Table of Contents

Specifications..............................................................................................................3

General information..................................................................................................4

Safety information........................................................................................................4

Use of hazard information............................................................................................ 4

Precautionary labels....................................................................................................5

Certification..................................................................................................................5

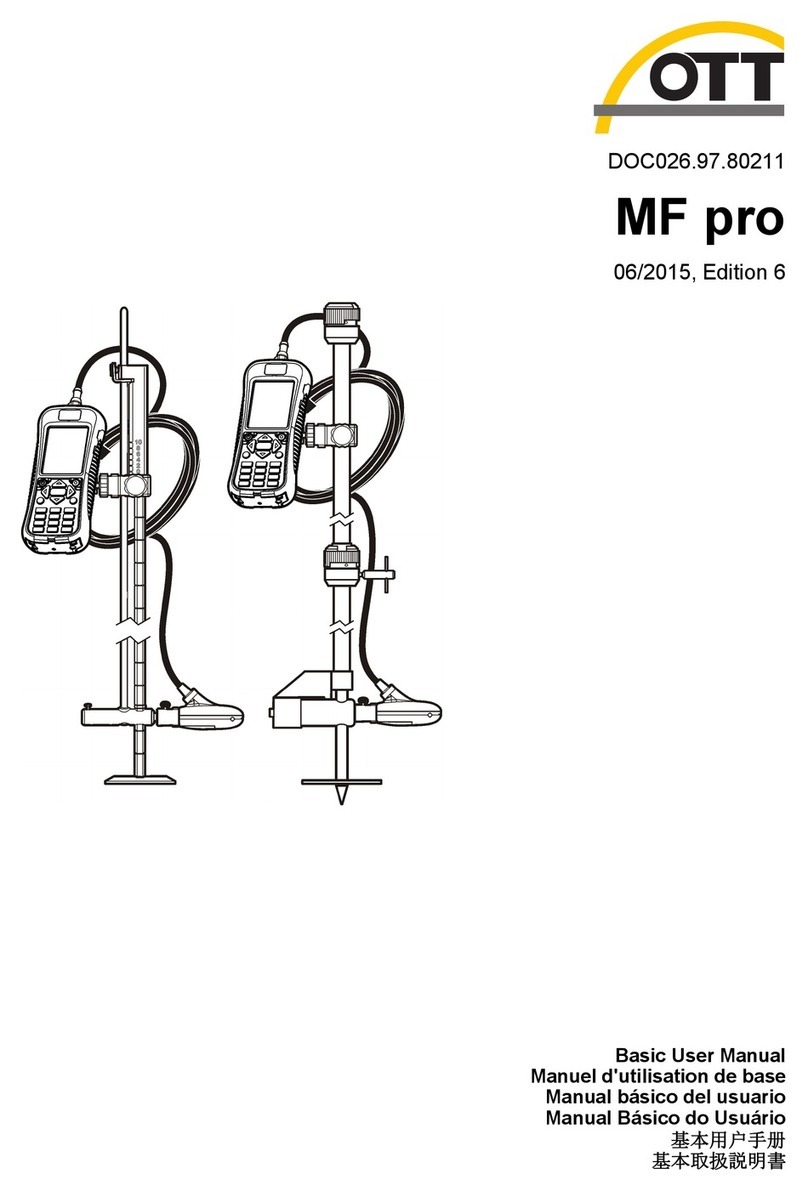

Product overview.......................................................................................................6

System components....................................................................................................6

About the sensor..................................................................................................8

Temperature compensation.................................................................................. 8

Installation.....................................................................................................................8

About the power supply and battery............................................................................8

Battery specifications ........................................................................................... 9

Charge the battery................................................................................................9

Connect the sensor cable to the handheld unit...........................................................9

To disconnect the sensor...................................................................................10

Attach the handheld display unit to the wading rod...................................................10

Attach the sensor to a wading rod.............................................................................12

Operation.....................................................................................................................12

Turn the handheld unit On and Off............................................................................12

Display screen...........................................................................................................13

Operating key icons ..................................................................................................13

Menu navigation and data entry................................................................................14

Display symbols ........................................................................................................14

Main Menu ................................................................................................................15

System settings.........................................................................................................15

Advanced settings ....................................................................................................16

Upgrade firmware......................................................................................................17

Performing measurements..................................................................................18

Station set up.............................................................................................................18

Angle of flow.......................................................................................................19

Quality control............................................................................................................19

Adjust quality thresholds..................................................................................... 20

Quick quality checks..................................................................................................21

Internal quality check.................................................................................................22

Calibrate the pressure cell (depth calibration)...........................................................22

Turn the depth sensor on or off..........................................................................23

About sensor offsets..................................................................................................23

Perform a single point measurement.........................................................................24

Velocity and discharge measurement methods.........................................................24

Methods for velocity measurement..................................................................... 24

Methods of discharge calculation.......................................................................26

Measurement settings menus.................................................................................... 28

Measurement settings [1/3] ...............................................................................28

Measurement settings [2/3]................................................................................28

1