Document #: 4100022 Revision: F Page #: 5 of 21

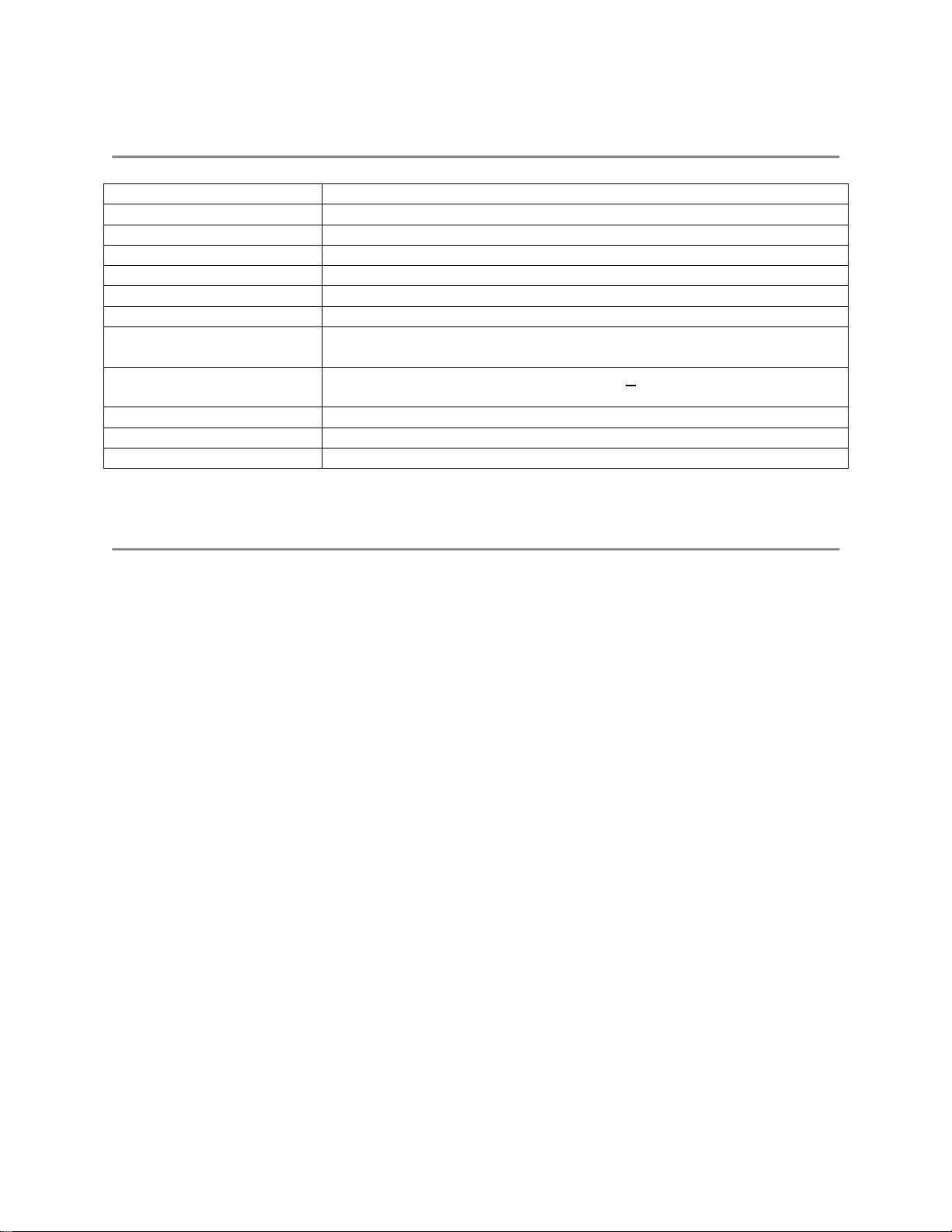

2. SPECIFICATIONS

Single Phase 115/230V AC 50/60 Hz, full load current 2.0/1.0 A

Less than 180 Watts at maximum speed

85% (non-condensing), *avoid condensation, * for indoor use

Not subject to continuous vibration or excessive impact. In

conformance with JIS C 60068-2-6, “Sine-Wave Vibration Test”

MAIN supply voltage fluctuations up to + 10% of the nominal

voltage

33 in x 16 in (84 cm x 41 cm)

41 in (104 cm), to top of handle

3. INTRODUCTION & PRINCIPLE OF OPERATION

The Magnetic Mixer disposable bag mixing system is based on a single-use mixing bag

containing a bottom mounted disposable magnetic impeller on a disposable bearing. The single-

use magnetic impeller includes a proprietary bearing assembly designed and composed to

control particulate generation. All the materials of the impeller/bearing assembly contacting the

fluid are non-metallic USP Class VI and ADCF. The Magnetic Mixer disposable mixing system

consists of an interchangeable magnetic drive unit and proprietary magnetic impeller based

mixing bags fitted into retaining tanks on either a universal portable dolly (30L –500L) or a floor

mounted tank support (500L –2,000L). The magnetic Drive Motor is coupled with the mixing

bag through a proprietary interface. The activation of the motor induces rotation of the in-bag

impeller (0-300 RPM) resulting in the mixing action inside a hermetically sealed bag. The

coupling of the in-bag impeller with the Drive Motor is accomplished by magnetic forces only,

therefore no dynamic seals or shaft penetration inside the bag is required. The Drive Motor is

mounted on a portable cart that can be easily disconnected from the bag and reconnected to

another mixing bag thereby allowing mixing in multiple bags of various sizes with a single Drive

Motor.

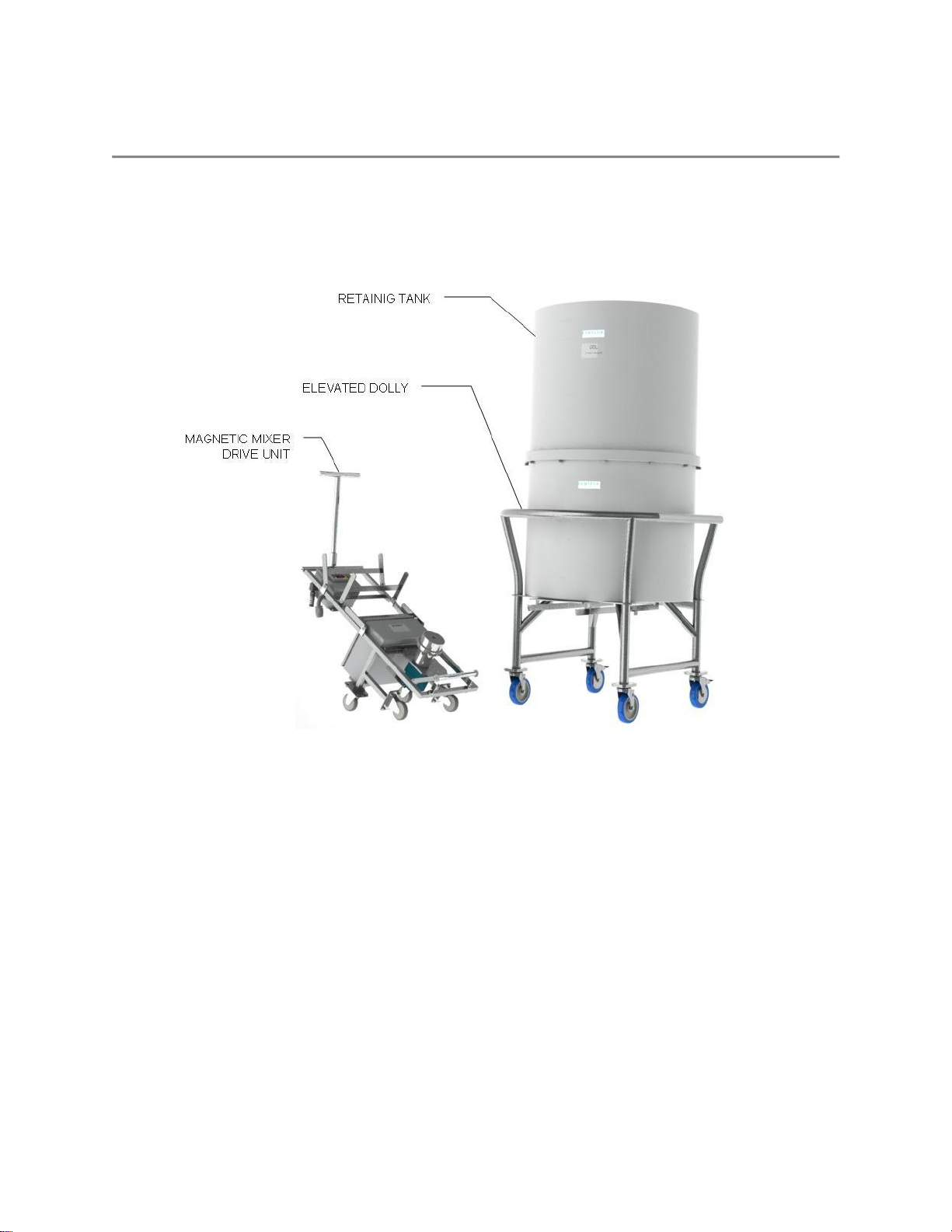

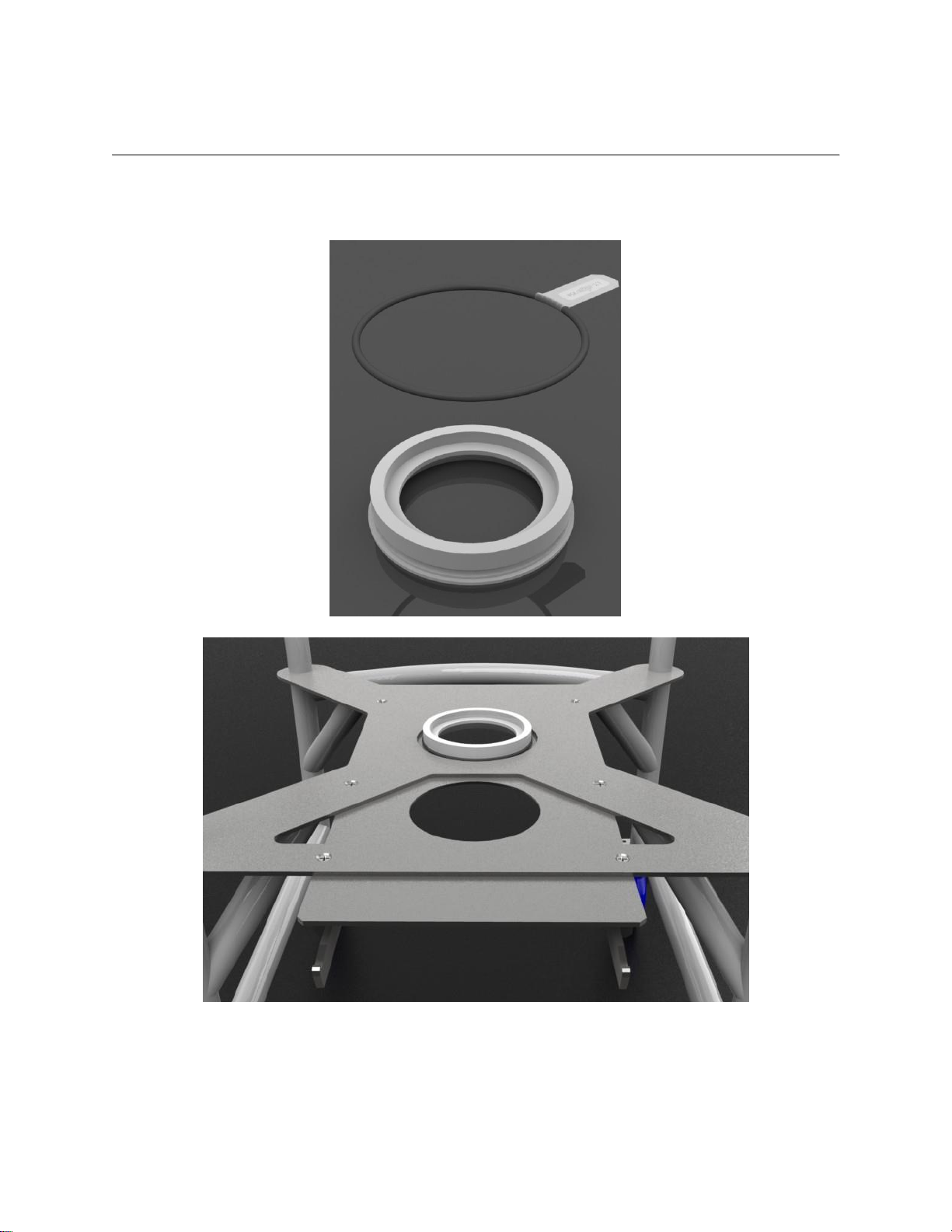

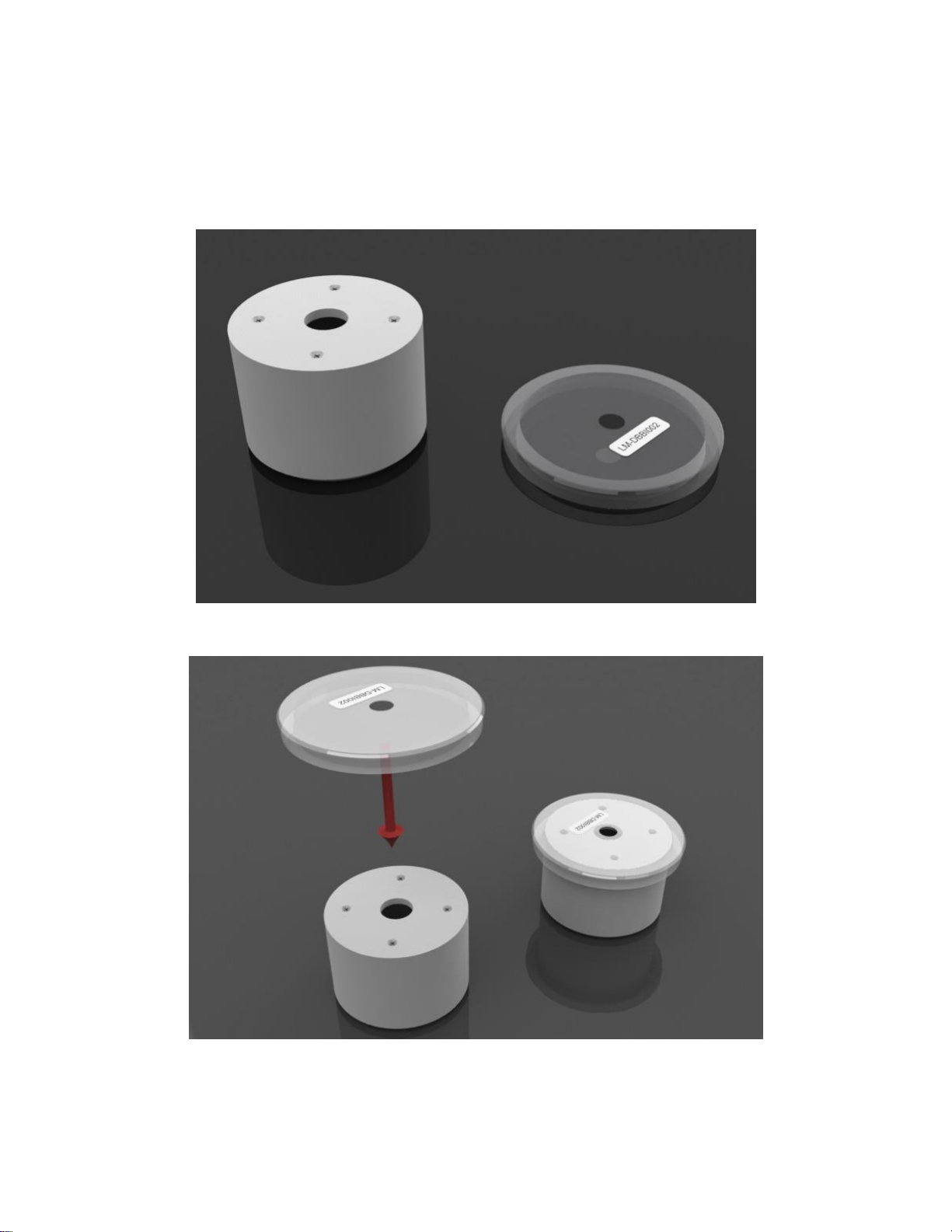

The system hardware has 4 major components:

1. Drive motor with control box and rotational speed display

2. Stainless Steel Dolly/platform for supporting the tank and interfacing with the drive

3. Plastic/Steel retaining tank for use on a dolly/stand

4. Accessory kit for interfacing the drive with the tank and bag

The Magnetic Mixer reusable system can accommodate a variety of standard and custom-

designed disposable bags and tanks available from Pall®Lifesciences with a capacity range

from 30L to 2000L.