OTC Tools 3182 User manual

3182

Digital Battery Load Tester

Test Time: 10 seconds Max Time: 15 seconds

Digital 130 Amp Battery Load/Alternator Tester

Load Switch

OPERATING INSTRUCTIONS

2

When Working on Vehicles

• Always wear approved eye protection.

• Always operate the vehicle in a well-ventilated area. Do not inhale exhaust

gases—they are very poisonous!

• Neversmokeorhaveopenamesnearvehicle.Vaporsfromgasolineandcharging

batteriesarehighlyammableandexplosive.Alwayskeepareextinguishersuitable

forgasoline/electrical/chemicalreshandy.

• Alwayskeepyourself,tools,andtestequipmentawayfromallmovingorhotengine

parts.

• Neverlaytoolsonvehiclebattery.Youmayshorttheterminalstogether,causing

harmtoyourself,thetools,orthebattery.

• Always turn ignition key OFF when connecting or disconnecting electrical

components,unlessotherwiseinstructed.

• Keep away from engine cooling fan. On some vehicles, the fan may start up

unexpectedly.

• Neverleavevehicleunattendedwhilerunningtests.

• AlwaysmakesurethevehicleisinPark(automatictransmission)orNeutral(manual

transmission)andthattheparking brakeisrmlyset.Blockthedrivewheels.

• Alwaysfollowvehiclemanufacturer’swarnings,cautions,andserviceprocedures.

Additional Precautions When Testing

• Discharged batteries will freeze. Store batteries above 32°F (0°C) or maintain

batteriesinachargedcondition.

• TheBatteryLoadTesterbecomeshotduringtest.Allowittocoolbetweentests.

Thedisplaybeginsdimmingwhenthetesterisnotallowedtocool.Repeateduse

intheoverheatedconditioncandamagethetester’selectronics.

• Lead-acid batteries contain sulfuric-acid as the electrolyte.The electrolyte is

extremelycorrosiveandevolvesoxygenandhydrogenduringcharging,whichcan

igniteandcauseanexplosion.Haveventilationandkeepamesandsparksaway

fromchargingbattery.Followthemanufacturer’schargingprocedures.

• Ifelectrolytecontactsskin,immediatelyrinsewithwater.Ifelectrolytecontactseyes,

usheyeswithwaterandcontactphysician.Whenhandlingbatteries,weareye

protection,chemicalresistantglovesandprotectiveclothing.

DISCLAIMER!

Duetoinherentdangersassociatedwithautomotivemaintenanceprocedures,

themanufacturerandallpartiesinvolvedwiththedistributionand/orsaleof

thisequipmentwillnotbeheldliableorresponsible,eitherwhollyorinpart,

foranyinjury,damageorclaimsresultinginitsperformanceortheuseofthe

instructionscontainedinthismanual.

SAFETY PRECAUTIONS

3

Battery Load Tester

The3182DigitalBatteryLoadTesterisahand-held,diagnostictoolusedtotest12V

(volt)and6Vlead-acidtypeautomotivebatteries.A10-secondtestdeterminesthe

conditionofthebattery:Good,WeakorBad.Furthertestingwillidentifypossible

problemsinthechargingandstartingsystems.Testscanbeperformedonfully

orpartiallychargedbatteriesbyinspectingtheelectrolyteoropen-circuitvoltage

andadjustingthevaluesfortemperaturesotherthan70°F(21.1°C).

• Iftheelectrolyteisaccessible,measureitsspecicgravitywithahydrometer.

Thespecicgravityreadingshouldbe1.225orhigherat70°F(21.1°C).For

every10°F(5.6°C)above/below70°F(21.1°C),add/subtract0.004to/fromthe

reading.

• Theopen-circuitvoltageshouldbeatleast12.45Vat70°F(21.1°C).

TheBatteryLoadTestercontainsafour-characterLCD(liquidcrystaldisplay)to

displaybatteryvoltage,aswitchtoapplythetestloadandaredLEDthatisused

toindicatetheconditionofthealternator.Thetesterispoweredbythebattery

undertest.

CAUTION!

• Test procedures and information provided in this manual are intended

as general guidelines for engine tune-up and adjustments only. Consult

the applicable vehicle service manuals for all specic tests.

• Before testing, read and follow all safety precautions.

• Do not activate and hold the load switch for more than 15 seconds.

This will overload the tester resulting in damage and void the warranty.

Test Preparation

Multi-Battery Systems

Inallmultiplebatterysystems,allbatteriesmustbetestedseparately.Batteries

may be connected in series, parallel or a combination of both. Only batteries

connectedinseriesmayremainconnectedduringtest.See Figure 1.

Forseriesconnections,allbatteriesareconnectedfromthenegative(-)terminal

ofonebattery,tothepositive(+)terminaloftheother.Onlythenegativeterminal

oftherstbatteryandthepositiveterminalofthelastbatteryaretobeconnected

tothevehicle.Anynumberofbatteriesmaybeconnectedinaseries.However,

each battery must be tested separately.

Forallotherconnections(paralleloracombinationofparallelandseries),the

batteries mustbedisconnectedandelectricallyisolatedfromeachother.

TO VEHICLE POWER TO VEHICLE GROUND

POS NEG POS NEG POS NEG

Figure 1 Multi-Battery Test Conguration

4

Vehicle Battery

1.TurnignitionkeyOFF;notintheACCESSORIES

position (Figure 2).EngineneedstobeOFFand

all electrical loads must be removed from the

batteryforpropertesting.Ifloadsstillexist,refer

tothevehiclesoperatorandservicemanual.

2.Ifbatteryisbeingcharged,thenstop,turncharger

OFFanddisconnectclampsorleads.Thebattery

cannotbetestedwhilebeingcharged.

3.Theconnectionsmustbecleanandmustmake

goodcontacttoachievecorrecttestresults.

4.On side-post type batteries, install terminal stud adapters. These are not

included,butareavailableatmostautomotivepartsstores.

Battery Temperature

The most accurate test results will be obtained when battery temperature is

at approximately 70°F (21.1°C). If testing battery between 70°F (21.1°C) and

40°F(4.4°C),add0.1voltforevery10°F(5.6°C)below70°F.Iftestingabattery

between70°F(21.1°C)and100°F(37.8°C),subtract0.1Vforevery10°F(5.6°C)

above70°F(21.1°C).

Load Test

1.Connect the tester’s Black

clamptothenegative(-)battery

terminal and the Red clamp to

thepositive(+)batteryterminal

(Figure 3).Makesurebothjaws

makegoodcontact.Ifrequired,

rock clamps back and forth to

improve connection.

2.TheLCDdisplaywillturnonand

displaythebatteryvoltage.Thebatterymustbeatleast75%chargedbefore

conductingtheLoadTest.At70°F(21.1°C),thevoltageshouldbeatleast12.45V

(or6.23Vfora6Vbattery).Remembertoadjustvoltagefortemperaturesother

than70°F(21.1°C).

CAUTION!

• The Battery Load Tester becomes hot when applying the load.

Allow tester to cool between discharges; about 2 minutes. In warm

temperatures, allow more time to cool. If overheating occurs, the LCD

might temporarily become dim. After cooling down, the tester’s LCD

will return to normal.

• Do not activate and hold the load switch for more than 15 seconds.

This will overload the tester resulting in damage and void the warranty.

Figure 2 Engine OFF

Figure 3 Battery Connections

5

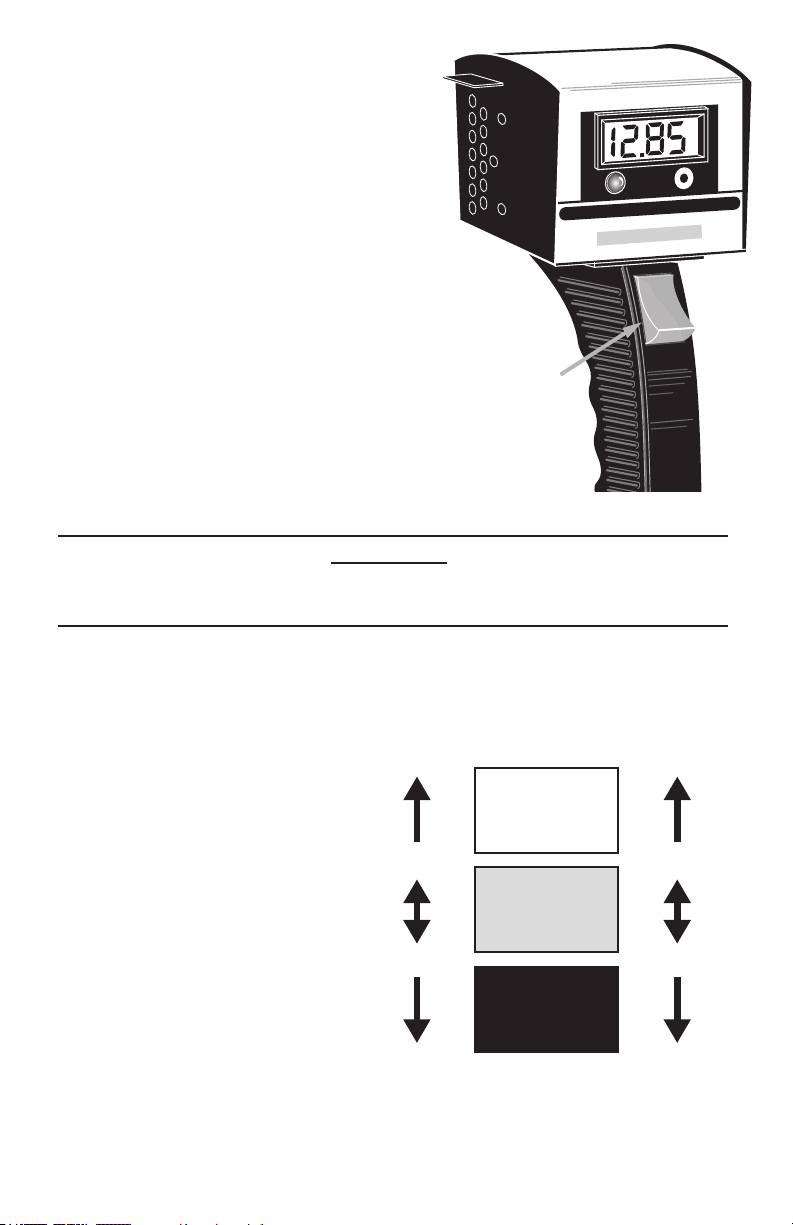

3.PressandholdtheLOAD SWITCHfor

10seconds.RefertoFigure 4.

4.Observe the voltage on the LCD and

note the value. Release the LOAD

SWITCHimmediatelyafterreadingthe

display.

5.Disconnect the Red clamp from the

batteryandthentheBlackclamp.

6.Figure 5showstherangefora500CCA

(Cold-CrankingAmperage) battery

tested at 70°F (21.1°C). For batteries

ratedatotherCCAvalues,subtract0.1V

forevery100CCAbelow500CCAfrom

thevaluesshowninFigure 5.Add0.1V

forevery100CCAabove500CCA.

IfthevoltageisintheWEAKregion,then

thebatteryisprobablydischargedand

needstobechargedbeforetesting.

• Disconnecttesterandchargebattery;

followbatterychargermanufacturer’s

instructionsforchargingprocedures.

WARNING!

Charging a battery with a bad cell may cause severe personal injury and

damage to vehicle and/or equipment.

• Disconnectcharger,reconnecttesterandretest.Ifthevoltageremainslow,

thenthebatteryisnotacceptingachargeandshouldbereplaced.

Test Results

GOOD - means the battery is in

good condition and should start

the vehicle in any environment.

WEAK - Indicates the battery is

dischargedandrequirescharging.

Chargebatteryandthenretest.

• IfbatterytestsWEAKasecond

time,thiscouldindicateoneor

more cells are bad and battery

mustbereplaced.

• If battery reads GOOD, the

battery was not suciently

chargedduringthersttest.

BAD - Indicates the battery is

deeply discharged and requires

acompletechargeorthebattery

isbadandrequiresreplacement.Checkthefollowing(onpage6)andretest.

Test Time: 10 seconds Max Time: 15 seconds

Digital 130 Amp Battery Load/Alternator Tester

Load Switch

Load Switch

Figure 4 Load Switch and Display

Figure 5 500 CCA Test Results at 70°F (21.1°C)

GOOD

WEAK

BAD

10.00V

6.10V 3.05V

5.00V

12V Battery 6V Battery

Table of contents

Other OTC Tools Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started