTROL BOX

BEFORE ADJUSTING LIMITS OR

SERVICING THE OPERATOR.

12-04-11

DO NOT ALLOW THE DRIVE TUBE TO SPIN WHEN RUNNING!

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 8 -- 8 -

- 8 -- 8 -

- 8 -

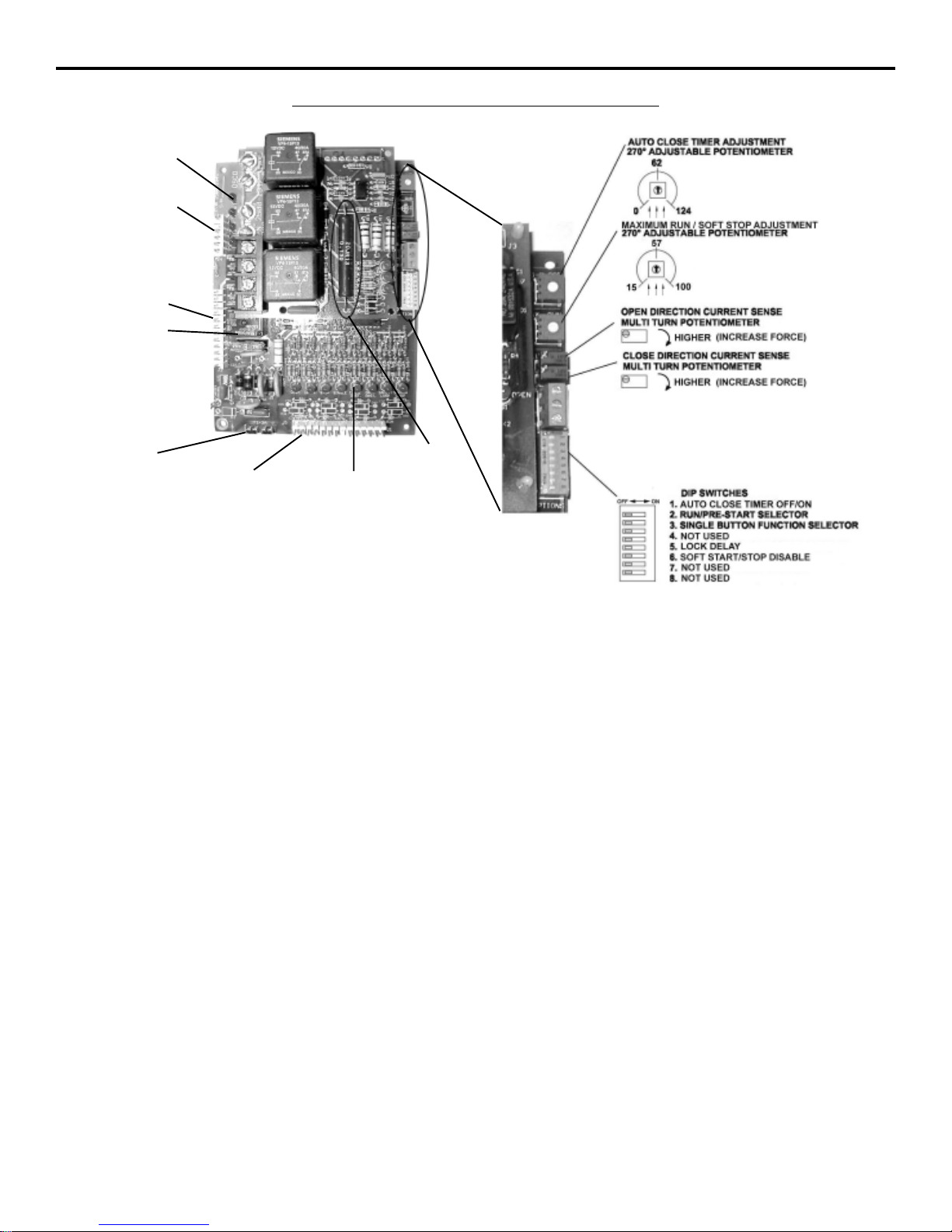

Auto Close Timer Adjustment: This 270-degree adjustable potentiometer will signal the operator to close automatically,

providednoopen, reversingorobstruction signalsare presentfromthe fully-openposition.This timerisadjustable from0 to 124

seconds. This feature is turned on or off using dip switch #1.

Maximum Run Timer Adjustment: This 270-degree adjustable potentiometer sets the amount of full speed run time for the

operator, aswell asthe maximumrun time.Thereshould be approximately threeseconds ofslow speedtravel beforereaching

the end of travel. Maximum run is set automatically as 10 seconds longer than the length of time at full speed.

Open Direction Current Sense Adjustment: This multi-turn potentiometer is used to calibrate the built-in current sensing

featurefor detection of obstructions whilerunning in theopen direction.

Close Direction Current Sense Adjustment: This multi-turn potentiometer is used to calibrate the built in current sensing

featurefor detection ofobstructions while runningin the closeddirection.

Dip Switches:

#1 This switch turns the auto close timer off/on.

#2 This switch is used in conjunction with alarms and flashing lights that may be added to the operator. When the switch is

inthe ON position, thesedevices will startapproximately two secondsprior to theoperator starting. Inthe OFF position,

thedevices will onlywork while the operatoris running.

#3 This switch is used in conjunction with single-button controls and radio receivers. In the ON position, successive inputs

will cause signals in the order of OPEN-STOP-CLOSE-STOP. In the OFF position, inputs will cause an OPEN signal

unless the gate is fully open, in which case it will signal CLOSE.

#4 Not used at this time.

#5 When turned ON, this switch will allow a one-second delay for solenoid locks to unlock before the motor starts.

#6 WhenturnedON, thisswitch disablesthe soft start/stopfeature. Ifthe switchis inthe OFFpositionand thesoft start/stop

isn’tnoticeable, remove one of the twoR2 resistors.

#7 Not used at this time.

#8 Not used at this time. Set to OFF.

CONTROLBOARD ADJUSTMENTSCONTROLBOARD ADJUSTMENTS

CONTROLBOARD ADJUSTMENTSCONTROLBOARD ADJUSTMENTS

CONTROLBOARD ADJUSTMENTS

12-04-11

NOTE:DONOTFORCE270-DEGREEPOTENTIOMETERS

BEYONDTHEIRNORMALRANGEOFMOTION

ORDAMAGEMAYRESULT!

Control Board

with DC

Motor Board

DIAGNOSTIC

L.E.D.s

TERMINAL STRIP #2

CONNECTOR

TERMINAL STRIP #1

CONNECTOR

LIMIT SWITCH

CONNECTOR

LIMIT SWITCH

L.E.D.s

3A Fuse

2A Fuse SOFT

START/STOP

RESISTOR

R2

(1 of 2 shown)

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 9 -- 9 -

- 9 -- 9 -

- 9 -

You must follow all required safety precautions and instructions at all times. Review the safety brochure

included with the operator. If any pages are missing or unreadable, contact OSCO at 1-800-333-1717 to request

additional copies.

Never connect a button station within reach of the gate or on the side of the gate operator or operator

control box.

Do not adjust the circuit board current sensing feature too high. It should be adjusted high enough to keep the

gate from falsely triggering the sensing, but no higher than necessary for the gate to operate. Do not defeat the

purpose of this function!

TERMINALCONNECTIONDESCRIPTIONSTERMINALCONNECTIONDESCRIPTIONS

TERMINALCONNECTIONDESCRIPTIONSTERMINALCONNECTIONDESCRIPTIONS

TERMINALCONNECTIONDESCRIPTIONS

TERMINALS FUNCTION DESCRIPTIONOF FUNCTION

24VDC+ 24VDC Providesfused 24VoltDCpower for accessories.

24VDC- COMM.

1 & 4 OPEN Opensthe operator.Several accessories suchas button stations,keypads, trans-

mitters and card readers can be wired to open.

3 & 4 CLOSE Closes the operator. Use caution when wiring accessories to these terminals.

The gate must be clearly visible from the location of any accessories wired

to close.

4 & 5 SINGLE-BUTTON Performs the single-button function which will alternate between open and close

or open, stop and close - depending on dip switch #3. (See page 8for details.)

2 & 4 STOP Stops the operator. If no stop button is used, a jumper is required across 2&4.

4 & 6 REVERSE Thisfunction will cause a reversal when the gate istraveling closed and willtravel

back to the fully open position. Loop detectors are often wired for reverse.

4 & 50 OPEN This function works only while the operator is opening. Any signal to this function

will cause the gate to stop, reverse a short distance, and then stop again. At this

time the auto close timer is disabled, and a renewed input will be required to start

the gate again. Should the gate be restarted and the signal occur again prior to

reaching a limit, the gate will stop again, and this time will sound the emergency

alarm and lock out.

4 & 51 CLOSE This functionworks exactlylike the OPENOBSTRUCTION, except thatit will only

work in the closing direction.

4 & 11 SHADOW/HOLD Thisfunction will keepthe gate inits fullyopen position whilethe signal ispresent.

This is typically used with a loop and loop detector to keep a large swing gate

open while vehicular traffic is passing through.

24VDC+& 60 RUN/PRE-START A24VoltDC devicesuch asa strobelight oralarm canbe wired to these terminals.

Depending on dip switch #2, these devices will either begin three seconds before

the operator starts, or only while the motor is running. (See page 8 for details.)

OBSTRUCTION

OBSTRUCTION

12-04-11

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 10 -- 10 -

- 10 -- 10 -

- 10 -

CURRENTSENSING ADJUSTMENTSCURRENTSENSING ADJUSTMENTS

CURRENTSENSING ADJUSTMENTSCURRENTSENSING ADJUSTMENTS

CURRENTSENSING ADJUSTMENTS

Because gates vary in construction and may have different force requirements in the open and close directions to move, the

OSCO control board has separate Multi-turn potentiometers for adjusting in both directions independently. The adjustment

should be set light enough to maintain minimal force (40 lbs.) should an obstruction occur, but high enough to keep the gate

movingunder normalconditionswithout interruption.

Priorto adjustingthe operatorcurrent sensingfunctions, makesure the gatemoves freelyin bothdirections. Abadly alignedor

poorlymaintained gatemay causefalse triggeringof the currentsensor. Referto page8when following the instructionsbelow.

Afactory adjustmenttool hasbeen supplied tomake theseadjustments easier.Thistool canbe foundin theinformationpacket.

CLOSEDIRECTION CURRENTSENSEADJUSTMENTCLOSEDIRECTION CURRENTSENSEADJUSTMENT

CLOSEDIRECTION CURRENTSENSEADJUSTMENTCLOSEDIRECTION CURRENTSENSEADJUSTMENT

CLOSEDIRECTION CURRENTSENSEADJUSTMENT

When the gate operator leaves the factory, it has been preset for a relatively light gate function and will require additional

adjustment.Begin by starting the gategoing closed. If the operatorstops and reverses, turn the close direction potentiometer

(see page 8) one turn higher, press the STOP button, and try again. Repeat this process until the gate no longer causes false

trippingof thecurrent sensor.Note that eachtime thegate operatorreverses, theSTOP buttonmustbe pressed.Next, turn the

close direction potentiometer lower slowly while the operator is running the gate closed until the gate operator stops and

reversesagain. From thispoint, turn the close direction potentiometer higherby 1 1/2turns. Additional adjustmentby 1/2-turn

increments may be necessary.

OPENDIRECTION CURRENTSENSE ADJUSTMENTOPENDIRECTION CURRENTSENSE ADJUSTMENT

OPENDIRECTION CURRENTSENSE ADJUSTMENTOPENDIRECTION CURRENTSENSE ADJUSTMENT

OPENDIRECTION CURRENTSENSE ADJUSTMENT

Repeatthe sameprocess withthe opendirection potentiometer whilerunning thegate inthe opendirection. Once this is done,

run the gate through several complete cycles and make sure the gate does not false trip in either direction.

MAXIMUM RUN TIMER ADJUSTMENTMAXIMUM RUN TIMER ADJUSTMENT

MAXIMUM RUN TIMER ADJUSTMENTMAXIMUM RUN TIMER ADJUSTMENT

MAXIMUM RUN TIMER ADJUSTMENT

This adjustable potentiometer sets the full speed run time for the

operator, as well as the maximum run time. There should be

approximately three seconds of slow speed travel before reach-

ing the end of travel. Maximum run is set automatically as ten

seconds longer than the length of time at full speed. See page 8

for details.

AUTO CLOSE TIMER ADJUSTMENTAUTO CLOSE TIMER ADJUSTMENT

AUTO CLOSE TIMER ADJUSTMENTAUTO CLOSE TIMER ADJUSTMENT

AUTO CLOSE TIMER ADJUSTMENT

This adjustable potentiometer sets the length of time which

elapses before the gate operator automatically closes the gate,

from the fully open position, provided no open, reversing, or ob-

struction signals are present. This feature can be turned on or off

via dip switch selection. See page 8for details. Do not use the

auto close timer without an appropriate reversing device in-

stalled!

MASTER/SLAVE CONNECTIONMASTER/SLAVE CONNECTION

MASTER/SLAVE CONNECTIONMASTER/SLAVE CONNECTION

MASTER/SLAVE CONNECTION

Wire the black and red wires of both operators to M1 and M2 on

the motor board.

BATTERYBACK-UPBATTERYBACK-UP

BATTERYBACK-UPBATTERYBACK-UP

BATTERYBACK-UP

FOR DC MODELS ONLYFOR DC MODELS ONLY

FOR DC MODELS ONLYFOR DC MODELS ONLY

FOR DC MODELS ONLY

CHARGERBOARDCONFIGURATIONCHARGERBOARDCONFIGURATION

CHARGERBOARDCONFIGURATIONCHARGERBOARDCONFIGURATION

CHARGERBOARDCONFIGURATION

ForModelLA36,thevoltage monitor selector switch must be left in

the RUN position to function properly. If AC power is lost, it will

allow the operator to continue to function until the batteries have

droppedto17volts.Whenthebatteries have reached 17 volts, the

operatorwillopenand shut down until the batteriesarerecharged

to24voltsfromeitherreturnofpower,solarpanels,or by installing

fresh,fullychargedbatteries.(You mustturnoff thepowerswitch

beforechangingbatteries if you choose toswapthem out!)

VOLTAGE MONITORSHOWN

ABOVEINTHERUNPOSITION

Multi-turn Potentiometer

Remember it is important not to set the adjustment

too high! Doing so will defeat the purpose of the cur-

rent sensing as an obstruction detecting feature.

12-04-11

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 11 -- 11 -

- 11 -- 11 -

- 11 -

ONBOARDL.E.D.INDICATORDESCRIPTIONSONBOARDL.E.D.INDICATORDESCRIPTIONS

ONBOARDL.E.D.INDICATORDESCRIPTIONSONBOARDL.E.D.INDICATORDESCRIPTIONS

ONBOARDL.E.D.INDICATORDESCRIPTIONS

CONTROLBOARD L.E.D. INDICATORS:

OPEN This indicator is lit when an open signal is present. This signal can come from such devices as button

stations, radio receivers, keypads and telephone entry systems.

CLOSE This indicator is lit when a closed signal is present. This signal typically comes from three-button stations.

STOP This indicator is lit when there is a break in the stop circuit. Make sure there is a stop button wired in and

workingproperly.

SINGLE This indicator is lit when a signal from a single-button station or radio receiver is present.

CLOSEOBST Thisindicator islit whenaclose obstruction signal ispresent. Thissignal cancomefrom edgesand photo

eyes which have been wired to the close obstruction inputs.

OPENOBST This indicator is lit when an open obstruction signal is present. This signal can come from edges and

photoeyes which havebeen wired tothe open obstructioninputs.

SAFETYLOOP This indicator is lit when a reversing signal is present. This signal is generated by a loop detector wired to

the safety loop terminals.

SHADOWLOOP This indicator islit when a shadow/hold open signal is present. Thissignal is generated by aloop detector

wiredto the shadowloop terminals.

These indicators are not used and will be lit at all times.

These indicators are not used and will be lit at all times.

MOTORBOARDL.E.D. INDICATORS:

NONLABELED One of thesetwo indicators willbe lit whenthe motor isrunning the gateopen, and theother is litwhen the

motor is running the gate closed.

BRAKEREL. This indicator is lit when the operator is running at full speed.

DCOPERATORS ONLY:

DCPOWER Indicates theoperator has power to operate. This indicator flashes when in sleep mode.

BATTERY

CHARGING Indicatesbatteries arebeing charged.

OPENGATE Operator is in open then lockout stage.

POWER

LOCKOUT Flashes when controls/motor are in lockout mode.

LSC-1

LSC-2

LSO-1

LSO-2

12-04-11

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 12 -- 12 -

- 12 -- 12 -

- 12 -

CHARGERBOARDSLEEP MODECHARGERBOARDSLEEP MODE

CHARGERBOARDSLEEP MODECHARGERBOARDSLEEP MODE

CHARGERBOARDSLEEP MODE

When primary AC power is not available, the operator will continue to

operate in battery only mode if the charger board is set in its RUN mode

(see Battery Backup Charger Configuration). Accessories wired into

the operator will continue to draw power, even when the operator is not

openingor closing the gate. Thiscan dramatically reduce the amountof

standbytime availablefrom the batteries.

To extend the available standby time, the charger board has a “sleep”

mode feature which will turn off power to all controls except for any that

arewiredaccordingtotheschematicsbelow.Byremovingtheblackjumper

cap JP1 located in the upper right hand corner of the charger board this

feature can be enabled. In the absence of incoming power sufficient to

change the batteries and operate the controls, the control power will be

shutoffafter15 minutesof inactivity.This will removepower toall acces-

sories except those wired as shown below. Those wired as shown will

continueto havepower atall timesand will upon activation generatefirst

a“wake” signal thatwill powerall controlsbackup, andthen createeither

anopen signal orsingle buttonsignal, dependingonhow thewire jumper

shownbelow is connected.

OPEN

TERMINAL WAKE

TERMINAL

JP1

JUMPERCAP

CHARGERBOARD

SURGEPROTECTORINSTRUCTIONSSURGEPROTECTORINSTRUCTIONS

SURGEPROTECTORINSTRUCTIONSSURGEPROTECTORINSTRUCTIONS

SURGEPROTECTORINSTRUCTIONS

The optional surge protector should be connected

to any inputs that have an accessory connected to

it. This includes the 3-button station, so it must be

connected to 1, 2A and 3 in all cases. The green

wire connected to ground, which is electrically the

same as terminal 4. The red wires connect to

terminals 2A and 24VDC+. This will cause the

2 amp fuse to blow if this section of the module

becomes shorted. With any of the other inputs

connectedto the surge protector, if theirprotection

linebecomes shorteddueto asurge overthe rating

of the module, the corresponding LED on the main

board will remain lit, causing a constant signal to

the controller. If this is found, please replace the

entiresurge protector with a newunit.

Do not simply unhook the shorted wire, as this

removesthe protection from the circuit that was

saved by the protector in the first place!

12-04-11

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 13 -- 13 -

- 13 -- 13 -

- 13 -

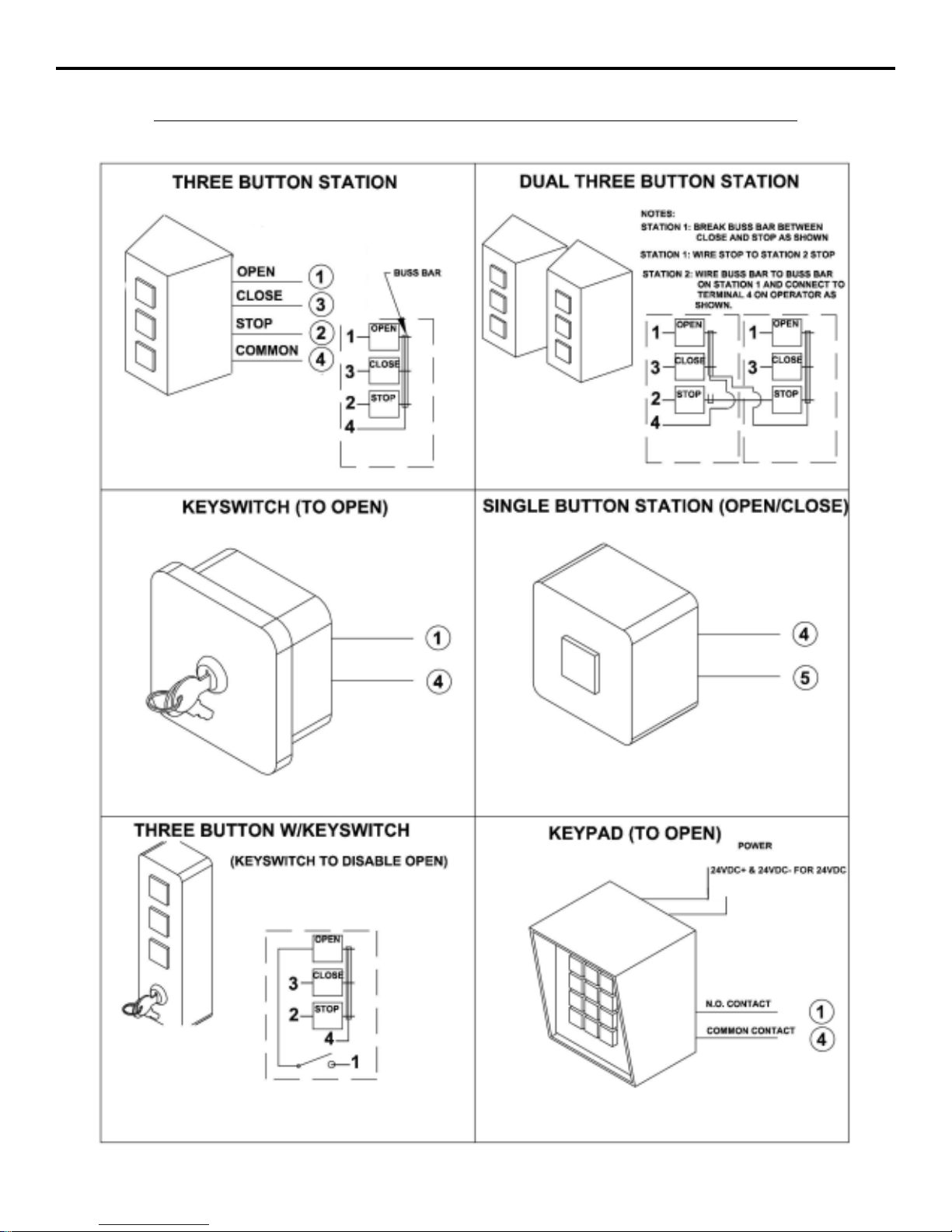

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

10-02-3

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 14 -- 14 -

- 14 -- 14 -

- 14 -

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

5-04-9

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 15 -- 15 -

- 15 -- 15 -

- 15 -

OSCO CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSOSCO CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

OSCO CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSOSCO CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

OSCO CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 16 -- 16 -

- 16 -- 16 -

- 16 -

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONSCONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS

12-04-11

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 17 -- 17 -

- 17 -- 17 -

- 17 -

LOOPLAYOUTILLUSTRATIONLOOPLAYOUTILLUSTRATION

LOOPLAYOUTILLUSTRATIONLOOPLAYOUTILLUSTRATION

LOOPLAYOUTILLUSTRATION

Referto Connection Descriptionson page 9and Loop AccessoryConnections on page16 for additionaldetails.

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 18 -- 18 -

- 18 -- 18 -

- 18 -

EDGE LAYOUT ILLUSTRATIONEDGE LAYOUT ILLUSTRATION

EDGE LAYOUT ILLUSTRATIONEDGE LAYOUT ILLUSTRATION

EDGE LAYOUT ILLUSTRATION

Referto Connection Descriptionson page 9 and ContactEdge Connections onpage 15 foradditional details.

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 19 -- 19 -

- 19 -- 19 -

- 19 -

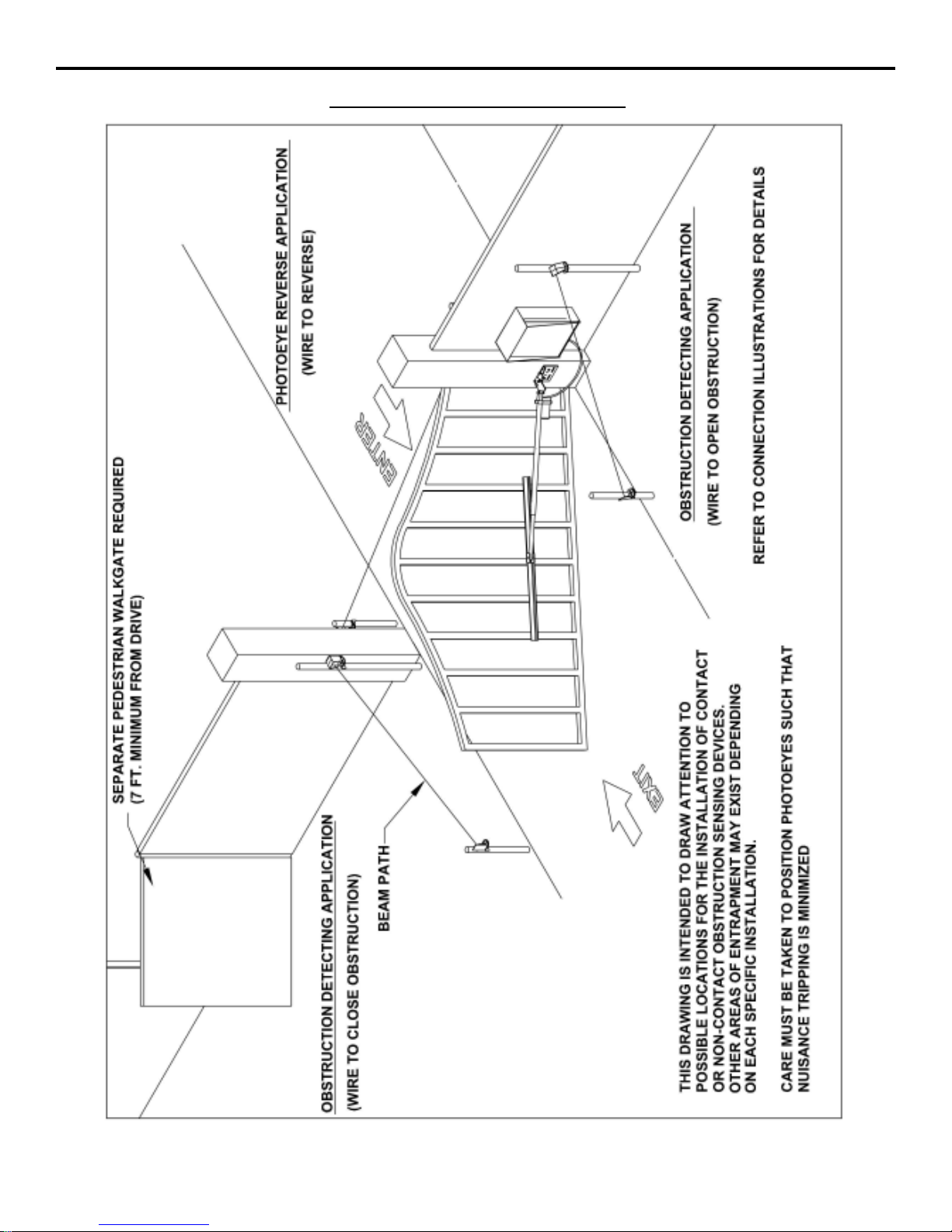

PHOTO EYE ILLUSTRATIONPHOTO EYE ILLUSTRATION

PHOTO EYE ILLUSTRATIONPHOTO EYE ILLUSTRATION

PHOTO EYE ILLUSTRATION

Referto Connection Descriptionson page 9and Photoeye AccessoryConnections on page15 for additional details.

2-03-4

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDELA36 OPERATOR INSTALLATION GUIDE

LA36 OPERATOR INSTALLATION GUIDE

- 20 -- 20 -

- 20 -- 20 -

- 20 -

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

Operatorfails to start:

A. Makesure youhavepower atthe master distributionpanel

andthat the powerhas not beenturned off.

B. The3-amp fuseonthe controlboard or chargerboard may

haveblown.Replace thefuse(refer tocontrolbox partslist

onpage 22.

Motor operates, but gate does not move:

A. Makesure all mountinghardware is stillattached andthat

all fasteners are tight.

B. Check that the actuator cylinder is moving. If it isn’t, the

gearsin thedrive mayhave stripped.

Motor sounds like it is working harder than normal:

A. Make sure the gate is moving freely and without binding

throughoutits entiretravel.

Gate stopping part way open or closed

(but no visible obstruction):

A. The control board may have received a false obstruction

input triggered by current sensing set too low. Make sure

the gate moves freely through its entire travel before ad-

justing the current sensing.

B. The maximum run timer may have counted down and

expired. This can be caused by having the timer set too

low. Whenthe timer expires, thegate stopsand an alarm

willsound.

C. An obstruction signal from an accessory wired to the ob-

structioninput may havetriggered falsely.Check thecon-

trol board for lit L.E.D. indicators for any of the following

inputs: safety, shadow, open obstruction, close obstruc-

tion, stop, etc. If any are lit when the operator should be

running, remove all devices hooked to that function and

hookthem uponeat atime andtry torunthe operatoruntil

theproblemdevice isfound.Refer to page11 for detailson

thecontrol board indicators.

Gatestaying open withautomatic system:

A. Ifthere arevehicledetectors inyourmachinewhich areset

upfor reverse,one ofyour loops orloop detectorsmay be

sending a false signal. Disconnect the wire harness and

tryrunning theoperator.

B. An opening or reversing device may be stuck or malfunc-

tioning. Try disconnecting these devices and hook them

backup oneata timeand tryrunning theoperator untilthe

malfunctioningdeviceis found.

HOW TO ORDER REPLACEMENT PARTS

Use the part numbers listed on the following pages. Contact your local OSCO dealer or distributor to order parts.

1. Supplythe modelnumber and serialnumber ofyour operator.

2. Specifythe quantity ofpieces needed andorder by part numberand name ofpart.

3. State whether to ship by freight, truck, parcel post, UPS or air express.

4. Statewhether transportation chargesare to beprepaid or collect.

5. Specify name and address of person or company to whom parts are to be shipped.

6. Specify name and address of person or company to whom invoice is to be sent.

WARNING!

YOU MUST TURN OFF THE POWER SWITCH

LOCATED IN THE LA36 CONTROL BOX BEFORE

SERVICING THE GATE OR GATE OPERATOR!

KEEP CLEAR OF THE GATE DURING OPERATION!

12-04-11

Table of contents

Other OSCO Gate Opener manuals

Popular Gate Opener manuals by other brands

Novoferm tormatic

Novoferm tormatic Novomatic 200 Installation, operating and maintenance instructions

CAME

CAME U 8700 installation guide

BFT

BFT PHOBOS N BT Installer's reference guide

Nice

Nice MC824L quick guide

RIB

RIB PRINCE 24V Important Safety Instructions For The Installation

Centurion

Centurion Auto-Mate installation manual