INDEX

Chapter 1 - Specifications .....................................................................................................................................................................................................................................................................................

Chapter 2 - Important Notes ....................................................................................................................................................................................................................................................................................

Chapter 3 - Required Tools for Assembly ...............................................................................................................................................................................................................................................................

Chapter 4 - What's Inside The Box .........................................................................................................................................................................................................................................................................

Chapter 5 - Pinion Selection & RPM .......................................................................................................................................................................................................................................................................

Chapter 6 - Tail Assembly .......................................................................................................................................................................................................................................................................................

Chapter 7 - Main Frame Assembly .........................................................................................................................................................................................................................................................................

Chapter 8 - Align and Lock Frame Panel ................................................................................................................................................................................................................................................................

Chapter 9 - Transmission Assembly .......................................................................................................................................................................................................................................................................

Chapter 10 - Belt Tension & Adjustment .................................................................................................................................................................................................................................................................

Chapter 11 - Main Rotor Assembly .........................................................................................................................................................................................................................................................................

Chapter 12 - ESC Installation .................................................................................................................................................................................................................................................................................

Chapter 13 - Flybarless Installation ........................................................................................................................................................................................................................................................................

Chapter 14 - Servo & Servo Rod Prepareration .....................................................................................................................................................................................................................................................

Chapter 15 - Cylic Servo Installation ......................................................................................................................................................................................................................................................................

Chapter 16 - Tail Servo Installation ........................................................................................................................................................................................................................................................................

Chapter 17 - Landing Gear & Battery Installation ...................................................................................................................................................................................................................................................

Chapter 18 - Main & Tail Blades Installation ...........................................................................................................................................................................................................................................................

Chapter 19 - Adjustment Servo with Leveler ..........................................................................................................................................................................................................................................................

Chapter 20 - Exploded View ...................................................................................................................................................................................................................................................................................

page 2

page 3

page 4

page 5 - 6

page 7

page 8 - 13

page 14 - 18

page 19

page 20-21

page 22

page 23-25

page 26

page 27

page 28

page 29

page 30

page 31

page 31

page 32-33

page 34-37

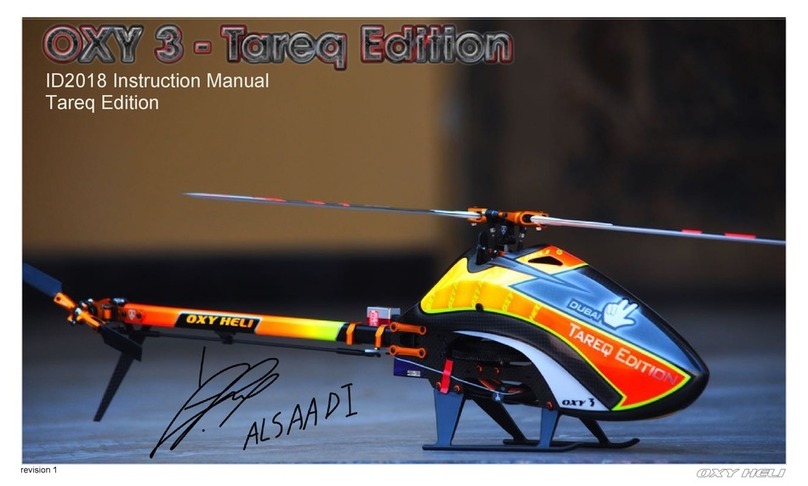

page 1