FRONIUS TransSteel 3000c Pulse User manual

Other FRONIUS Welding System manuals

FRONIUS

FRONIUS TransPocket 1500 User manual

FRONIUS

FRONIUS VR 7000 User manual

FRONIUS

FRONIUS Robacta TSS /i User manual

FRONIUS

FRONIUS TPS 2700 MV Parts list manual

FRONIUS

FRONIUS MHP 700 S R/W/PAP/FSC User manual

FRONIUS

FRONIUS PullMig CMT User manual

FRONIUS

FRONIUS TransPocket 4000 CEL Guide

FRONIUS

FRONIUS TransPocket 4000 CEL User manual

FRONIUS

FRONIUS TPS/i Robotics TWIN Push User manual

FRONIUS

FRONIUS TPS/i Push User manual

FRONIUS

FRONIUS PullMig CMT User manual

FRONIUS

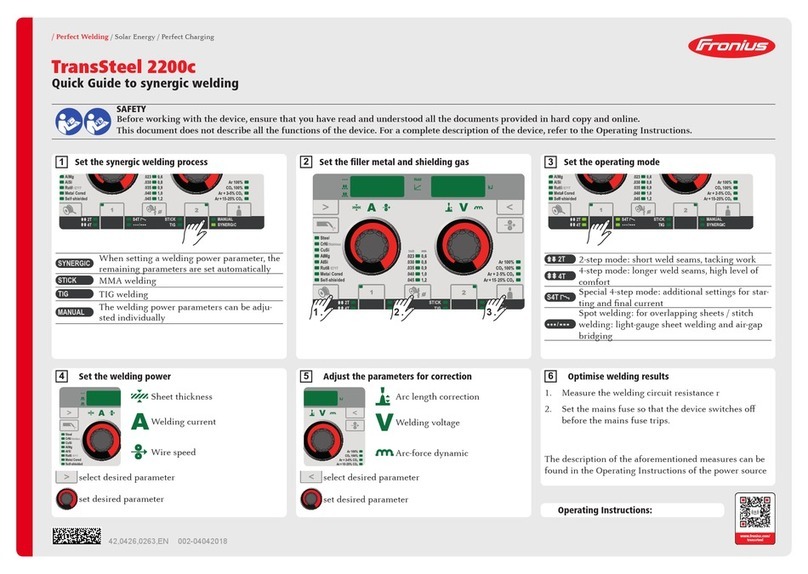

FRONIUS TransSteel 2200c User manual

FRONIUS

FRONIUS DeltaSpot Series Guide

FRONIUS

FRONIUS LaserHybrid Series User manual

FRONIUS

FRONIUS VST 247 User manual

FRONIUS

FRONIUS Profinet Robacta TX User manual

FRONIUS

FRONIUS KD Supply 2500 User manual

FRONIUS

FRONIUS CMT drive User manual

FRONIUS

FRONIUS Robacta Reamer V Comfort User manual

FRONIUS

FRONIUS Ignis 180 TIG User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual