7

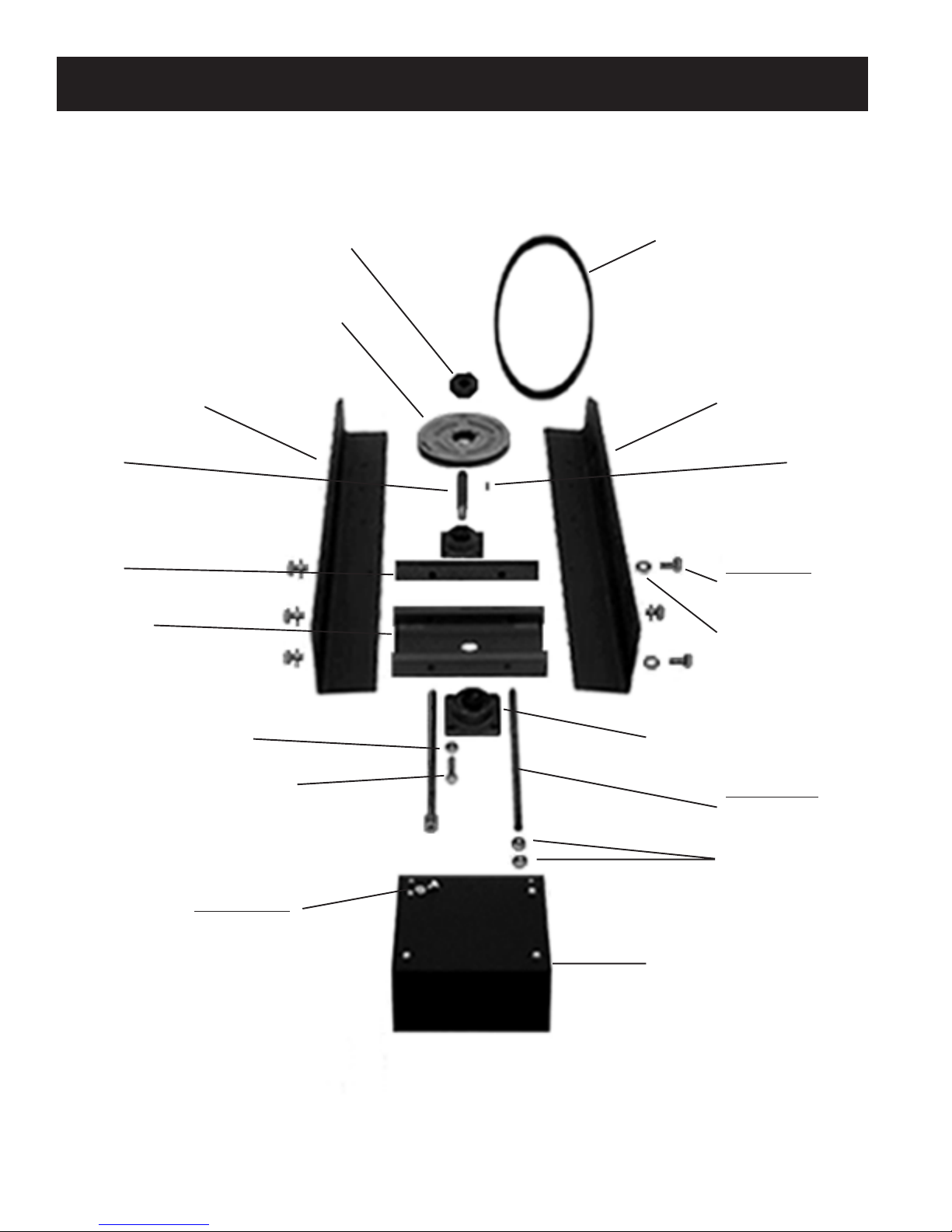

B. Changing the Drive Belt Continued.

4. Turn the 2 tension rods counter clockwise equal

turns until you can push the bearing hub plate to the

rear (3/4-inch socket).

5. Remove the old belt and install the new one.

6. Tension the new belt by reversing step #4. The

belt should be just tight enough to not slip or squeal.

Care must be taken not to over tension the belt. Over

tension will cause premature bearing wear.

7. Retighten the 4 bearing hub plate mounting bolts.

8. Replace the front cover.

C. CHANGING THEANGLE OFATTACK (PAD TO

FLOOR) & THE HEAD PRESSURE.

If the machine has been dropped or you notice a dis-

tinct increase in the torque during operation, this ad-

justment may be needed. For this operation, you will

need: a ¾-inch wrench, a new pad installed on the

machine, a framing level, a wood block and shims,

and a level floor

area on which to set the machine. The end results of

this operation should be a machine with framework

that sets slightly low in both the rear and on the right

side. The right frame should be 1/8-inch lower than

the left frame at the wheel bracket point. You may

measure the distance from the top of the axle plate to

the top of the main frame to establish this difference.

Th 1/8-inch variance from the left to the right is criti-

cal for level buffing and ease of operation. If the dif-

ference is increased (more than 1/8- inch), torque re-

lief will increase but level buffing will decrease; you

will shine harder on the right side of the machine than

the left. If the difference is decreased (less than 1/8-

inch), torque relief will decrease and level buffing will

increase. The machine will be harder to operate. When

you get it right, the machine will deliver good level

buffing with a minimum of operating effort.

1. Install a new pad onto the machine.

2. Place the machine onto a level floor area.

3. Remove the LP tank.

4. Place the wood block and shims under the tails of

the right and left main frames of the machine; enough

to slightly raise the wheels from the floor.

5. Loosen the right and left axle brackets, two bolts

each.

6. Level the left main frame with the framing level.

You will need to remove the wood shims as this is

done. Tap the wheel up or down as needed to main-

tain floor contact. The frame should be slightly low in

the rear (about ¼ inch below level at the tail).

7. When this measure is achieved, tap the left wheel

to the floor and tighten the mounting bolts.

8. Now measure the distance between the top of the

left wheel bracket and the top of the left main frame.

9. Subtract 1/8-inch from the measurement in step

#8. Set the right wheel bracket to this new mea-

surement.

10. Tighten all wheel bracket mounting bolts and re-

move the wood block and shims.

If the unit seems to over torque after a test run, you

may correct this problem by simply raising both wheel

brackets equal amounts. This adjustment changes the

angle of attack pad to floor and should be made in

small 1/8-inch increments. Always keep the right

frame 1/8-inch lower than the left at the wheel bracket

point.

If you desire to increase the head pressure of your

unit, simply move the right and left axle brackets to

the rear equal amounts. Make this move in ½ inch

increments. Test run the unit after each adjustment

until you reach the desired head pressure. If you find

that you have increased the head pressure and increased

the torque, the torque may be decreased by raising both

the right and left wheels equal amounts. The wheel

system on this unit is designed for the professional.

There are enough adjustments to make the machine

buff any way you want. The ability to control the head

pressure and angle of attack ate advantageous to level

buffing, ease of operation, and superior pad life.