8/SZ SERIES

OZONE SOLUTIONS

SECTION 4

MAINTENANCE AND REPLACEMENT PARTS

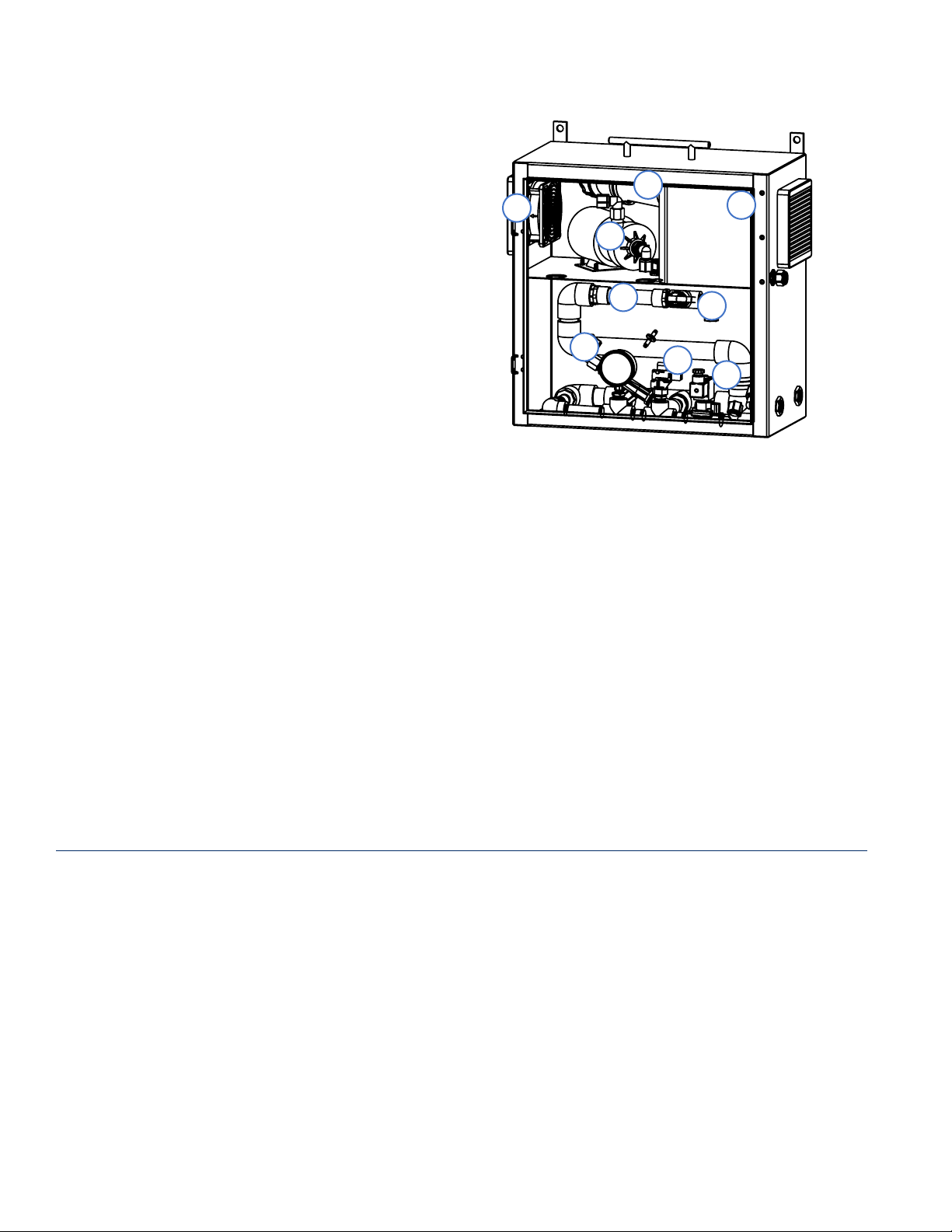

Issue Maintenance Action Part # Quantity

Air too moist Replace or regenerate air dryer

desiccant media

Desiccant 0.75 lbs.

Ambient ozone not being destructed Replace the ozone destruct media CBO-800M 115mm 2

Internal fan stopped working Replace fan Sunon Fan-ball bearing 1

Ozone Generator does not run Replace generator HG-1500 1

Blown Fuse Replace fuse 5A/250V Fuse 1

Check valve allows water backow Replace check valve CVLP-4 1

Pump not working Replace pump SinkZone Pump 1

If these actions do not solve the respective issues, contact the Ozone Solutions service department at 712.439.6880

for further troubleshooting and issue documentation.

WARRANTY

Ozone Solutions warrants all equipment assembled,

manufactured, and sold to be free from defects in

material and workmanship under normal use and

service for a period of one (1) year after date of sale to

the original purchaser.

Some products may have a specic warranty period

other than what is outlined in this document. For

such products, the manufacturer warranty will

supercede this warranty. Ozone Solutions will honor

the manufacturer’s warranty, but if and when advised

by the manufacturer, may have the customer deal

directly with the manufacturer. This warranty covers all

parts that are not outlined in a product maintenance

schedule. This warranty will be void if any piece of the

equipment is used in a manner other than what is

explicitly outlined in the product manuals.

If any part of the equipment manufactured by Ozone

Solutions proves to be defective during the warranty

period, please call Ozone Solutions at 712.439.6880,

Prior authorization is required before working on

or shipping a product back to us. Failure to get prior

authorization may result in denial of your claim. Once

authorized, you may return the defective equipment

to Ozone Solutions with the transportation charges

prepaid. If Ozone Solutions nds the equipment to

be defective, it will be repaired or replaced at our

discretion, free of charge, to the original purchaser

(F.O.B. factory).

This warranty shall not place any liability on Ozone

Solutions for any transportation charges, labor, or

cost for, or during the replacement of any parts. The

replaced part(s) or product will then continue the

original warranty duration. The replaced parts will not

start a new one (1) year coverage period. The purchaser

by acceptance of the equipment will assume all liability

for the consequences of its use or misuse by the

purchaser, employees, or others. This warranty shall

not apply to any piece of equipment, or part thereof

sold by this company which has been subject to any

accident caused in transit, alterations by unauthorized

service, negligence, abuse, or damage by ood, re, or

act of God.

This warranty shall constitute the entire warranty and/

or agreement between Ozone Solutions and the original

purchaser, and in lieu of all other warranties, expressed

or implied, either oral or written, including the warranty

of merchantability and tness for a particular use and

of all other obligations or liabilities on our part. Ozone

Solutions neither assumes nor authorizes any other

person or entity to assume for us any liability associated

with the sale of its products or equipment.

The term “original purchaser,” as used in this warranty,

means whom the product was originally sold to by Ozone

Solutions or by an authorized dealer. Ozone Solutions

reserves the right to make changes in its products

without notice. Because of this, Ozone Solutions is not

obligated to replace warranty defective part(s) and/or

product with the same original part or product.