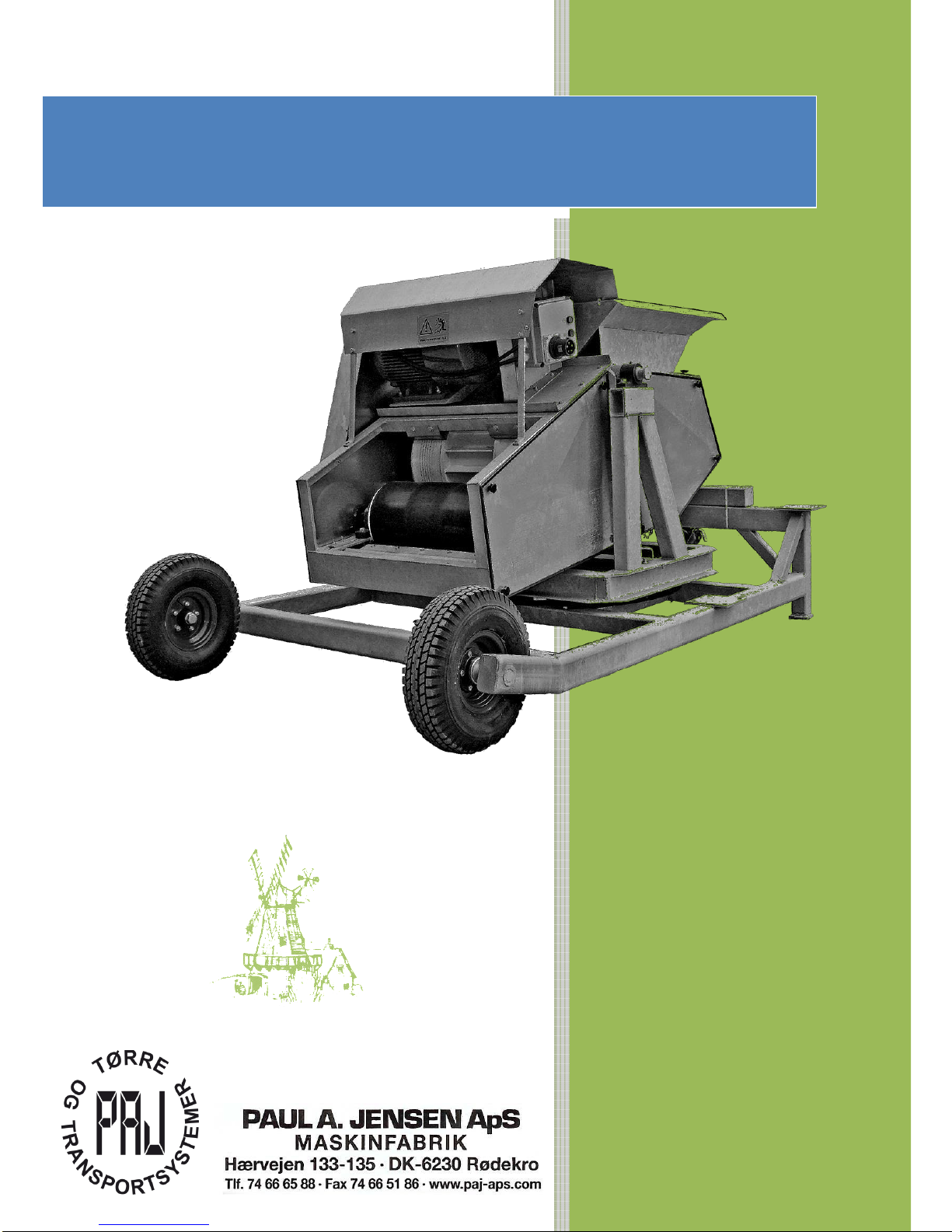

Operating manual

Introduction

This operating manual constitutes an important part of the supply and must be handed over to the owner. The

instructions are of great importance to operation and maintenance of the equipment.

The instructions concern safety, power supply and maintenance. We recommend keeping the operating manual

within reach.

Once a possible packaging has been removed, the equipment must be controlled for loose parts and

possibly visible errors. Transport damages must be noted directly on the consignment note. If, when

controlling, there is any doubt that the equipment is reliable, you should contact the supplier or the

producer.

Disposal of packaging

The packaging must be disposed of as laid down in the instructions. At free return of the packaging we will take care

of the disposal.

Important instructions for operation

To guarantee operation and safety of the equipment it is of great importance that the maintenance and

operation instructions are observed.

Prior to each cleaning, maintenance and repair you must always be sure that the power supply has been

switched off. This also goes for the automatism and the swing motor.

Equipment is produced and delivered according to class of protection IP55, unless otherwise demanded.

Delivery according to ATEX21 or 22 must expressly be mentioned in the offer.

Errors in the power supply (defect/loose cables and switches) or damages to the control box imply that the

equipment is immediately stopped. Operation must be continued only after competent control.

Maintenance and repair of the power supply must only be performed by an electrician. The guarantee lapses at

disregard.

Power supply must be equipped with a 63 A (as a minimum) fuse. In case

of a long standstill the power supply must be completely disconnected.

Prior to starting-up you must be sure that no persons are present in front of the equipment. There is a risk of

injury caused by thrown grain or manure remains.

Power data

T 2 is produced for conveyance of grain and granules with a specific weight of a maximum of 1000 kgs/m3

Transport capacity of grain 150 m³/h

Maximum throwing length up to 25 m

Maximum throwing height 8 m