• The fan must be installed according to the air direc-

tion label on the fan.

• The fan must be connected to duct or equipped with

a safety grille.

• The fan should be installed in a safe way and make

sure that no foreign objects are left behind.

• The fan should be installed in a way that makes ser-

vice and maintenance easy.

• The fan should be installed in a way that vibrations

can not be transfused to duct or building. To provi-

de this, use for example a duct clamp.

• To regulate the speed a transformer or thyristor can

be connected.

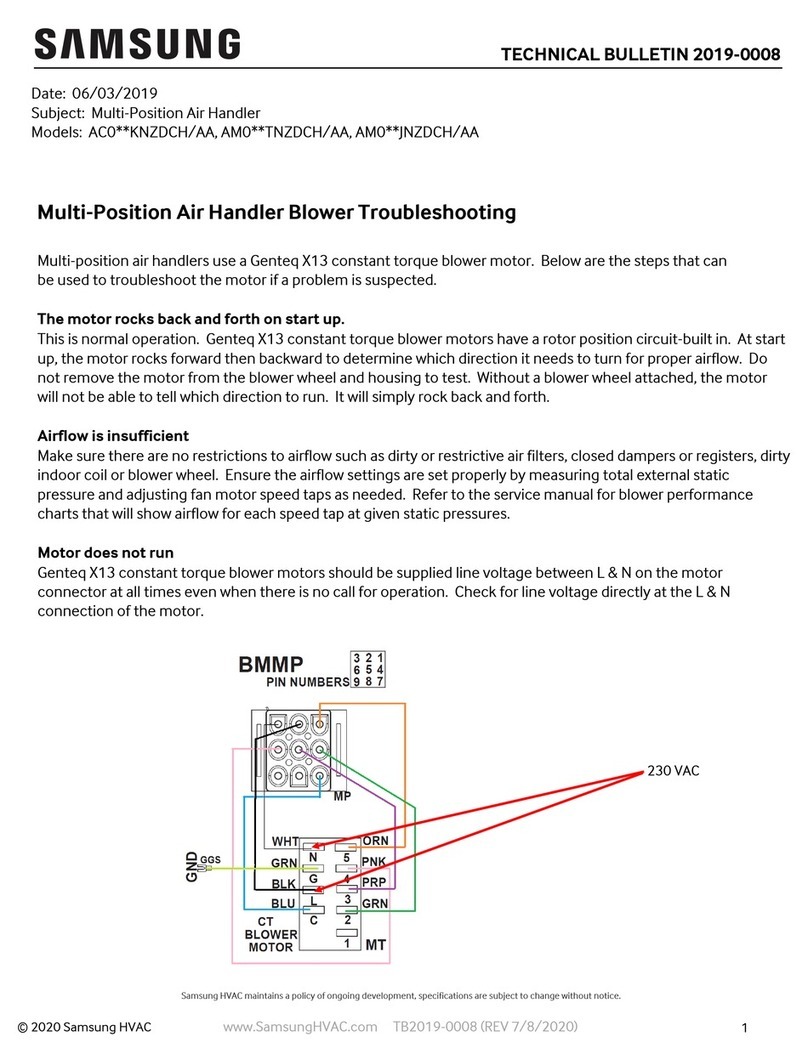

• A wiring diagram is applied on the inside of the junc-

tion box or separately enclosed.

• The fan must be installed and connected electrical-

ly in the correct way grounded.

• Electrical installations must be made by an authori-

zed electrician.

• Electrical installations must be connected to a local-

ly situated tension free switcher or by a lockable

head switcher.

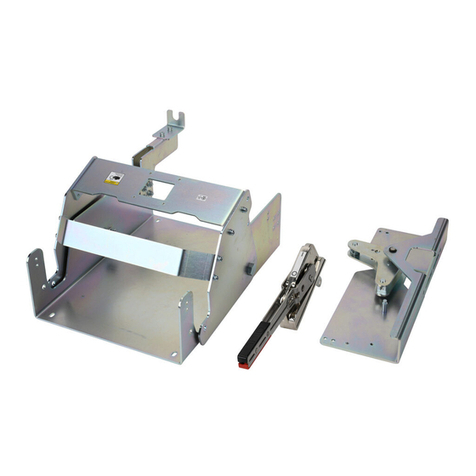

• The strain relief is in the junction box and should be

mount from the inside, see picture.

• The fan is used for transportation of “clean” air, mea-

ning not intended for fire-dangerous substances,

explosives, grinding dust, soot, etc.

• The fan is equipped with an asynchronous external

rotor induction motor with maintenance-free sealed

ball-bearings.

• The capacitor has finite lifetime and should be ex-

changed after 45.000 hours of operation (about 5

years) to secure maximum function. Defective capa-

citor can cause damage.

• To achieve maximum life time for installations in

damp or cold environments, the fan should be ope-

rating continuously.

• The fan can be installed outside or in other damp

environments. Make sure that the fan-house is equ-

ipped with drainage.

• All fans are as standard, single phase 230V, 50 Hz

and 220V, 60 Hz. Other voltages/frequencies on

request.

• The fan can be installed in any position.

8

INSTALLATION

This directions for use contains following products:

CK 100, CK 125, CK 150, CK 160, CK 200, CK 250 and CK 315

DESCRIPTION

ENGLISH