2 | Page

Contents

MAIN FEATURES................................................................................................................................................. 3

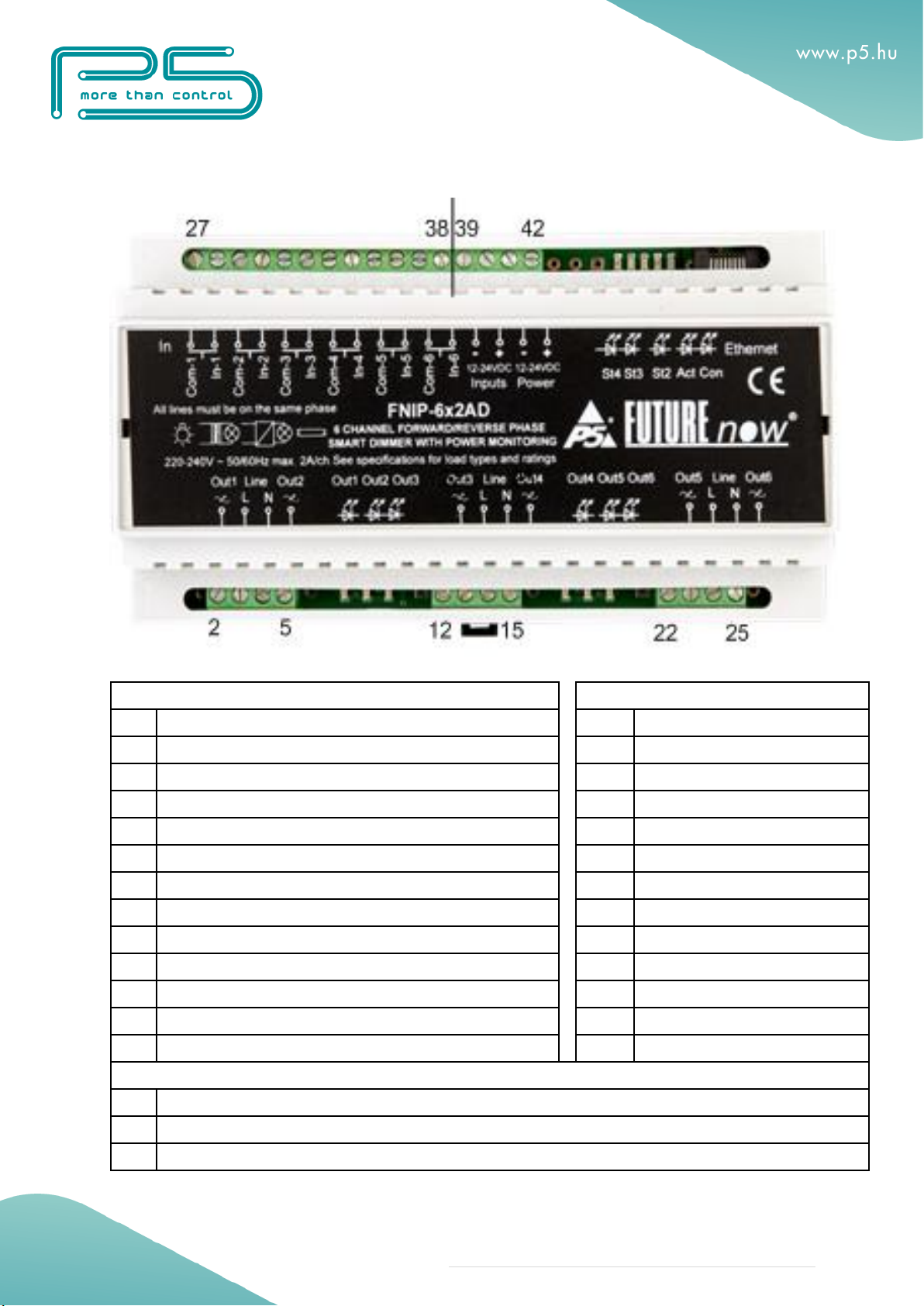

INSTALLATION.................................................................................................................................................... 4

Terminal connections.......................................................................................................................................... 4

Wiring................................................................................................................................................................. 6

Outputs................................................................................................................................................................ 7

Local inputs......................................................................................................................................................... 8

Status LED indicators ..................................................................................................................................... 9

Input status LEDs............................................................................................................................................ 9

Run LED......................................................................................................................................................... 9

Input power LED ............................................................................................................................................ 9

Communication LEDs................................................................................................................................... 10

Output status LEDs ....................................................................................................................................... 10

CONFIGURATION.............................................................................................................................................. 11

Configuration via the web interface.................................................................................................................. 11

Connecting to the web server of the module................................................................................................. 11

Network settings ............................................................................................................................................... 12

Users and user rights......................................................................................................................................... 14

Channel settings................................................................................................................................................ 15

Dim settings ...................................................................................................................................................... 16

Combining channels...................................................................................................................................... 17

Scenes ............................................................................................................................................................... 18

Firmware Upgrade ............................................................................................................................................ 19

OPERATION........................................................................................................................................................ 20

Operation via local inputs ................................................................................................................................. 20

Input modes....................................................................................................................................................... 20

Operation via the built-in web server................................................................................................................ 22

Operation via TCP ............................................................................................................................................ 24

TECHNICAL SPECIFICATIONS ................................................................................................................... 25

REFERENCES.................................................................................................................................................. 26

CONTACT DETAILS...................................................................................................................................... 26