Trademarks & Intellectual Property

Pall and are trademarks of Pall Corporation.

Filtration. Separation. Solution. is a trademark of

Pall Corporation.

Copyright

The design of this equipment and all associated

documentation is copyright of Pall Corporation, 2018.

Reprints, even of extracts hereof, are permitted only if the

source is quoted and permission has been granted by Pall.

The main components, devices, arrangements, as well as

software, control and instrumentation equipment on all of

our machines are protected both at home and abroad by

patent applications, design registrations or copyright.

© Copyright

Pall Corporation

25 Harbor Park Drive

Port Washington, NY 11050

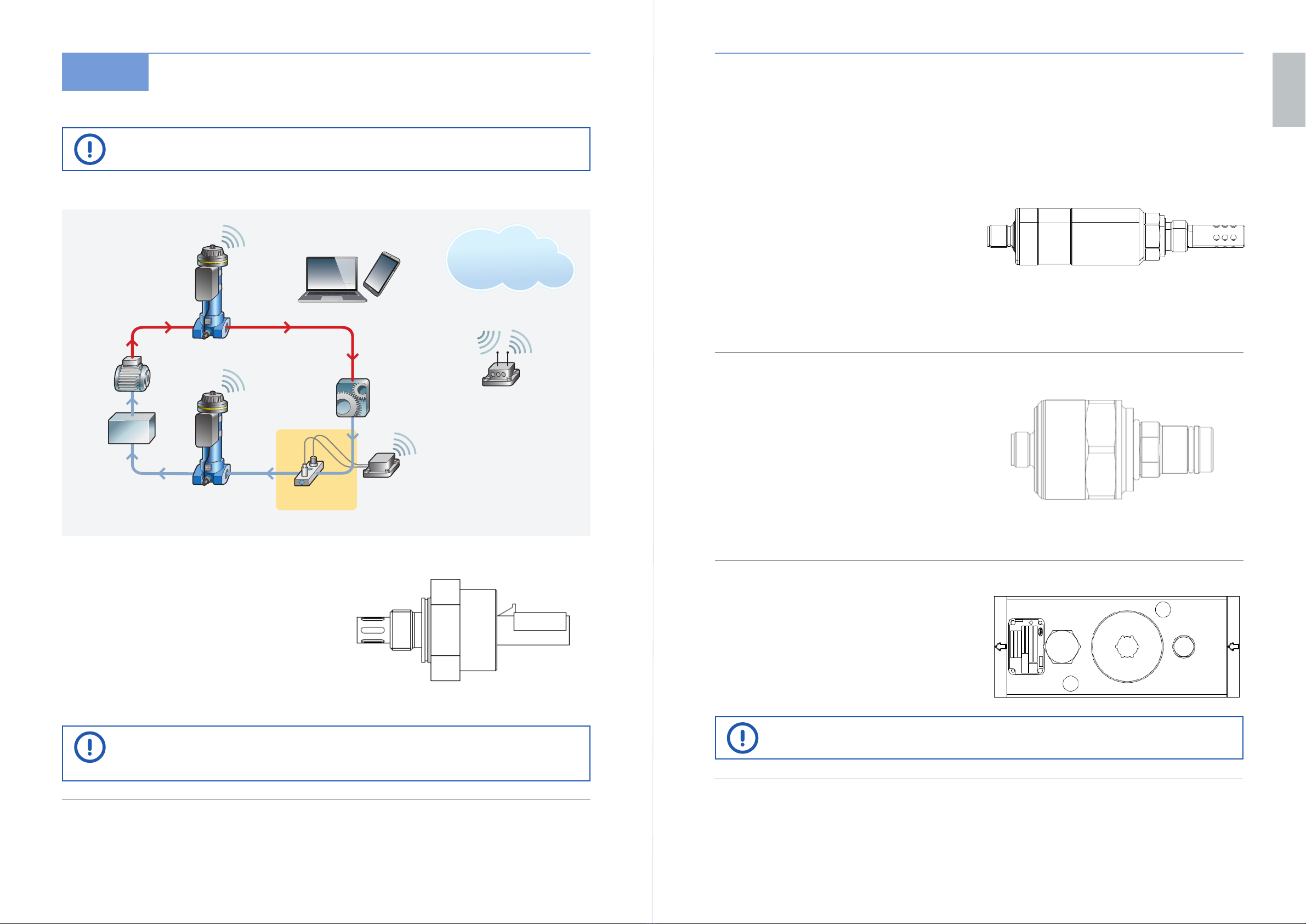

Connecting Utilities

To ensure the safe and efcient operation

of the equipment and adherence to

existing laws and regulations, only qualied

personnel should make utility connections.

Pall Corporation is not responsible for and

equipment warranties may be voided from

any damage or personal injury caused by

unqualied personnel performing utility

connections and/or installations.

Certications & Statements

FCC Statement

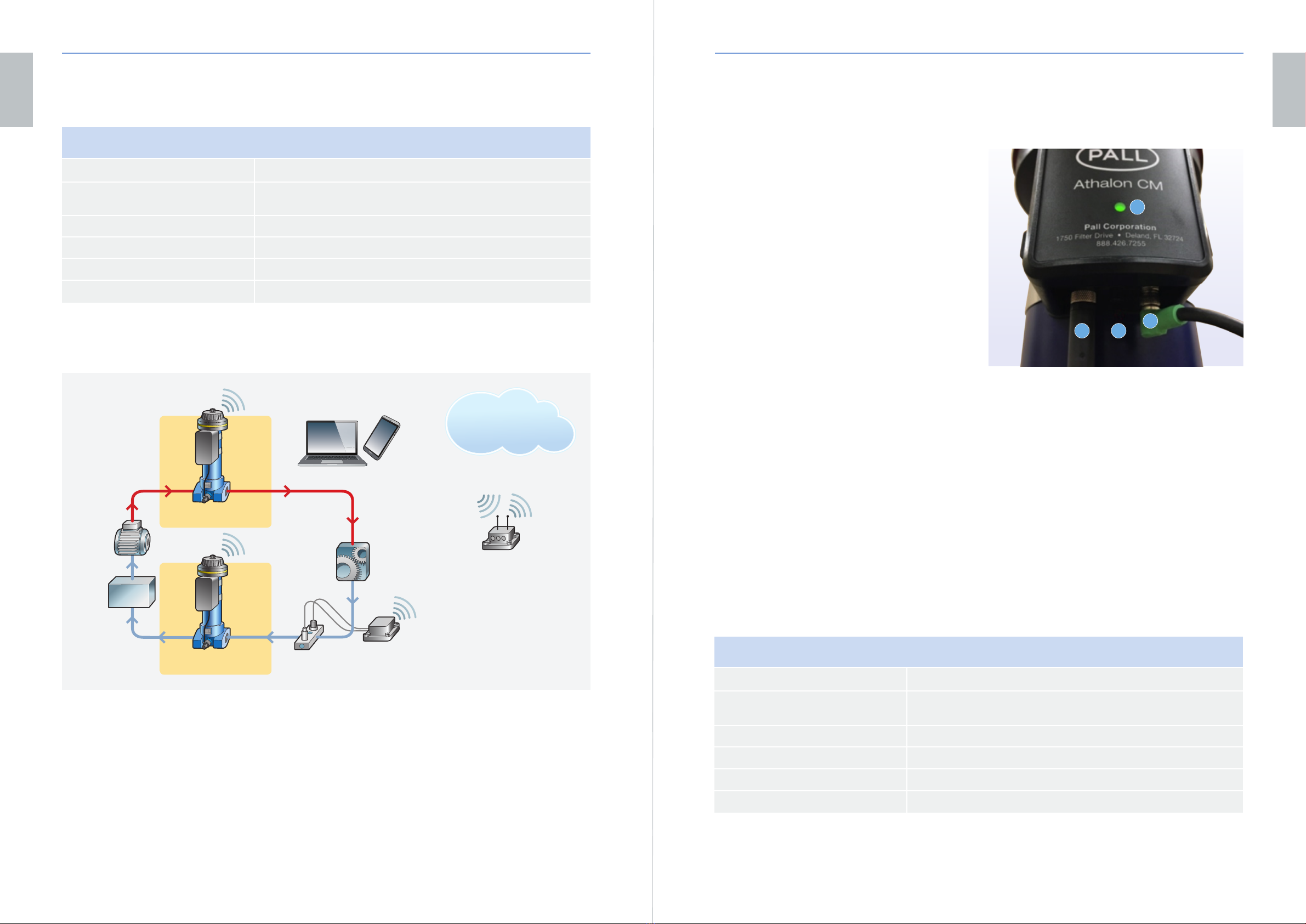

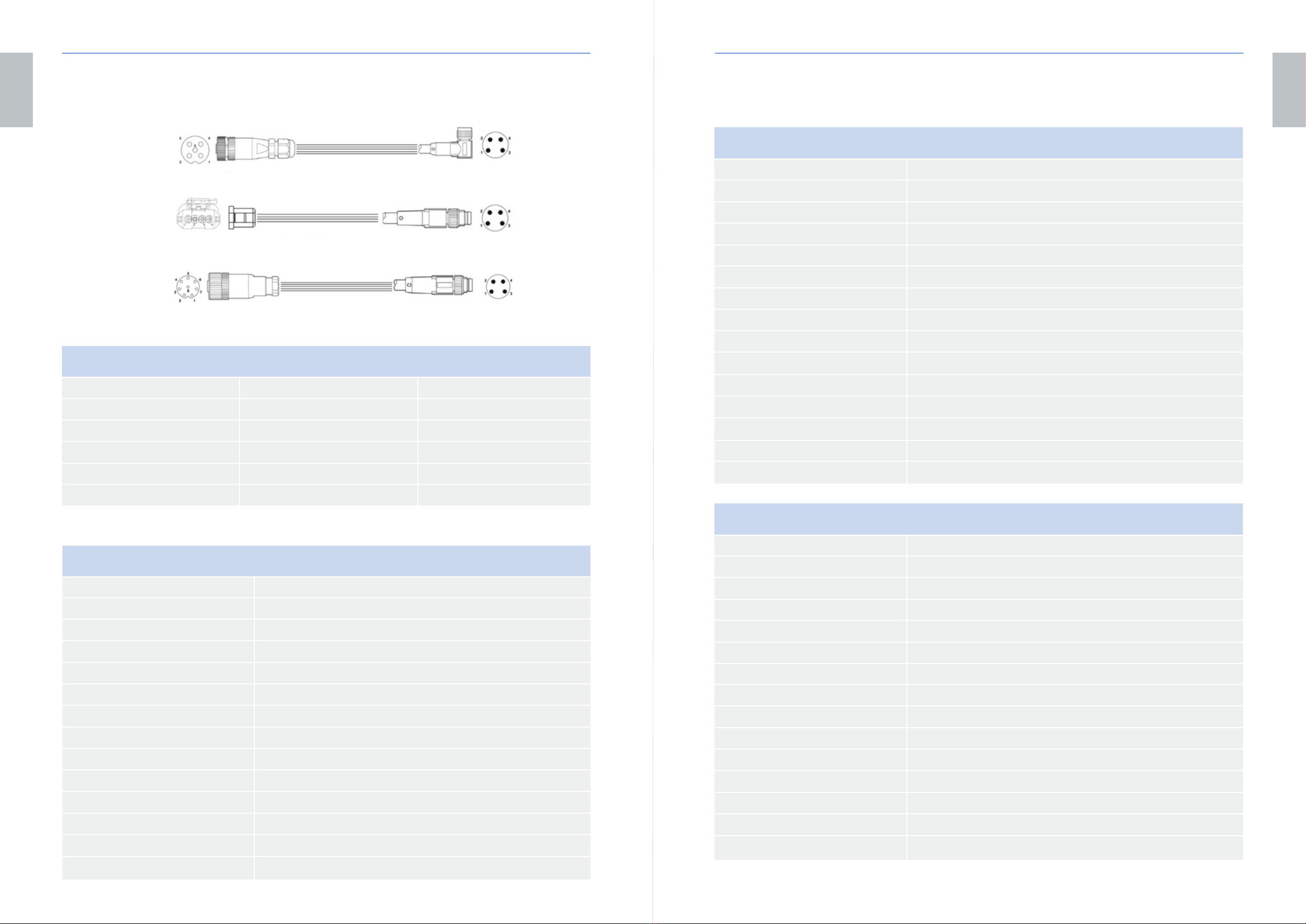

The Wi-Fi Gateway, Fluid Interface, and

Filter Housing comply with Part 15 of the

FCC Rules. Operation is subject to the

following two conditions: (1) these devices

may not cause harmful interference, and (2)

these devices must accept any interference

received, including interference that may

cause undesired operation.

These devices do not contain any user-

serviceable parts. Changes or modications

not expressly approved by Pall Corporation

could void the user’s authority to operate

the equipment.

Note: This equipment has been tested and

found to comply with the limits for a Class

A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed

to provide reasonable protection against

harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can

radiate radio frequency (RF) energy and, if

not installed and used in accordance with

the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential

area is likely to cause harmful interference

in which case the user will be required to

correct the interference at his own expense.

These devices use RF energy to

communicate. To reduce RF Exposure,

these devices must be installed in a manner

to ensure at least 20cm separation is

maintained between the device antenna

and the body of the user or nearby people.

ISED (Canada) Notice

These devices comply with Industry

Canada’s license-exempt RSSs. Operation

is subject to the following two conditions:

(1) these devices may not cause harmful

interference, and (2) these devices must

accept any interference received, including

interference that may cause undesired

operation.

CE (Europe) Notice

Hereby, Pall Corporation declares that

these devices are in compliance with the

essential requirements and other relevant

provisions of Directive 2014/53/EU.

UL Certication Statement:

Underwriters Laboratories has tested and

evaluated the Athalon®CM Gateway, Fluid

Interface and Filter Node(s) as Control and

Measuring Equipment and has issued a

Certicate of Compliance to:

•UL 61010-1, 3rd Edition, May 11, 2012,

revised April 29, 2016

•CAN/CSA-C22.2 No. 61010-1-12,

3rd Edition, revision dated April 2016

Reference Certicate No. 2017-8-25-

E479541 and Report E479541-D1000-1/

A0/C0-UL date 25 August 2017.

Athalon®CM User Manual

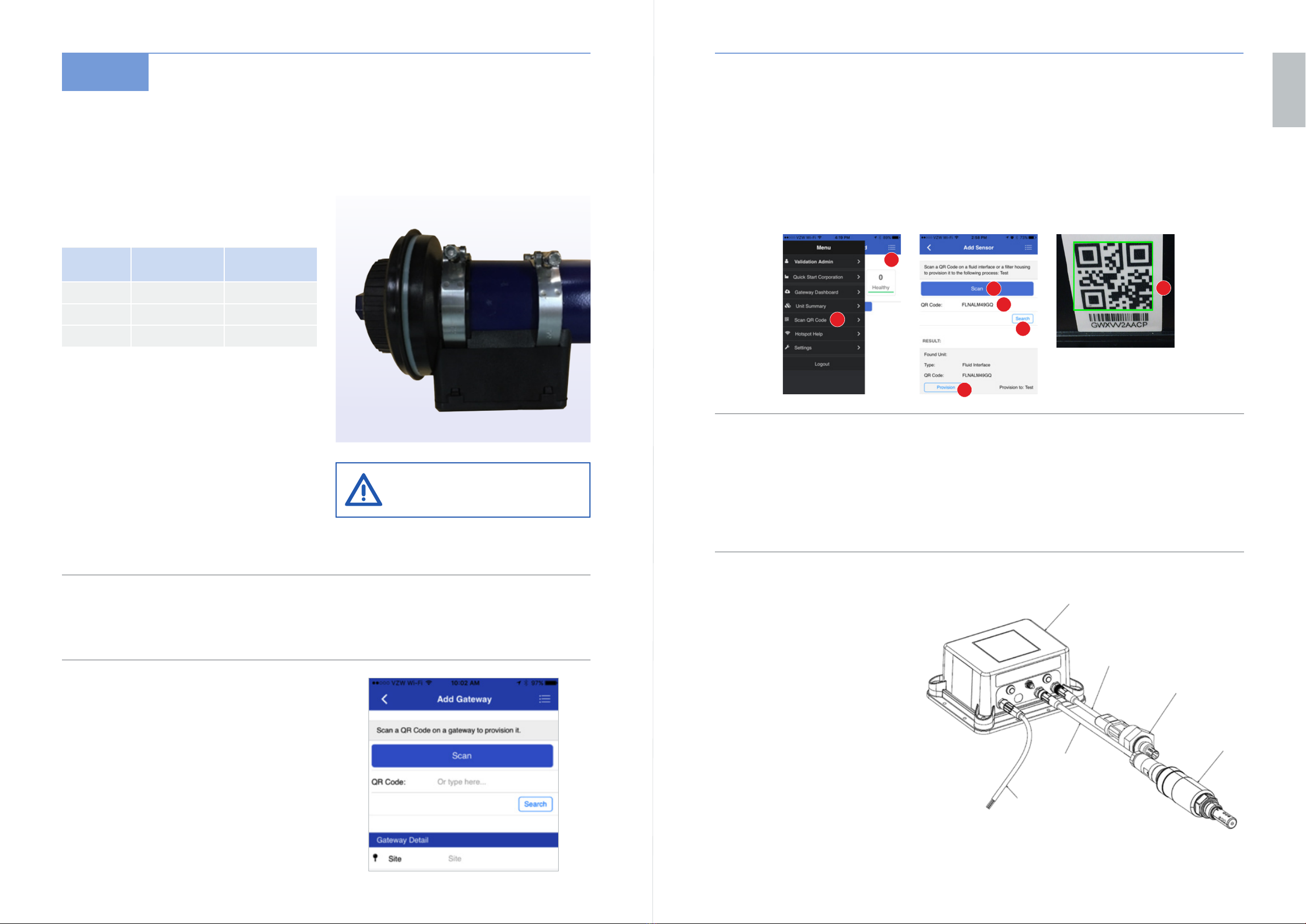

To ensure the safety of personnel during the

installation and operation of the Athalon®CM

system, the following symbols will help

identify important information regarding the

equipment.

WARNING:

These are instructions that draw

attention to the risk of injury or

death!

CAUTION:

These are instructions that draw

attention to the risk of damage

to the product, the process, the

equipment or the surroundings!

IMPORTANT:

These are instructions that draw

attention to information that will

aid installation, operation or

maintenance!

WARNING - ELECTRICAL HAZARD:

These are instructions that draw

attention to any potential

electrical hazards that could injure

personnel, the process or the

equipment!

Terms of Guarantee

The manufacturer is not liable for damage resulting

from: improper use, failure to observe this manual,

the employment of insufciently qualied personnel,

or unauthorised modications to the unit and unit

components supplied by Pall. In these cases the

manufacturer’s warranty / guarantee is rendered void.

CAUTION - IMPAIRMENT OF CORRECT

UNIT OPERATION WHEN USING

INCORRECT SPARE PARTS!

When using components that have not been approved,

correct operation of the unit can no longer be guaranteed.

Only use spare parts approved by Pall.

ENSURE THERE IS ADEQUATE

LIGHTING TO OPERATE EQUIPMENT.

OBSERVE LOCAL REGULATIONS FOR

FACTORY USE.

HEALTH AND SAFETY.

OBSERVE CAUTION WHEN HANDLING

FLUIDS AND PAY ATTENTION TO

INSTRUCTIONS OF SAFE USE IN THE

MATERIAL SAFETY DATA SHEET

AND COSHH REGULATIONS. WEAR

PROTECTIVE CLOTHING IF

PRESCRIBED; E.G. SAFETY GLOVES,

CLOTHING AND FOOTWEAR.

BE AWARE OF POSSIBLE DANGER

ASSOCIATED WITH HIGH OIL

TEMPERATURES AND EXPOSED METAL

SURFACES OF THE ATHALON®CM

HARDWARE.

DO NOT USE THE ATHALON®CM

HARDWARE IN AN EXPLOSIVE

ATMOSPHERE.

WARNING - ELECTRICAL HAZARD