Mechanical Principles

It is useful to understand the Panther P1 Dolly’s mechanical principles, in order to

avoid misusing the dolly. This is why we are noting the most important

characteristics in this operation manual.

Drive

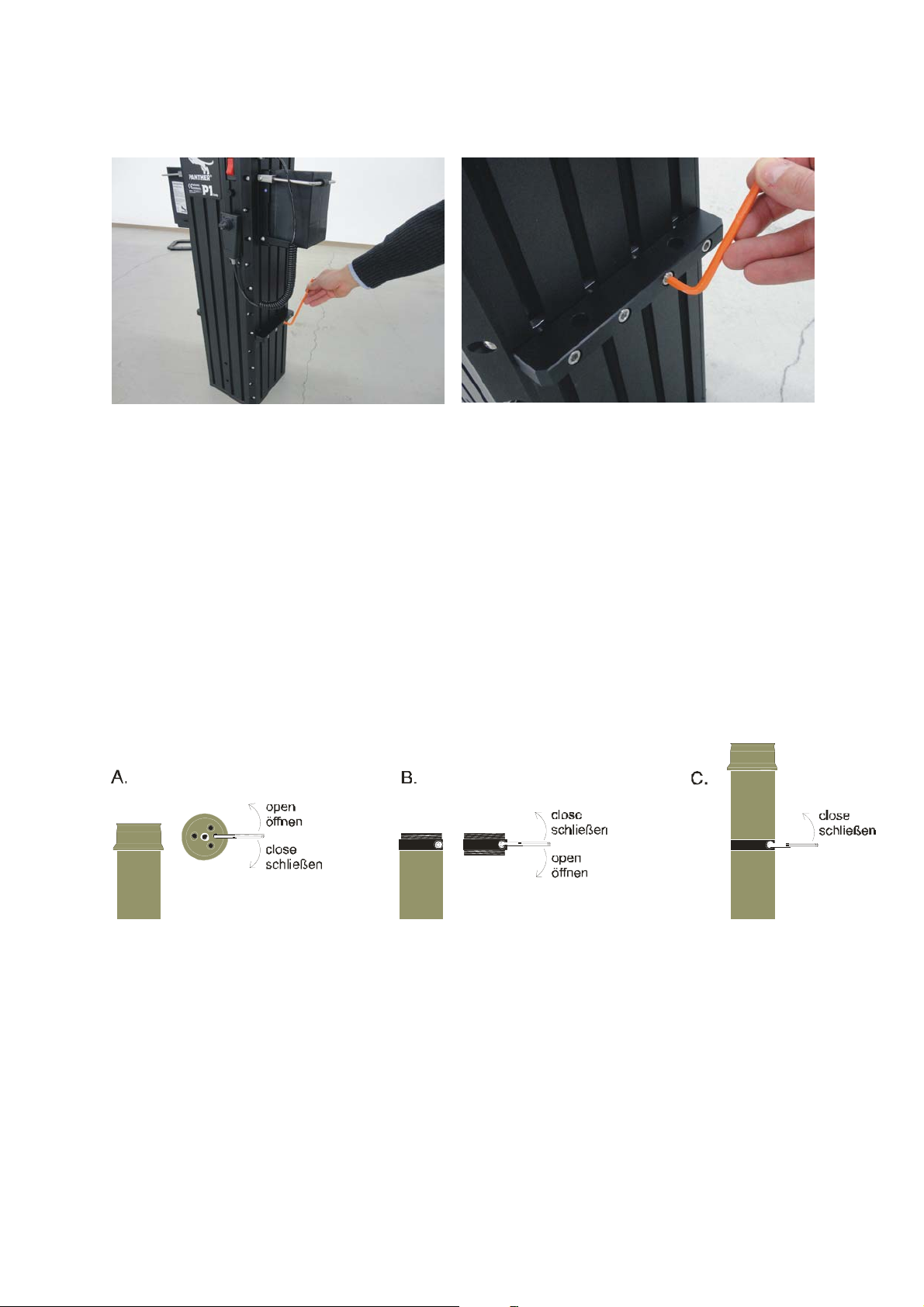

The column is moved up or down by a spindle that is located on the back side

(opposite side of main switch) of the column. This spindle is driven by a motor via a

flat belt. When in stand by operation, the column is held in position by the spindle.

Note:

When in moving operation, the motor, spindle and column tube creates mechanical

noise. This is normal and the result of mechanical friction. Moving the column at

approx. 50% of max. speed, the noise is low enough for normal shooting. If speed

goes up, the noise level rises.

Initial Operation

1. Connect batteries to P1 Column as described in „Power Supply“.

Note: Only operate the Panther P1 Dolly with fully charged batteries.

Although the batteries left our warehouse with fully charged batteries, it is possible

that a long transit time/low temperatures caused the batteries to empty. Please

check this before operation.

Fully charge the batteries before first use.

2. The Panther P1 Dolly’s (and accessories) complete lift, panning and movement

range must be cleared before switching on the dolly.

3. Check that the connection handset control to dolly is correct.

4. Switch the dolly on at the main switch.

5. Move the column up or down with the handset rocker switch.

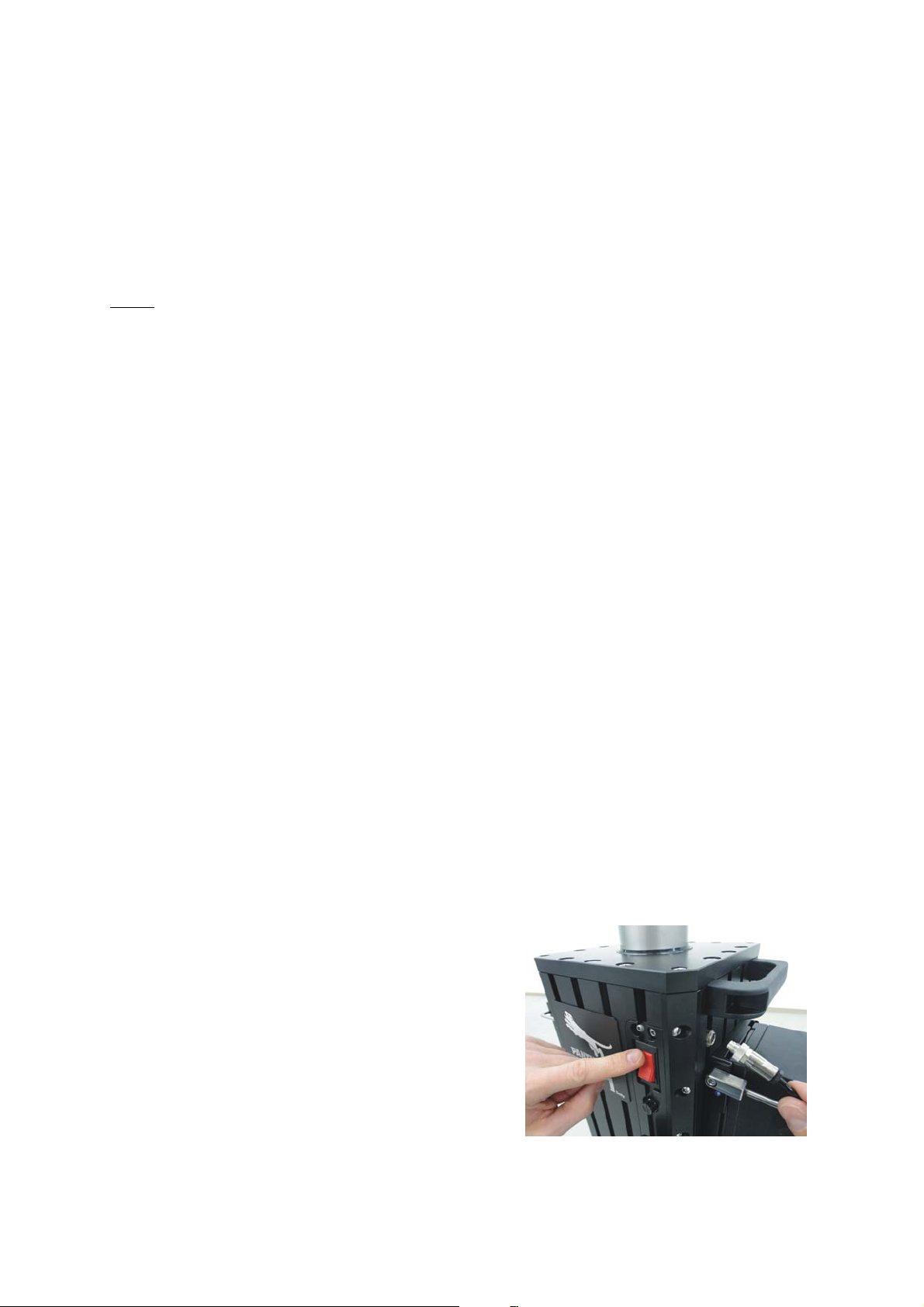

Attention:

The red main switch on the handset control also

serves as an Emergency-Off-Switch!

Column moves down in max. speed if cable

breaks or in case of disconnection.

In that case, switch off column immediately with

“Emergency-Off-Switch”.

The Panther P1 Dolly may only be operated with the original Panther batteries.