OPERATING MANUAL CD 2000

Palas®GmbH, Karlsruhe, Version V002022014

Content

Important Notes for Operation of Corona Discharge Unit CD 2000! ........................................ 3

1. Check of delivery .................................................................................................................... 4

1.1 Checking of accessory equipment supplies...................................................................... 4

2. Safety conditions / Intended use ........................................................................................... 5

2.1 General safety conditions ................................................................................................. 5

2.2 Intended use ..................................................................................................................... 5

2.3 Responsibility of the operator .......................................................................................... 5

3. Short Operating Instructions.................................................................................................. 6

3.1 Connections ...................................................................................................................... 6

3.2 Switching-on Procedure.................................................................................................... 6

3.3 Switching-off Procedure ................................................................................................... 6

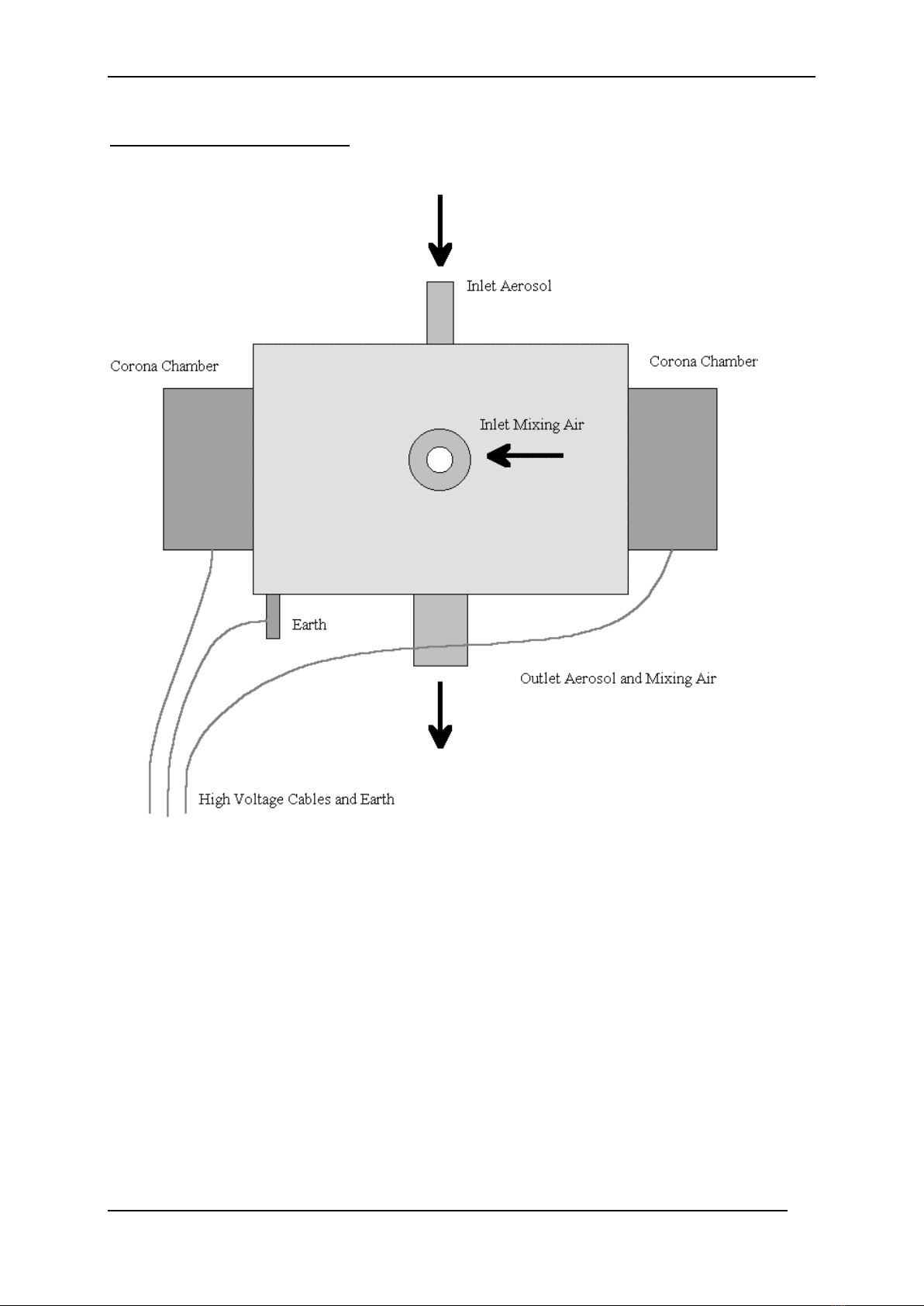

4. Function Principle ............................................................................................................... 7

5. Electrical Adjustment of Corona Ionization Chambers.......................................................... 8

5.1 Principle: ........................................................................................................................... 8

5.2 Procedure:......................................................................................................................... 8

5.3 Adjusting the external potentiometers with scale:.......................................................... 8

6. Malfunctions ........................................................................................................................ 10

6.1 FAQs ................................................................................................................................ 10

6.2 General............................................................................................................................ 10

7. Maintenance ........................................................................................................................ 11

8. Technical Data for Standard Equipment.............................................................................. 12

8.1 Electrical data.................................................................................................................. 12

8.2 Mechanical data (standard values)................................................................................. 12

9. Spare parts list / accessories list .......................................................................................... 13

9.1 The following replacement parts are available: ............................................................. 13

10. Transport, packaging and storage...................................................................................... 14

10.1 Packaging: ..................................................................................................................... 14

10.2 Storage: ......................................................................................................................... 14

10.3 Transport: ..................................................................................................................... 14

11. Disposal of the Discharge Unit CD 2000 ............................................................................ 15

12. Feedback form.................................................................................................................... 16