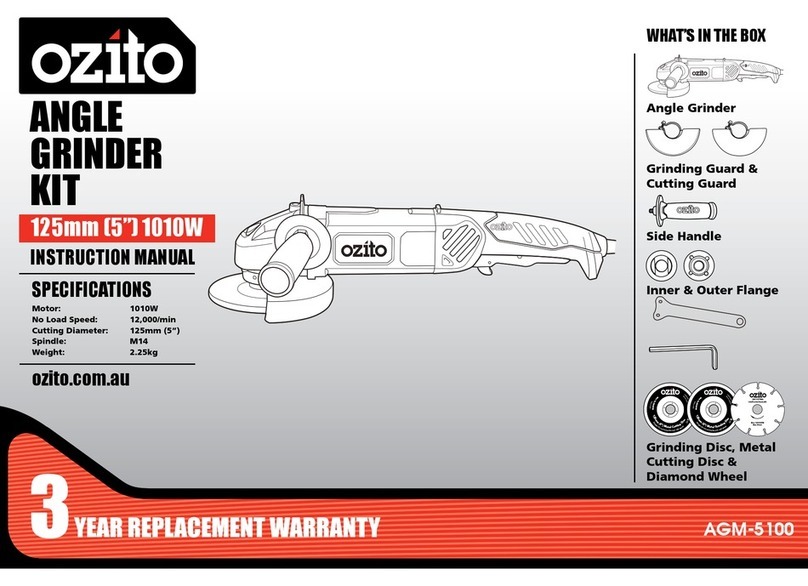

Assembling the Side Handle

The side handle should be assembled to the grinder prior to use. This is done by

screwing the threaded end of the handle firmly in to the metal gear case of the

grinder. There are three different positions the handle can be fitted to the grinder.

Choose the most appropriate position considering user comfort and the task at hand.

Adjusting the Safety Guard

Ensure the guard is fitted and at an angle which ensures it is between you and the

disc/wheel. The guard is there to protect you from dislodging objects at the work

piece and from accidental contact with the disc/wheel, of your hand, fingers or

other parts of your body. To adjust the guard, loosen the guard securing screw

using a screwdriver. Rotate the guard into the required position, then refasten the

screw. Ensure the guard is firmly secured prior to use.

Attaching and Removing Grinding Discs

•Inspect the grinding disc before fitting and during use to ensure it is not

deformed or cracked.

Note: Always ensure replacement discs/wheels maximum no load “RPM” speed

exceeds the no load speed marked on the rating label of this grinder. Use of a disc

or wheel which maximum no load “RPM” speed is less than the grinders is a hazard.

• Remove the outer threaded flange by hand if loose. If tight, depress the spindle

lock button at the top of the metal gear case and rotate the spindle to locate

the lock position. With the spindle locked and the spindle lock button still

depressed, use the pin spanner supplied to loosen the outer retaining flange

(threaded flange).

• Holding the angle grinder with the spindle facing upwards, ensure the inner

retaining flange (non threaded flange) is on the spindle and located correctly.

The two machined flat sections on one side of the inner retaining flange must

face the angle grinder and locate in the appropriate position on the spindle.

• Insert the grinding disc onto the angle grinder spindle with the disc label facing

the angle grinder. The hole in the disc should be located onto the spindle.

Ensure the hole in the disc locates and fits firmly into the ring section of the

inner retaining flange.

•Screw the outer retaining flange onto the spindle with the raised ring section

facing the angle grinder. This ring section must locate with in the hole in the disc.

•Tighten the outer retaining flange by locking the spindle as previously explained

then use the pin spanner to tighten the flange.

• Removal of the disc is conducted in reverse order to the above.

• Regularly check the disc retaining flange has not loosened during use.

Note: When fitting a cutting disc, the raised ring section on the outer retaining

flange should face away from the disc. The diamond cutting wheel should be fitted

the same as if fitting a cutting disc. The direction of the arrow on the wheel should

correspond with the arrow on the front of the metal gear case.

OPERATION (cont.)

8