Strap Piece

PAGE SMED SEMI VERTICAL - HUSSMANN

NOTE: For demonstration watch:

https://www.youtube.com/

watch?v=C5wPzfFSc8Q

NOTE: These cabinets are heavy, can

have high centres-of-gravity (thus

‘tippy’), use appropriate PPE and tools

and manpower levels.

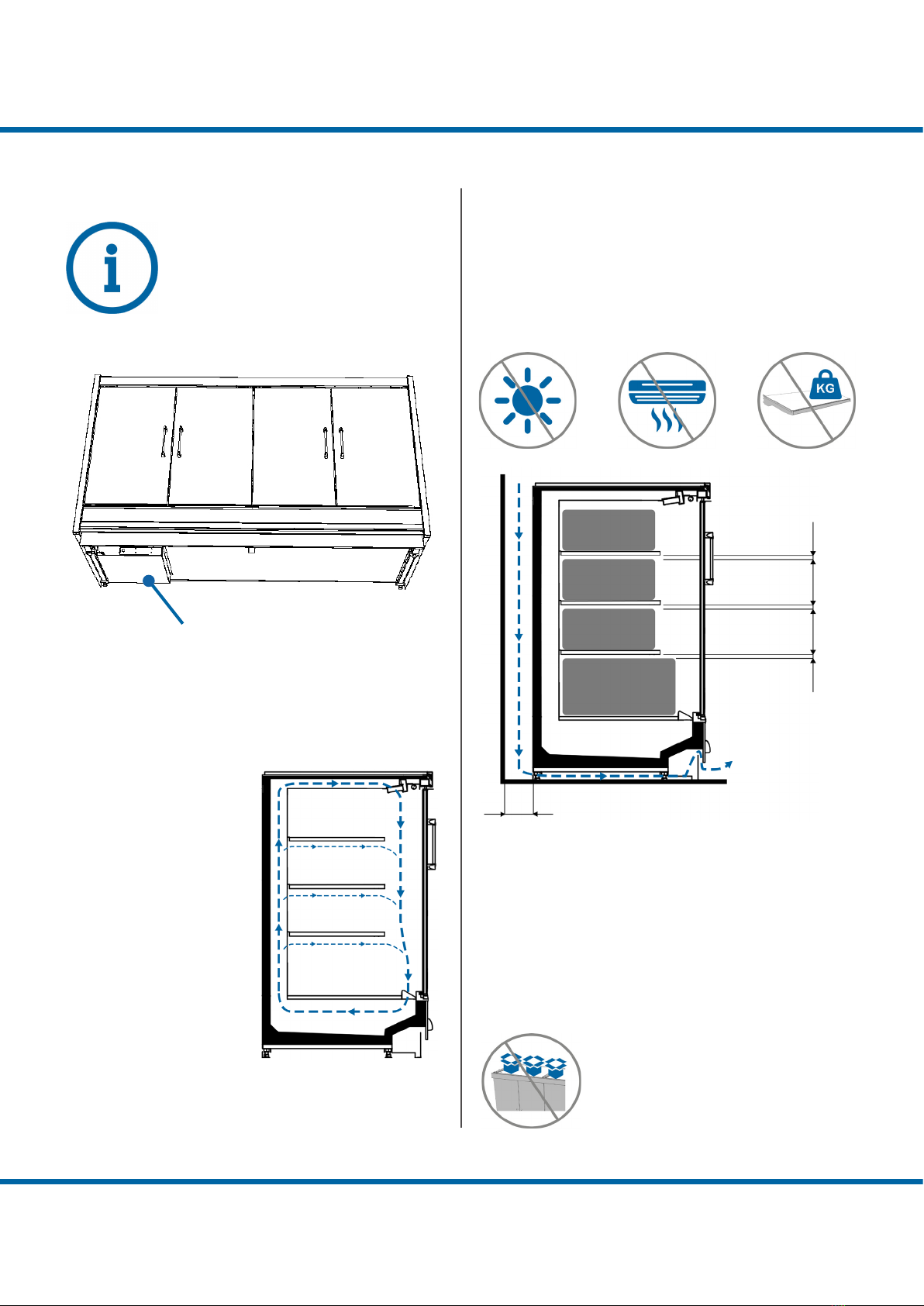

Cases have been factory tested to AS1731, +25oC at

60% RH, and cross dra of maximum 0.2m/s. For

best performance, we recommend maintaining store

temperature below +24oC at 50% RH.

To avoid condensation build-up, cases should be

positioned to allow air to freely circulate around the

underside and rear of the case (refer page 7). Cases

must be level.

Open refrigerated cases are sensitive to excessive air

disturbances. Air currents passing around cases will

seriously impair their operation. Do NOT allow air

conditioning, electric fans, open doors or windows, etc

to create air currents around the cases.

Place the case away from any heat sources as the heat

radiation and heatcurrentswillimpairtheperformance.

The exterior of these cases provide space for air

circulation. However, If the store conditions are outside

the recommended limits, a fan ventilation kit can be

requested.

Case dimensions and case weight can be found on the

rating plate. Also refer to the latest Product Engineering

Data (PED) available from Hussmann Customer Service.

Always ensure that the moving device is of a suitable

type, and has suicient liing capacity for the case

weight and dimension. Always li cases from the

underside.

It is the responsibility of the transport company to

insure adequate loading strategies are implemented to

insure the safe transportation of the Hussmann cases.

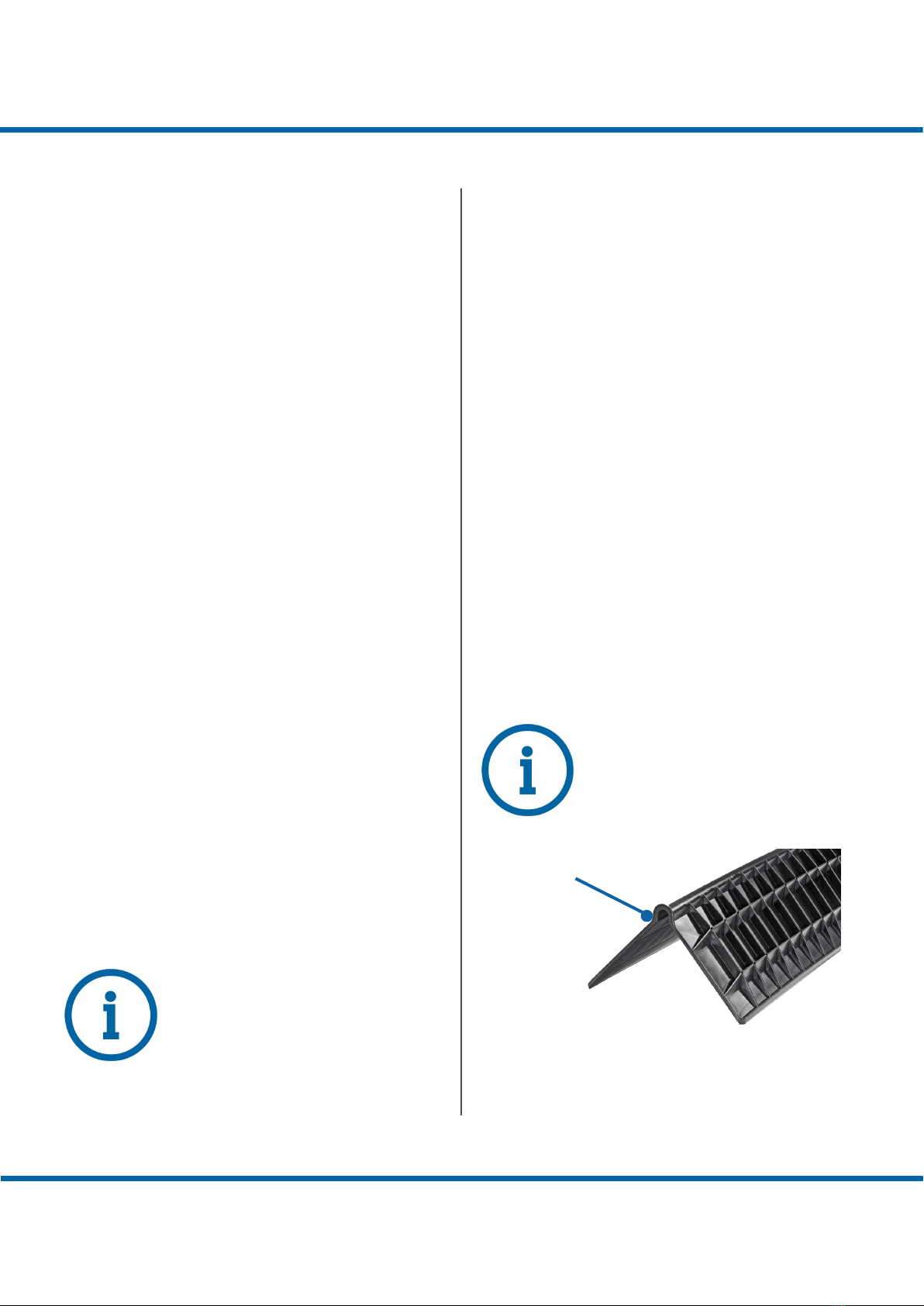

Cases should be strapped using the indicated strapping

points highlighted on the case packaging with the “strap

here” stickers’. Cases should be strapped in position

ready for transport with the appropriate rated strapping

and strap corner protector. Cases need to be secured

correctly during road transport to insure damage free

delivery. In Australia, cases should not be transported

without the strap corner protectors to insure that the tie

down web straps used from cutting into packaging and

or causing damage to case panels in transport.

The strap corner protector is a case transport

requirement in Australia, and disregarding using the

protector may cause transport damage. Without

the necessary implementation of correct strapping

protection Warehouse Managers may refuse loading.

Transportation requirements are to ensure case

integrity and prevent unnecessary damage and avoid

delays in the case installation schedule.

2.2 OPERATING ENVIRONMENT

2.3 HANDLING AND TRANSPORTING CASES

FIGURE 2B

PRE INSTALLATION