Panduit PAT4.0 Series User manual

Other Panduit Crimping Tools manuals

Panduit

Panduit ClackFin CT-3001/CCPBT User manual

Panduit

Panduit Blackfin CT-2980/TO User manual

Panduit

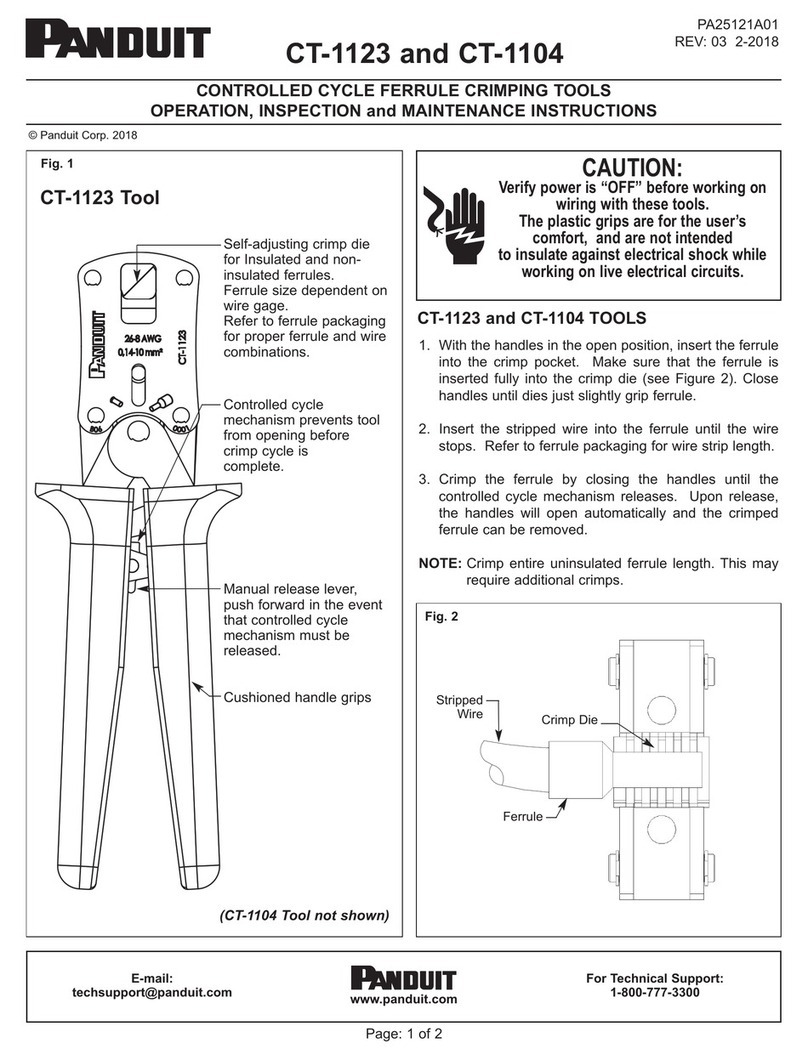

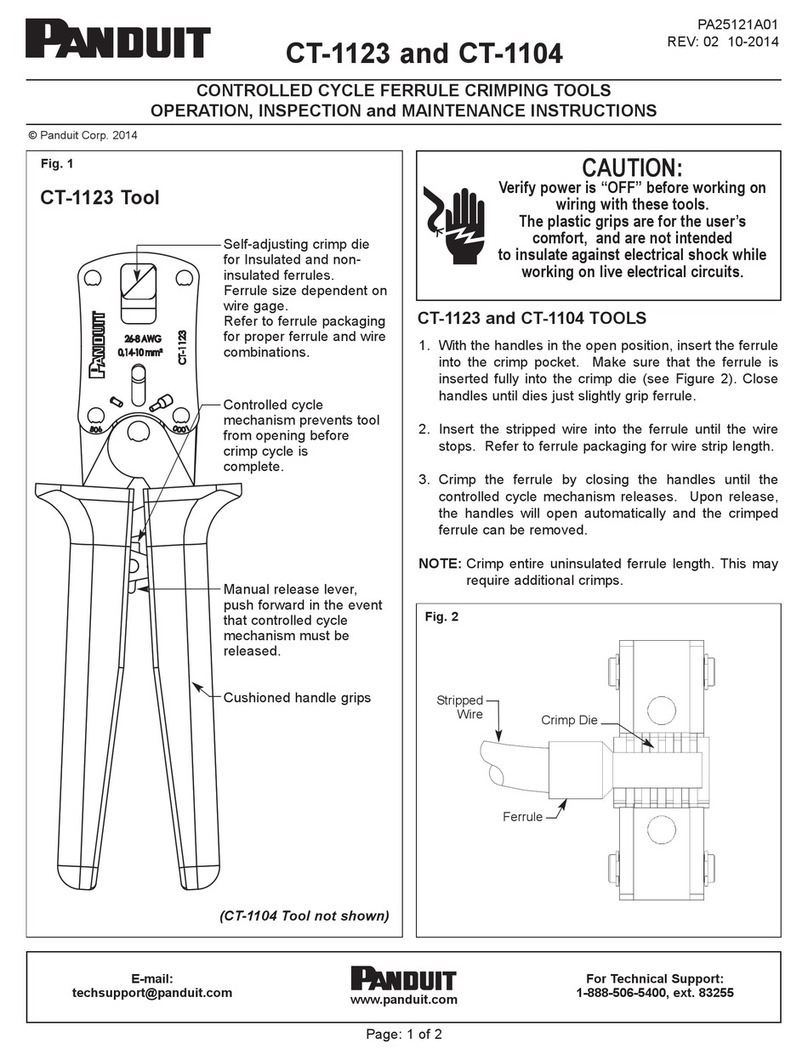

Panduit CT-1123 Instruction Manual

Panduit

Panduit CT-2940/L User manual

Panduit

Panduit CT-2002CH User manual

Panduit

Panduit BlackFin CT-2920 User manual

Panduit

Panduit BlackFin CT-2600 Series User manual

Panduit

Panduit Black Fin CT-2931 Series User manual

Panduit

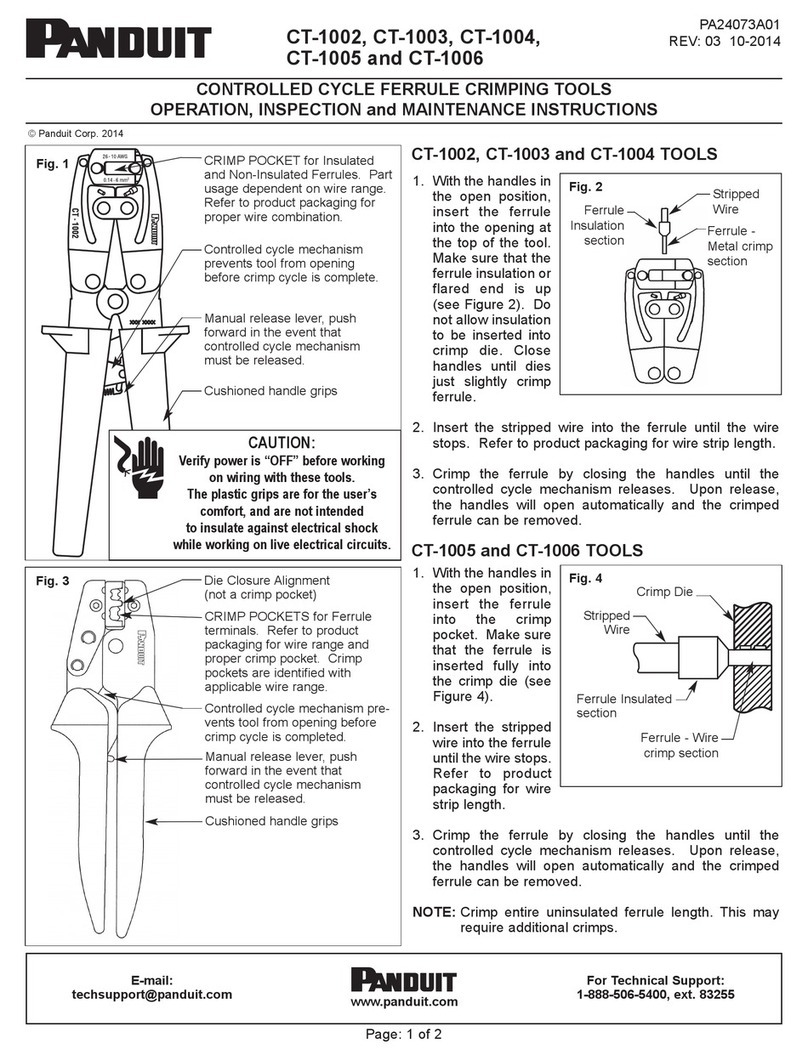

Panduit CT-1002 Manual

Panduit

Panduit BlackFin CT-2980/STBT User manual

Panduit

Panduit CT-1123 Instruction Manual

Panduit

Panduit BlackFin CT-2600/L User manual

Panduit

Panduit CT-600-A User manual

Panduit

Panduit BlackFin CT-2980/ST User manual

Panduit

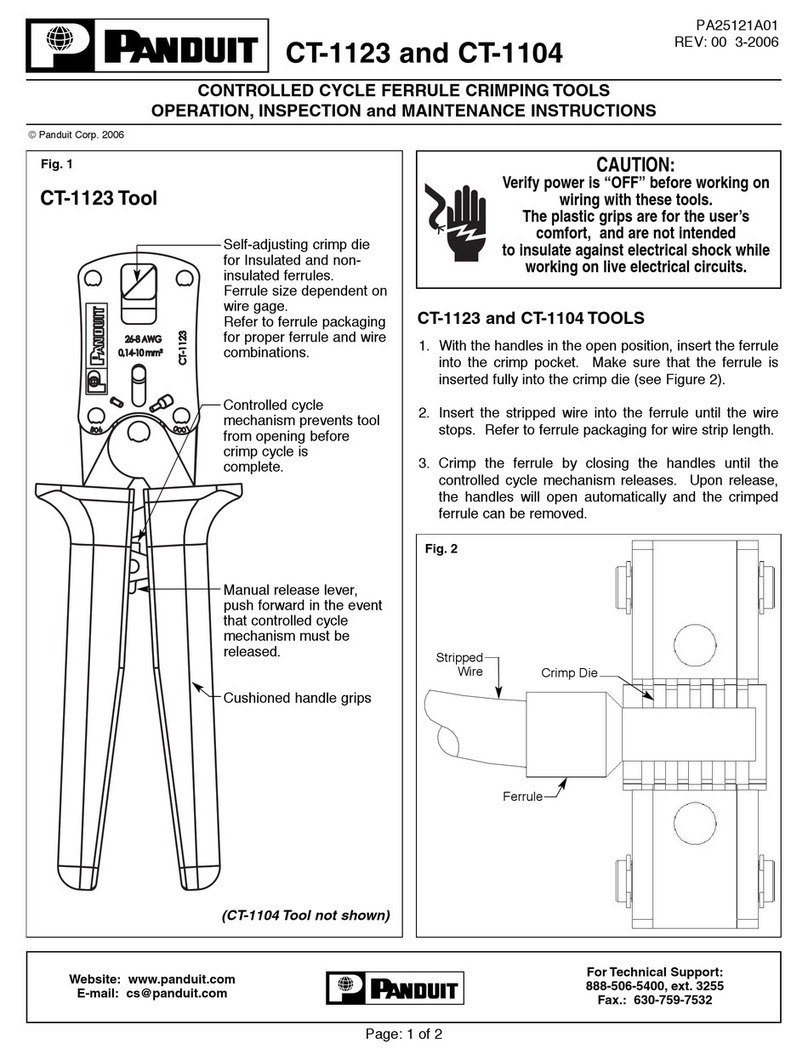

Panduit CT-1104 Instruction Manual

Panduit

Panduit CT-1003 Instruction Manual

Panduit

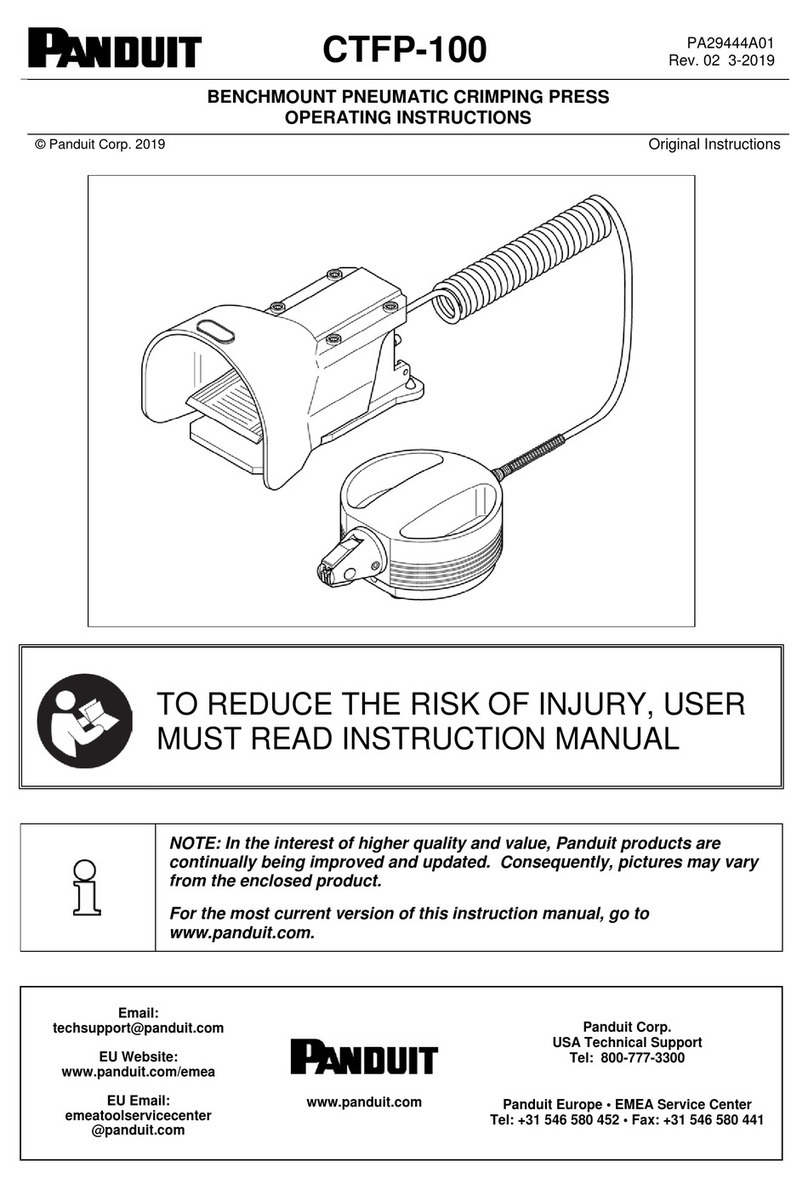

Panduit CTFP-100 User manual

Panduit

Panduit CT-460 User manual

Panduit

Panduit CT-930LPCH User manual

Panduit

Panduit Black Fin CT-2931/STCVUK User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet