2 3JADE X FULL SERVICE

SERVICE OVERVIEW

This manual will guide you step by step performing a full service to your

Jade X. Please follow each instruction carefully to achieve the best and

safest results.

*Always wear your safety gear while working on suspension products.

We care about you, make sure you wear your safety glasses and

protective gloves while servicing DVO Suspension Products.

WARNING: We recommend that you have your DVO suspension serviced by a qualied bicycle mechanic. Servicing DVO

suspension requires knowledge of suspension components, as well as the use of specialized tools and lubricants/fluids.

Failure to follow the procedures outlined in this service manual may cause damage to your component and void the

warranty.

WARNING: Always use genuine DVO parts and proper service methods when maintaining your DVO Suspension product.

Improper service, or use of aftermarket replacement parts with DVO Suspension may cause the product to malfunction,

resulting in SERIOUS INJURY OR DEATH.

WARNING: Modication, improper service, or use of aftermarket replacement parts with DVO Suspension may cause the

product to malfunction, resulting in SERIOUS INJURY OR DEATH. DO NOT modify any part of a fork or shock, including the

fork brace (lower leg cross brace), crown, steerer, upper and lower leg tubes, or internal parts, except as instructed herein.

Any unauthorized modication may void the warranty, and may cause failure or the fork or shock, resulting in SERIOUS

INJURY OR DEATH.

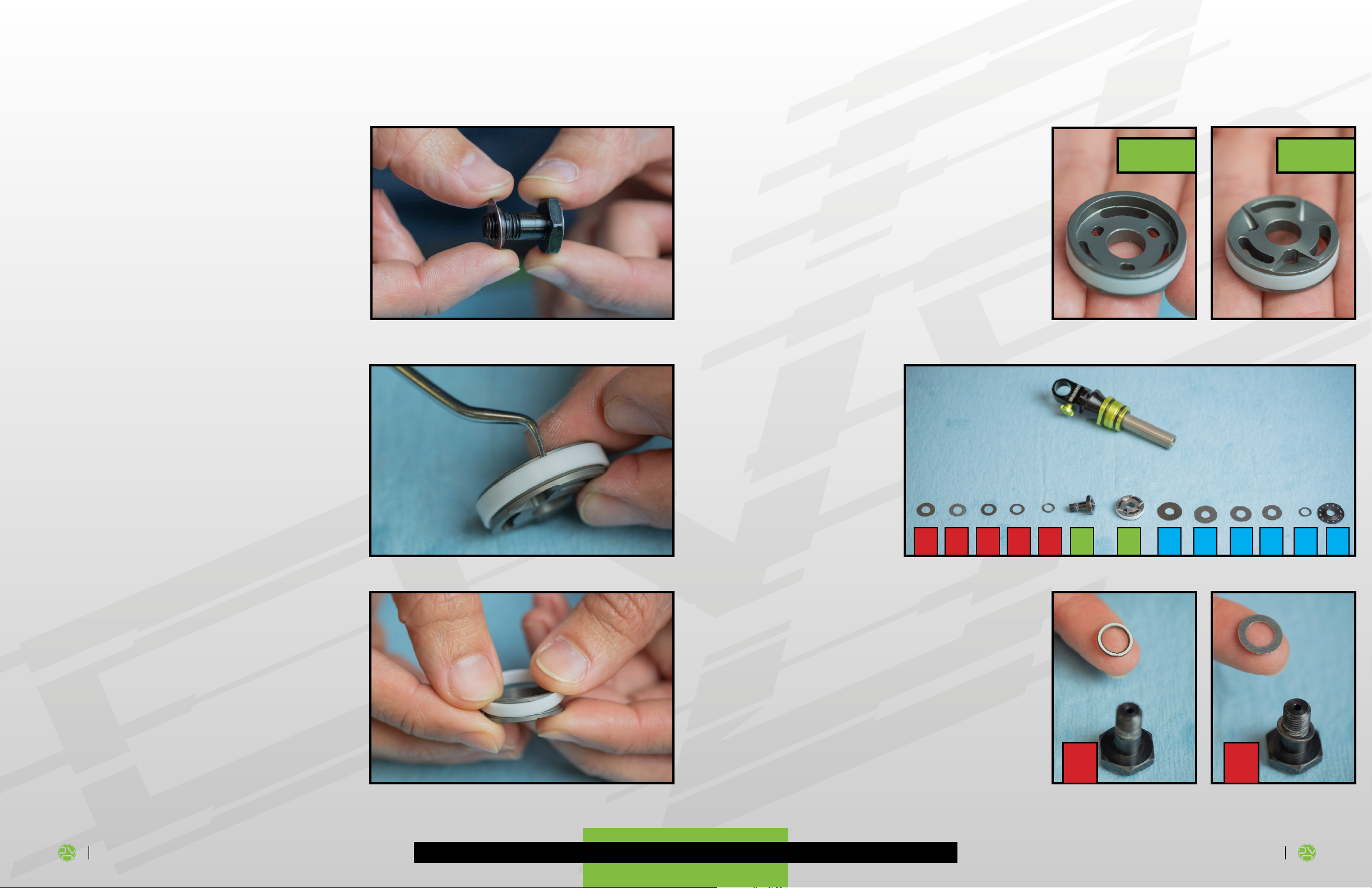

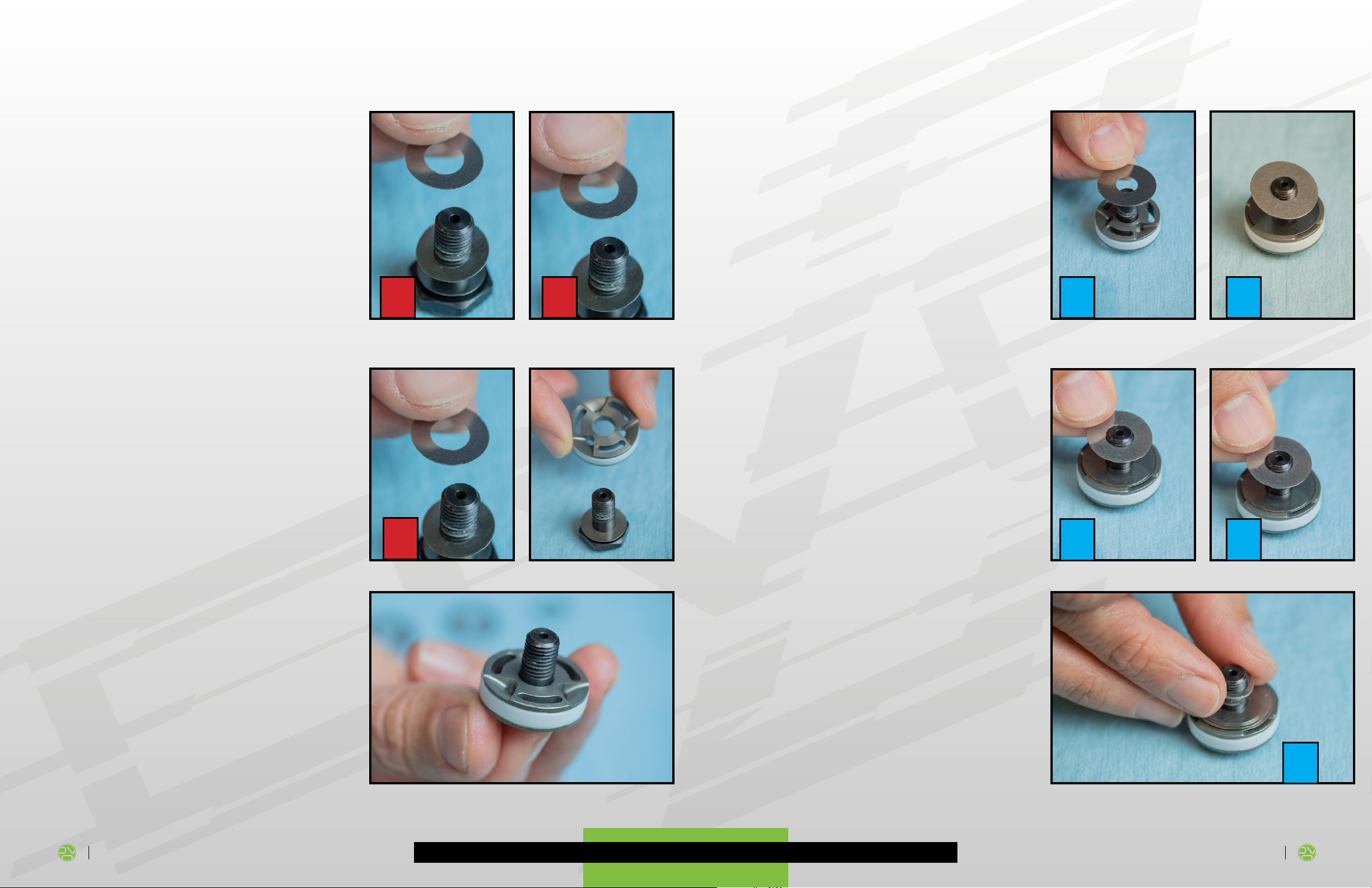

Tools Needed For Service:

• Allen Key Set

• Shaft Clamps

• Vice

• Adjustable Wrench

• 24mm socket

• Torque Wrench

• Kniplex or Pliers

• Pick

• Valve Core Remover

Fluids & Cleaner Needed For Service:

• Safety Glasses

• Clean, Lint Free Rag

• 2.5 wt suspension oil. (no maxima)

• Suspension Cleaner or Alcohol

• Shock Pump

• Loctite 242 BLUE

Recommended Service Interval:

• Full Service .......................100 Hours of Ride Time

WEAR SAFETY GEAR!