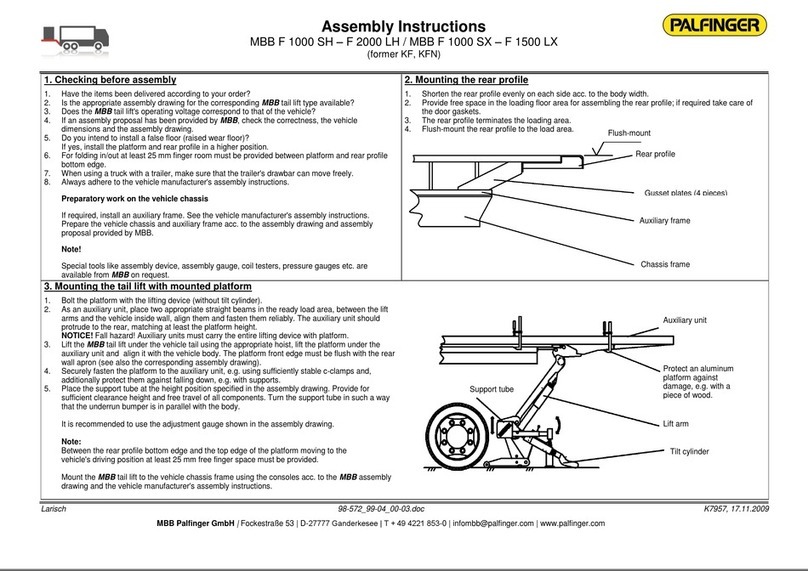

3. Installation of electrics

1. Refer to the corresponding C 500 VAN circuit diagram (see the Operating Instruction Manual

provided) and follow the vehicle manufacturer's assembly instructions.

2. Run the battery cable to the battery, shorten it if required and install the cable lug

3. Assemble the main fuse with the cable lug and connect it to the battery positive terminal.

4. Lay the controller cable through to the driver's cab. In the driver's cab, select the appropriate place

at the instrument panel, establish an electrical connection according to the C 500 VAN circuit

diagram and attach the control box.

5. If a control box already exists in the vehicle, connect the C 500 VAN according to the additional

circuit diagram. If necessary, order this circuit diagram from PALFINGER Tail Lifts.

6. Establish a ground connection according to the vehicle manufacturer's assembly instructions

Control unit for Control unit for

motor vehicle semitrailer and trailer

7. CAUTION! For DGRTR vehicles, connect the ground cable to the battery or according to the vehicle

manufacturer's assembly instructions.

8. The hand cable control may be operated from the marked position on the platform, only.

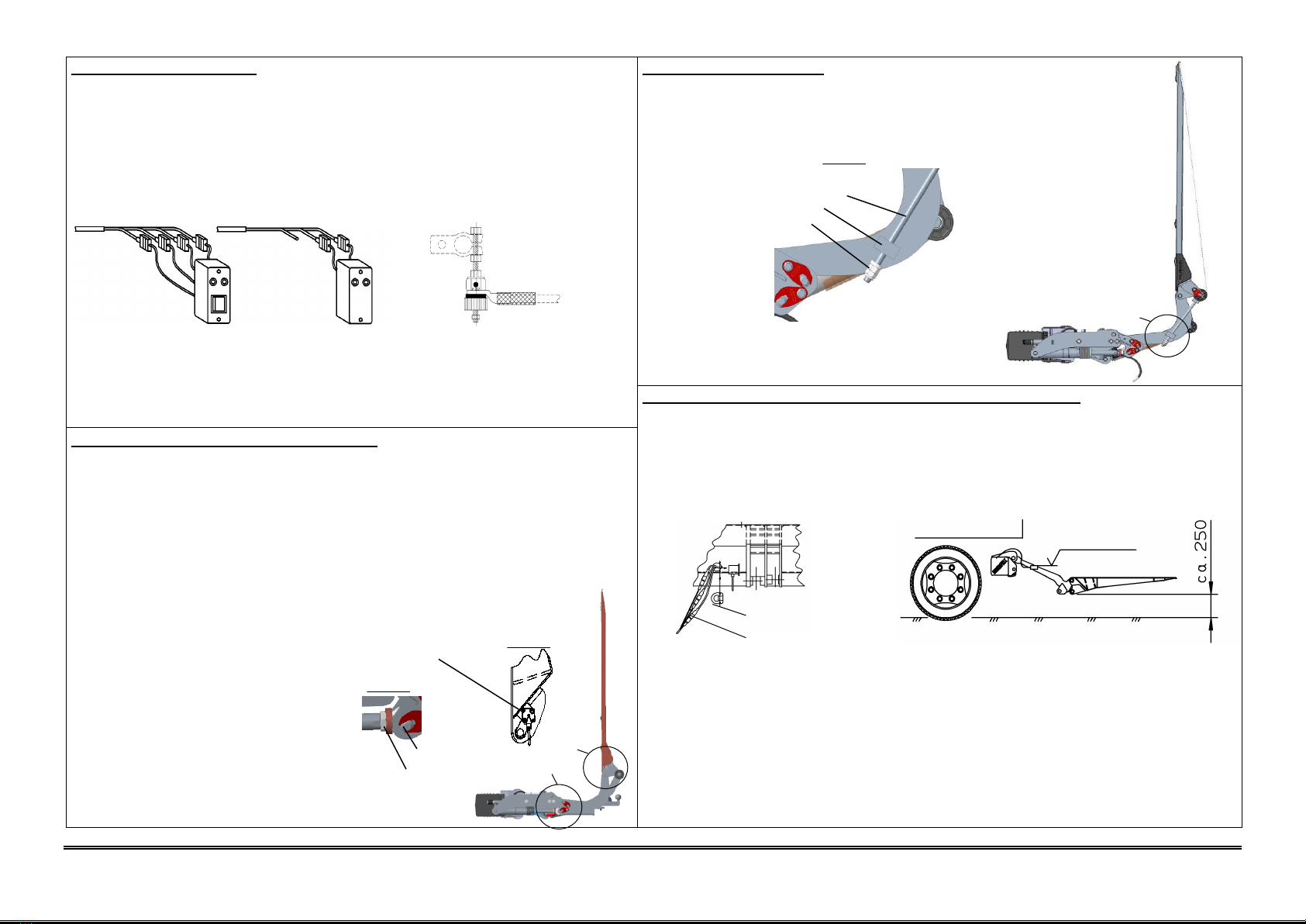

4. Assembly and adjustment - tilt cylinder

1. Turn the tilt cylinder's rod head until reaching the piston rod stop. Actuate the Open or Close control

switch to set the tilt cylinder to a length that allows you to bolt the cylinder to the platform. For this

purpose, hold down the tilt sensor b15/b16 with the cable. Pin platform with the tilt cylinder, secure

with the tab and secure with M12 screw. Tighten this to a torque of 75Nm.

2. Move the lifting device up to the height stop using the lifting cylinder. If required, remove the

auxiliary unit.

3. Attach the tilt sensor b15/b16, as seen in the diagram, to the dedicated platform strap on the right-

hand side so that the potting compound is oriented towards the outside.

4. Unscrew the drawbar nuts as far as possible.

5. Close the platform towards the vehicle body as far as possible (fully extend the tilt cylinder),

release the tilt cylinder by briefly actuating the "Open" pushbutton switch

and turn the piston rod

using an open ended wrench to close the

platform as far as possible until it is approx.

5cm from the vehicle body (doors).

NOTE! In this platform position

the tilt cylinder must be fully extended

to the stop.

CAUTION! The platform must not come in

contact with the vehicle body, which

may otherwise be damaged.

6. De-pressurise the tilt cylinder by opening the platform

and fasten the piston rod counter nut according

to the assembly drawing.

6. Adjustment and installation work prior to commissioning

1. Loosen the strain relief (plastic cap at the platform head profile). Pull the cable with the connector plug

for the foot control and Warnfix out of the platform (make sure that the cable length is sufficient) and then

reinstall the strain relief. Run the cable along the hydraulic hoses to the hydraulic unit. Use cable binders.

Connect the plug to the appropriate receptacle on the PCB according to the circuit diagram. Insert the

cable through the entry into the hydraulic unit housing and position the protection sleeve. Close the

hydraulic unit.

2. Close the platform to the body.

3. All cables installed must be carefully laid and securely fastened. Sufficient bending lengths must be

observed.

4. Lower the platform until reaching a level of approx. 250 mm above ground and set the switch b13 at the

torsion frame to its horizontal position. For this purpose, undo the switch fastening screw, re-tighten it

after the setup and fold back the locking plate.

5. Lift, lower, open and close the platform several times in order to bleed the cylinder. If required, adjust the

platform's horizontal position on the ground by turning the tilt sensor b16 accordingly.

6. Check the oil level with lowered platform and check that all screw connections established according to

the assembly drawing are tight. Perform an acceptance test according to the test data booklet and record

the test results in the test data booklet.