570 mm

172 mm

545 mm

130 - 136 mm

91 mm

Page 1

-Standard main rotor diameter

-Standard main blade length

-Main Grip Clamping

-Standard tail rotor diameter

-Standard tail blade length

-Tail Blade Clamping

-Weight

-Maximum motor size

-Maximum battery size

Chapter 1 - Specifications

Chapter 2 - Important Notes

Chapter 3 - Required Tools for Assembly

Chapter 4 - What's Inside The Box

Chapter 5 - Tail Assembly

Chapter 6 - Boom Assembly

Chapter 7 - Carbon Frame

Chapter 8 - Align and Lock Frame Panel

Chapter 9 - Motor Installation

Chapter 10 - Pinion selection and rpm

Chapter 11 - ESC Installation

page 1

page 2

page 3

page 4

page 5 - 7

page 8 - 9

page 10 - 12

page 13

page 14

page 15

page 16

INDEX

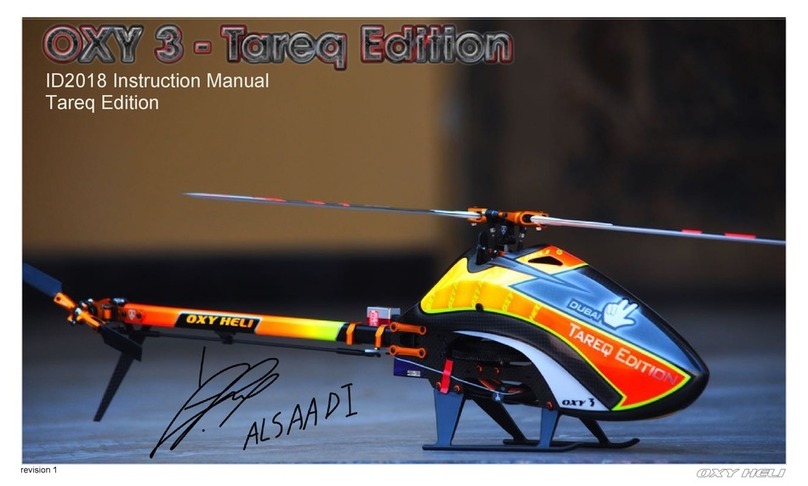

SPECIFICATIONS

: 570mm (with 255mm blades).

: 255mm.

: M2 / 5.6 mm root.

: 130-136mm.

: 47 - 50mm.

: M2 / 3.5 mm root.

: 450g (ready to fly excluding batteries)

: diameter 28mm.

: length 76mm, height 35mm, width 37mm, weight 180gr

Chapter 12 - Flybarless Installation

Chapter 13 - Transmission Assembly

Chapter 14 - Belt Tension & Adjustment

Chapter 15 - Head Assembly

Chapter 16 - Servo and FBL System Start Up

Chapter 17 - Servo Installation

Chapter 18 - Servo Rod and Landing Gear Installation

Chapter 19 - Flight / Maintenance

Chapter 20 - Adjustment Servo with Leveler

Chapter 21 - Flybarless Head System Installation

Chapter 22 - Exploded View

Chapter 23 - Spare Part

page 17

page 18 - 21

page 22

page 23 - 25

page 26

page 27 - 29

page 30

page 31

page 32 - 33

page 34 - 35

page 36 - 39

page 40 - 43

- Inside Box 02 you will find the instruction manual in PDF format on cd rom.

- Visit the Oxy Heli web site www.oxyheli.com to download the latest version of the manual.

- In the same box you will also find your serial number card. Please take a moment to visit the Oxy Heli web site and follow the

instructions to register your helicopter and serial number.

- It is important you take few minutes to register your helicopter and serial number with us. This is the only way to be in contact

with us to receive news, promotional information and technical tips.

- We will also choose five serial numbers each year that will win a discount coupon worth 200USD each to spend at the Oxy Heli

or Lynx Heli web sites.

- Thank you for your purchase, and we wish you the best enjoyment with your new Oxy 3 Helicopter.

VERY IMPORTANT NOTE:

Chapter 1, Specifications