Page 1 / 38

CONTENT

1. INTRODUCTION ............................................................................................................................... 3

2. SAFETY MEASURES .......................................................................................................................... 4

2.1 SYMBOLS USED IN THIS MANUAL ........................................................................................... 4

2.2 SAFETY INSTRUCTION .............................................................................................................. 5

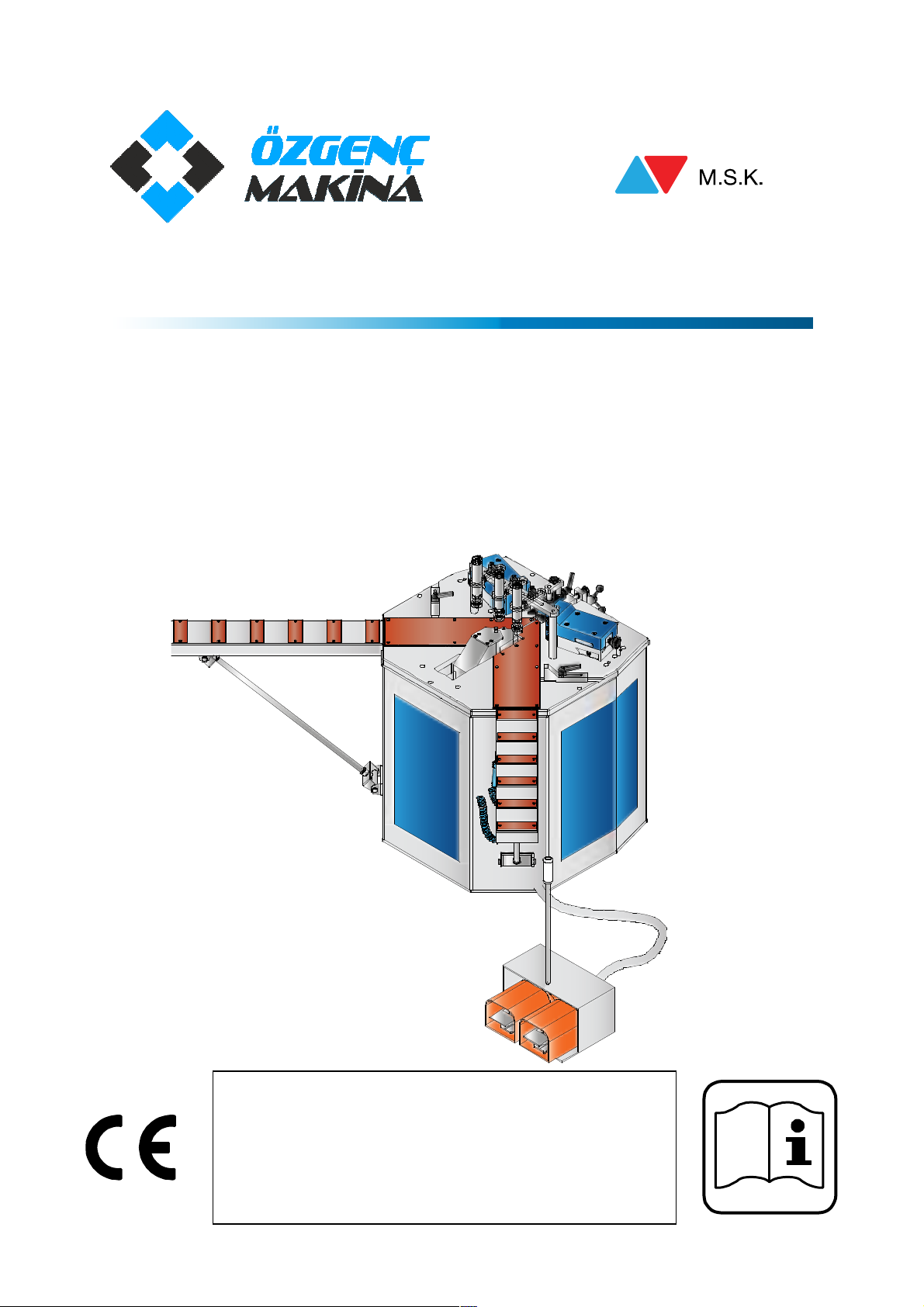

3. MACHINE DESCRIPTION .................................................................................................................. 7

3.1 GENERAL IEW ........................................................................................................................ 7

3.2 TECHNICAL DESCRIPTION ........................................................................................................ 8

3.3 TECHNICAL SPECIFICATIONS .................................................................................................... 8

3.4 PACKAGE CONTENTS ............................................................................................................... 8

4. INSTALLATION ................................................................................................................................. 9

4.1 TRANSPORTATION DIRECTIONS .............................................................................................. 9

4.2 REQUIRED WORKING AREA ..................................................................................................... 9

4.3 INSTALLATION AND MOUNTING ........................................................................................... 10

4.4 INITIAL CONNECTION ............................................................................................................ 10

5. OPERATING PRINCIPLE .................................................................................................................. 11

5.1 MACHINE BASIC SETTINGS .................................................................................................... 11

5.1.1 ADJUSTMENT OF CRIMPING HEADS POSITION ............................................................. 12

5.1.2 ADJUSTMENT OF CRIMPING HEADS POSITION ............................................................. 12

5.1.3 BLADE INSTALLATION .................................................................................................... 13

5.1.4 BLADES FABRICATION DRAWING .................................................................................. 14

5.1.5 ADJUSTING THE BLADES ................................................................................................ 15

5.1.6 ADJUSTING THE CORNER STOP ..................................................................................... 18

5.1.7 LOCK STOP ADJUSTMENT .............................................................................................. 19

5.2 MACHINE CONTROLS............................................................................................................. 20

5.3 SWITCHING THE MACHINE ON .............................................................................................. 21

6. SER ICING AND LUBRICATING THE MACHINE .............................................................................. 23

6.1 OIL REPLENISHER ................................................................................................................... 23

6.1.1 OILS RECOMMENDED FOR THE USE IN REPLENISHER ................................................... 23

6.2 REGULAR LUBRICATION POINTS............................................................................................ 24

6.2.1 OILS RECOMMENDED FOR REGULAR LUBRICATION ..................................................... 24

7. PNEUMATIC COMPONENTS .......................................................................................................... 25

7.1 AL E AND CYLINDER INSPECTION ....................................................................................... 25

7.2 ADJUSTING THE PNEUMATIC CYLINDER TRA EL SPEED ....................................................... 26

7.3 LUBRICATOR .......................................................................................................................... 26

7.3.1 WHAT LUBRICATOR IS NECESSARY FOR ........................................................................ 27