1-7

English

Français

ARABIC Deutsch

Italiano

Русский Español

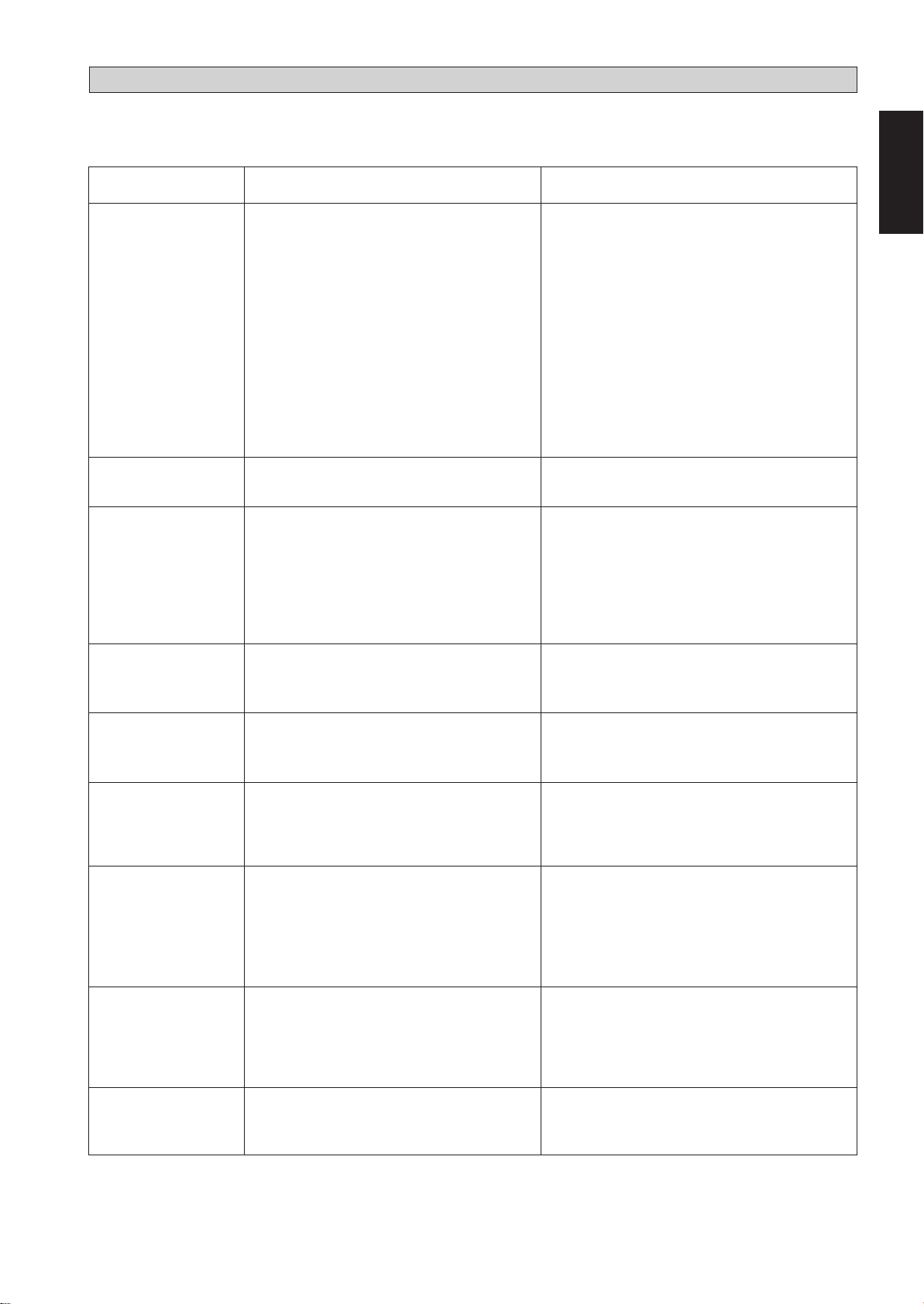

TROUBLE SHOOTING

If any malfunction occurs, immediately switch off the power supply to the unit, and contact a local dealer if necessary. Some

simple trouble shooting tips are given below.

SYMPTOMS POSSIBLE CAUSES REMEDIAL ACTION

1. Compressor does

not start.

2. Fan does not work.

3. Air cooled mini

chiller does work,

but cools

insufficiently.

4. PCB display ‘CO’.

5. PCB display ‘PO’.

6. PCB display ‘FL’.

7. PCB, display ‘HP’.

8. PCB display ‘LP’.

9. PCB display ‘E3’.

* No power supply.

* Fuses blown or automatic circuit break-

down open.

* Thermal relay tripped.

* Defective contactor or coil.

* Unit is stopped because safety device has

tripped.

* Loose wires.

* Compressor faulty.

* No power supply.

* Fan motor faulty.

* Thermostat setting too high.

* Condenser coil dirty.

* Obstacle blocking air inlet or outlet of the

unit.

* Insufficient refrigerant in the system.

* Improper water flow rate.

* Water source contains contamination.

* Compressor thermal relay tripped.

* Terminal loose.

* Pump thermal relay tripped.

* Terminal loose.

* Flow switch connection loose.

* Wrong terminal in flow switch.

* Water volume not enough.

* Flow switch blade too short or too long.

* Discharged pressure too high.

* Overcharge.

* Coil dirty.

* Condenser Fan does not work.

* Expansion valve stuck in open position.

* Suction pressure too low.

* Undercharge.

* Gas Leak.

* Water flow rate too low.

* Antifreeze protection activated.

* Water flow rate too low.

* Bubble in the heat exchanger.

* Check power supply.

* Look for short circuit or grounded wires in

motor windings. Replace fuses and reset

circuit breakers when the fault has been

corrected. Check tightness and soundness of

all electrical connections.

* Reset the thermal relay and carefully monitor

units operation when it is restarted.

* Repair or replace.

* Determine the type of safety shut down and

correct the default before the unit is restarted.

* Check wire connections and tighten terminal

screws.

* Contact local dealer.

* Check power supply.

* Contact local dealer.

* Reset thermostat.

* Contact local dealer.

* Remove the obstacle.

* Contact local dealer.

* Contact local dealer.

* Contact local dealer.

* Reset the thermal relay and carefully monitor

units operation when it is restarted.

* Tighten terminal screws.

* Reset the thermal relay and carefully monitor

units operation when it is restarted.

* Tighten terminal screws.

* Tighten terminal screws.

* Change the terminal.

* Add water into the system.

* Replace flow switch.

* Resetthe pressure switch andobserve the units

operation when it is restarted.

* Contact local dealer.

* Clean the coil with chemical detergent.

* Contact local dealer.

* Replace it.

* Resetthe pressure switch andobserve the units

operation when it is restarted.

* Contact local dealer.

* Contact local dealer.

* Adjust the flow rate.

* Check the temperature setting.

* Adjust the flow rate.

* Increase the water volume.

IM-AC-050A (En) 6/21/02, 10:357